A pantograph is a mechanical linkage connected in a manner that allows the copying and scaling of a figure or motion. Widely used in railway vehicles to collect electrical current from overhead lines, pantographs ensure efficient energy transfer and stable contact. Discover how this essential device enhances your daily commute by reading the full article.

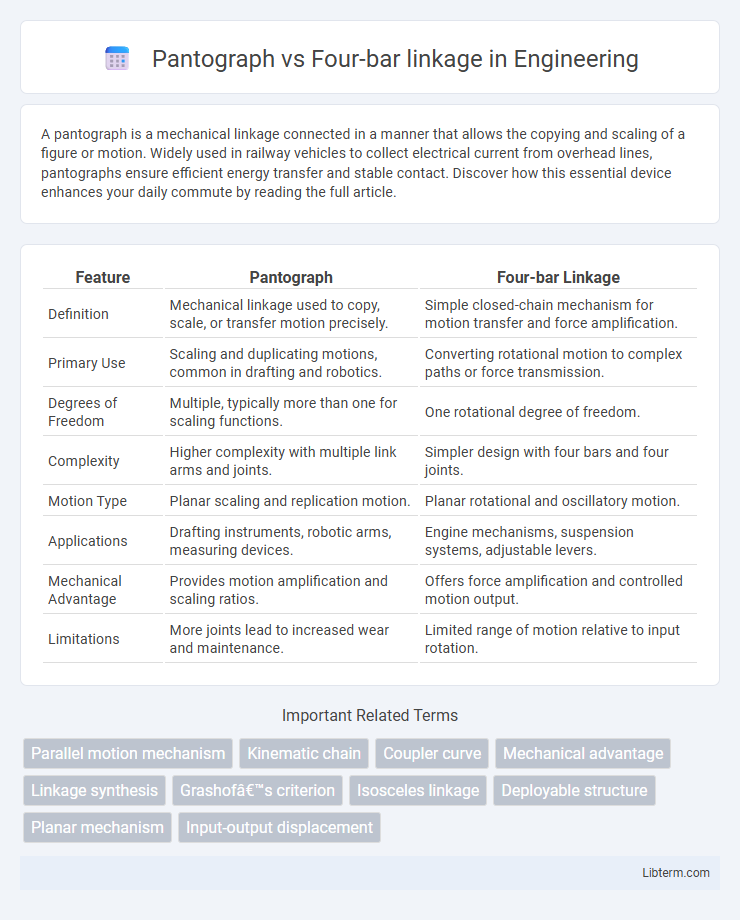

Table of Comparison

| Feature | Pantograph | Four-bar Linkage |

|---|---|---|

| Definition | Mechanical linkage used to copy, scale, or transfer motion precisely. | Simple closed-chain mechanism for motion transfer and force amplification. |

| Primary Use | Scaling and duplicating motions, common in drafting and robotics. | Converting rotational motion to complex paths or force transmission. |

| Degrees of Freedom | Multiple, typically more than one for scaling functions. | One rotational degree of freedom. |

| Complexity | Higher complexity with multiple link arms and joints. | Simpler design with four bars and four joints. |

| Motion Type | Planar scaling and replication motion. | Planar rotational and oscillatory motion. |

| Applications | Drafting instruments, robotic arms, measuring devices. | Engine mechanisms, suspension systems, adjustable levers. |

| Mechanical Advantage | Provides motion amplification and scaling ratios. | Offers force amplification and controlled motion output. |

| Limitations | More joints lead to increased wear and maintenance. | Limited range of motion relative to input rotation. |

Understanding Pantographs: Definition and Mechanism

Pantographs are mechanical linkages consisting of parallelograms that enable the scaling or copying of movements and shapes with precise proportionality. Unlike four-bar linkages, which typically provide rotational or oscillatory motion, pantographs maintain similarity transformations, making them ideal for applications like drafting and engraving. The geometric arrangement of pantograph arms ensures consistent directional movement while allowing adjustable magnification factors.

