Wear-resistant materials extend the lifespan of products by minimizing damage from friction and environmental exposure. Selecting the appropriate wear-resistant coating or fabric enhances durability for industrial, automotive, or everyday applications. Explore the full article to discover how wear technology can protect Your valuable assets and improve performance.

Table of Comparison

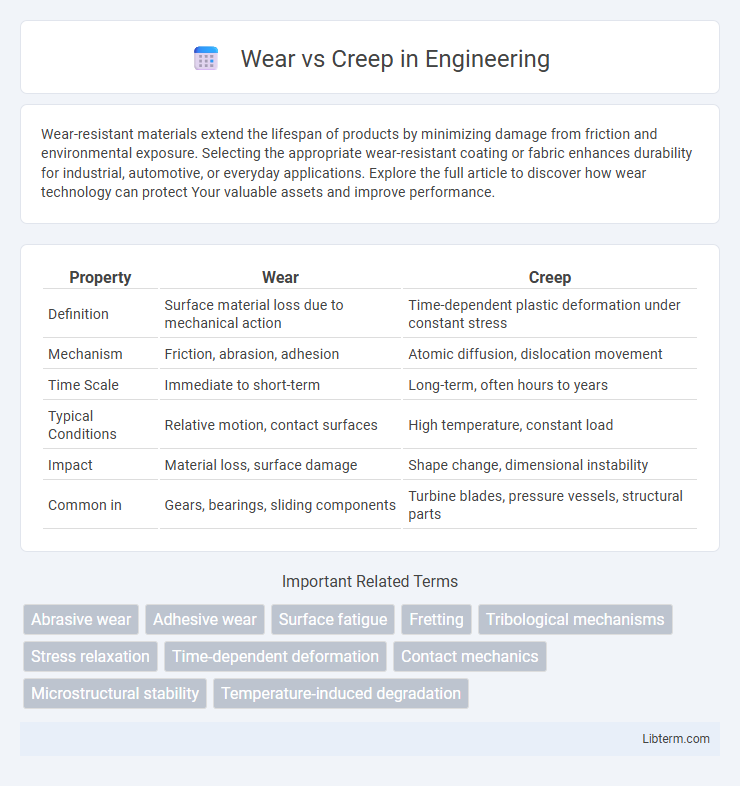

| Property | Wear | Creep |

|---|---|---|

| Definition | Surface material loss due to mechanical action | Time-dependent plastic deformation under constant stress |

| Mechanism | Friction, abrasion, adhesion | Atomic diffusion, dislocation movement |

| Time Scale | Immediate to short-term | Long-term, often hours to years |

| Typical Conditions | Relative motion, contact surfaces | High temperature, constant load |

| Impact | Material loss, surface damage | Shape change, dimensional instability |

| Common in | Gears, bearings, sliding components | Turbine blades, pressure vessels, structural parts |

Introduction to Wear and Creep

Wear is the progressive loss of material from solid surfaces due to mechanical action such as friction or abrasion, significantly affecting the durability of components in automotive and industrial applications. Creep refers to the slow, time-dependent deformation of materials under constant stress at elevated temperatures, critically influencing the lifespan of turbine blades, pipes, and other high-temperature structural elements. Understanding both wear and creep mechanisms is essential for selecting materials and designing components that maintain performance and safety under demanding operational conditions.

Defining Wear: Mechanisms and Types

Wear is the gradual removal or deformation of material surfaces due to mechanical action, typically involving friction, abrasion, adhesion, or fatigue. Common wear mechanisms include abrasive wear caused by hard particles or rough surfaces, adhesive wear resulting from material transfer between contacting surfaces, and surface fatigue wear from repeated loading cycles. Understanding these types helps in selecting materials and designing components to minimize damage and extend service life.

Understanding Creep: Causes and Characteristics

Creep is the gradual, time-dependent deformation of materials under constant stress, primarily occurring at high temperatures near the material's melting point. It results from atomic diffusion and dislocation movement, causing permanent strain that accumulates even under stress levels below the yield strength. Understanding creep characteristics such as primary, secondary, and tertiary stages aids in predicting material lifespan and preventing structural failures in components like turbine blades and pipelines.

Key Differences Between Wear and Creep

Wear involves the gradual removal of material from solid surfaces due to mechanical action such as friction or abrasion, leading to surface degradation over time. Creep refers to the slow, time-dependent deformation of materials under constant stress, typically occurring at elevated temperatures and resulting in permanent shape changes without immediate fracturing. Key differences include the nature of damage--material loss in wear versus deformation in creep--and their primary causes, with wear driven by mechanical interaction and creep by prolonged stress and thermal effects.

Factors Influencing Wear in Materials

Wear in materials is influenced by factors such as load, sliding speed, and environmental conditions like temperature and humidity. Material properties including hardness, toughness, and microstructural composition significantly affect wear resistance. Surface roughness and lubrication also play crucial roles in reducing friction-induced wear and prolonging component life.

Factors Affecting Creep Behavior

Creep behavior is influenced by several key factors including temperature, applied stress, and material properties such as grain size and crystal structure. Elevated temperatures accelerate atomic diffusion, increasing creep rates, while higher applied stress enhances dislocation movement leading to faster deformation. Microstructural characteristics, including phase distribution and precipitate formation, also dictate resistance to creep, distinguishing it from wear mechanisms that primarily involve surface material removal due to friction.

Testing Methods for Wear and Creep

Wear testing methods include pin-on-disk, ball-on-flat, and abrasive wear tests, which measure material loss under frictional contact and evaluate surface degradation. Creep testing involves applying constant stress at elevated temperatures over extended periods, monitoring deformation through creep strain vs. time curves to assess long-term material stability. Both methods use precise instrumentation like extensometers and tribometers to quantify wear volume and creep strain, ensuring reliable data for material performance analysis.

Common Applications Impacted by Wear and Creep

Wear and creep significantly affect the longevity and performance of components in aerospace, automotive, and manufacturing industries. Bearings, gears, and turbine blades commonly experience wear due to frictional forces, while materials in high-temperature environments such as jet engines and power plants are prone to creep deformation. Understanding wear resistance and creep behavior is crucial for selecting materials like advanced alloys and composites that enhance durability and safety in these applications.

Strategies for Minimizing Wear and Creep

Minimizing wear involves selecting materials with high hardness and corrosion resistance, applying surface coatings such as nitriding or diamond-like carbon to reduce friction, and implementing proper lubrication techniques using synthetic or solid lubricants to maintain optimal contact conditions. To mitigate creep, especially in high-temperature applications, materials with superior creep resistance like nickel-based superalloys or ceramics are employed, alongside design considerations that reduce stress concentrations and maintain operating temperatures below critical thresholds. Combining these strategies ensures enhanced durability and performance of components subjected to mechanical and thermal stresses over extended periods.

Future Trends in Wear and Creep Research

Future trends in wear and creep research emphasize advanced materials with enhanced resistance to deformation and surface degradation under extreme conditions. Emerging technologies such as machine learning and real-time monitoring systems enable predictive maintenance and optimized material performance in aerospace, automotive, and energy sectors. Nanostructured coatings and high-entropy alloys demonstrate significant potential for reducing wear rates and creep deformation at elevated temperatures.

Wear Infographic

libterm.com

libterm.com