Introduction to Four-bar Linkage Systems

Four-bar linkage systems consist of four rigid bars connected by pivot joints to form a closed loop, commonly used in mechanical applications for motion transfer and force transmission. These linkages offer precise control of output motion through variations in bar lengths and pivot positions, enabling tasks such as lifting, guiding, and oscillating movements. Compared to pantographs, four-bar linkages provide simpler geometry and easier control over angular displacement, making them ideal for compact mechanical designs.

Key Components of Pantograph Mechanisms

Pantograph mechanisms consist primarily of a series of connected rigid bars arranged in parallelogram formations, which allow for proportional scaling of motion or drawings. Key components include the fixed pivot points, the movable arms, and the central linking bars that maintain geometric similarity during movement. Unlike four-bar linkages, pantographs emphasize precise geometric copying and amplification by maintaining constant angular relationships between the arms.

Main Features of Four-bar Linkage Designs

Four-bar linkage designs consist of four rigid bars connected by four rotating pairs, forming a closed loop that enables complex motion paths and force transmission. These linkages are commonly used in mechanical systems for applications such as robotic arms, suspension systems, and engine mechanisms due to their ability to convert rotary motion into oscillating or reciprocating motion efficiently. Key features include precise control over motion output, high mechanical advantage, and the ability to generate a variety of complex planar movements with relatively simple construction.

Pantograph vs Four-bar Linkage: Working Principles

The pantograph operates by parallelogram linkage that maintains scale and angle, allowing precise copying and resizing of drawings or movements. The four-bar linkage consists of four rigid bars connected in a loop with four pivot joints, transforming input motion into complex output motion, often generating rotational or oscillatory movement. Both mechanisms rely on rigid connections and pivots but differ in application: pantographs emphasize exact scale replication, while four-bar linkages focus on motion transformation and mechanical advantage.

Comparative Analysis: Precision and Accuracy

Pantographs exhibit higher precision in scaling and copying motions due to their geometric similarity properties, ensuring consistent proportional output. Four-bar linkages offer robust accuracy in controlling angular displacement and can handle more complex, constrained paths with minimal backlash. While pantographs excel in maintaining exact ratios during duplication tasks, four-bar linkages provide superior positional stability in mechanical transmissions requiring precise angular control.

Application Areas: Where Each Mechanism Excels

Pantographs excel in applications requiring precise scaling and copying of movements, such as drafting tools, engraving machines, and screen printing. Four-bar linkages are widely used in mechanical systems demanding controlled motion transfer and complex path generation, including automotive suspensions, robotic arms, and industrial machinery. Each mechanism suits specific tasks based on their kinematic characteristics and precision needs.

Advantages and Limitations of Pantographs

Pantographs offer precise scale copying and can multiply or reduce motion with high accuracy, making them ideal for drafting and engraving tasks. Their simple mechanical design allows for smooth, repeatable movement but limits flexibility to planar motions and fixed scale ratios. While pantographs excel in two-dimensional applications, their capability is constrained by less adaptability compared to more complex four-bar linkages, which can handle a wider range of movements and load distributions.

Pros and Cons of Four-bar Linkages

Four-bar linkages offer simplicity, ease of construction, and versatility in converting rotational motion into complex output motions, making them ideal for mechanical systems requiring straightforward, repeatable paths. Their limitations include restricted motion range, potential for mechanical interference, and less precision compared to pantographs in amplifying or copying movements. Despite these constraints, four-bar linkages remain cost-effective and reliable for many engineering applications.

Choosing the Right Mechanism: Factors to Consider

Selecting between a pantograph and a four-bar linkage depends on the desired motion precision and range; pantographs excel in scalable and parallel motion replication, while four-bar linkages offer versatile angular displacement and simpler construction. Load capacity, mechanical complexity, and application-specific constraints such as workspace size and required degrees of freedom significantly impact the decision. Material strength and maintenance needs also influence mechanism durability and performance in dynamic environments.

Pantograph Infographic

libterm.com

libterm.com