Abrasive machining utilizes abrasive materials to remove material from a workpiece, achieving high precision and superior surface finish. Techniques such as grinding, honing, and polishing fall under this category, enhancing component accuracy and durability. Explore the rest of the article to discover how abrasive machining can optimize your manufacturing processes.

Table of Comparison

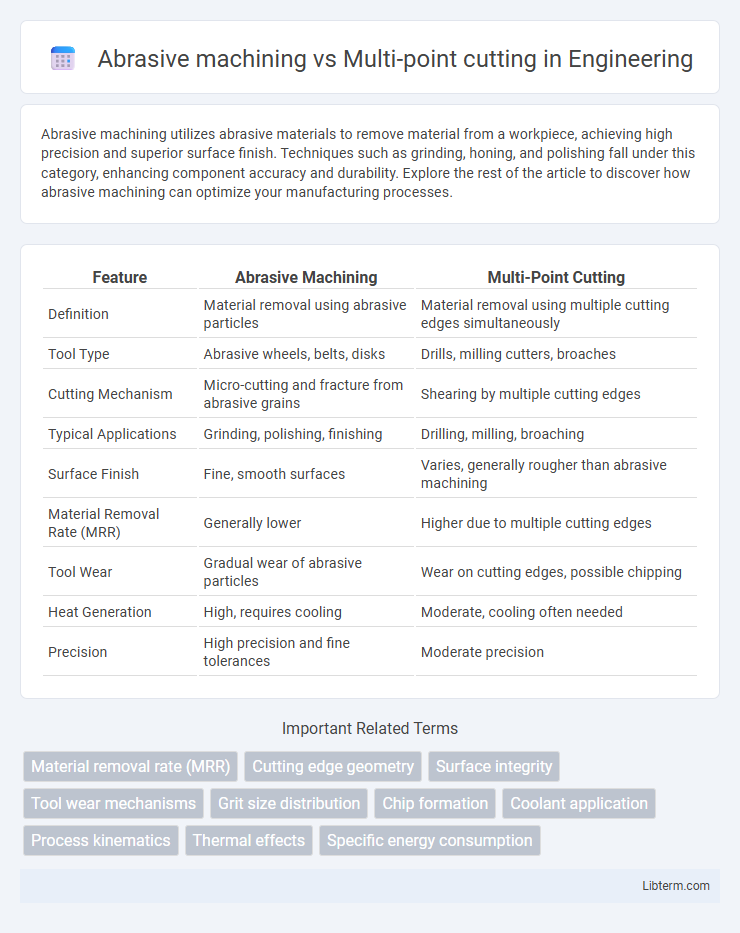

| Feature | Abrasive Machining | Multi-Point Cutting |

|---|---|---|

| Definition | Material removal using abrasive particles | Material removal using multiple cutting edges simultaneously |

| Tool Type | Abrasive wheels, belts, disks | Drills, milling cutters, broaches |

| Cutting Mechanism | Micro-cutting and fracture from abrasive grains | Shearing by multiple cutting edges |

| Typical Applications | Grinding, polishing, finishing | Drilling, milling, broaching |

| Surface Finish | Fine, smooth surfaces | Varies, generally rougher than abrasive machining |

| Material Removal Rate (MRR) | Generally lower | Higher due to multiple cutting edges |

| Tool Wear | Gradual wear of abrasive particles | Wear on cutting edges, possible chipping |

| Heat Generation | High, requires cooling | Moderate, cooling often needed |

| Precision | High precision and fine tolerances | Moderate precision |

Introduction to Abrasive Machining and Multi-point Cutting

Abrasive machining utilizes abrasive grains as cutting tools to remove material through micro-cutting and fracturing processes, ideal for hard and brittle materials. Multi-point cutting involves multiple cutting edges simultaneously engaging the workpiece, commonly seen in milling and drilling operations, enhancing material removal rates and surface finish. Both methods differ in tool design and cutting mechanics but are essential in manufacturing for precision shaping and finishing of components.

Fundamental Principles of Material Removal

Abrasive machining removes material through micro-cutting and micro-fracturing caused by hard abrasive particles pressing against the workpiece surface, emphasizing grinding, polishing, and finishing processes. Multi-point cutting employs multiple cutting edges simultaneously, distributing the load across several tools to shear material via plastic deformation and chip formation, commonly seen in milling and drilling operations. The fundamental principle difference lies in abrasive machining relying on numerous tiny cutting actions from abrasive grains, whereas multi-point cutting utilizes distinct, larger cutting edges to remove material efficiently.

Types of Abrasive Machining Processes

Abrasive machining processes include grinding, honing, lapping, and superfinishing, each utilizing abrasive particles to remove material and achieve precise surface finishes. Grinding employs rotating abrasive wheels for high material removal rates with accuracy, while honing uses abrasive stones on a rotating mandrel to improve geometrical accuracy and surface texture. Lapping involves loose abrasive particles suspended in a liquid for ultra-fine surface finishing, and superfinishing uses fine abrasives with low pressure for enhanced surface quality and dimensional accuracy.

Overview of Multi-point Cutting Processes

Multi-point cutting processes utilize multiple cutting edges simultaneously to remove material, enhancing efficiency and surface finish compared to single-point methods. Common examples include milling and drilling, where the cutting tool contains numerous teeth or flutes that engage the workpiece in a continuous or intermittent manner. This distribution of cutting forces reduces tool wear and improves heat dissipation, resulting in higher productivity and better dimensional accuracy.

Tool Material and Geometry Comparison

Abrasive machining uses loose abrasive grains or bonded abrasive wheels made from materials such as aluminum oxide or silicon carbide, featuring irregular, hard cutting surfaces that conform to workpiece contours. In contrast, multi-point cutting employs rigid, geometrically defined cutting tools typically fabricated from high-speed steel (HSS), carbide, or ceramic, designed with specific cutting edges and angles for precise chip removal. The fundamental difference lies in abrasive machining's stochastic grain geometry enabling surface refinement, versus multi-point cutting's controlled tool geometry optimized for material removal efficiency and dimensional accuracy.

Surface Finish and Accuracy Outcomes

Abrasive machining typically achieves superior surface finish due to its ability to remove material at a micro-level with fine abrasive particles, resulting in smooth and precise surfaces. Multi-point cutting, using multiple cutting edges simultaneously, often provides higher material removal rates but may produce coarser surface finishes compared to abrasive machining. Accuracy outcomes favor abrasive machining for applications requiring tight tolerances and minimal surface irregularities, while multi-point cutting balances accuracy with efficiency in less precision-critical tasks.

Process Efficiency and Productivity

Abrasive machining utilizes numerous fine grains acting as cutting edges, enabling high surface finish and precision in material removal, which enhances process efficiency in applications requiring intricate detail. Multi-point cutting involves multiple cutting edges, such as in milling or drilling, distributing cutting forces to increase productivity through faster material removal rates and reduced cycle times. Comparing the two, abrasive machining offers superior accuracy and finish for finishing processes, while multi-point cutting excels in bulk material reduction and overall throughput.

Application Areas and Industry Usages

Abrasive machining is extensively applied in industries requiring high-precision finishing and hard material processing, such as aerospace, automotive, and tool manufacturing, where grinding wheels or abrasive belts remove material at a micro-level. Multi-point cutting finds widespread usage in metalworking sectors like machining of complex components in aerospace and heavy machinery manufacturing, utilizing tools with multiple cutting edges such as milling cutters and drills for efficient material removal. Both techniques cater to specialized industrial needs, with abrasive machining excelling in surface finish and hard-to-machine materials, while multi-point cutting offers higher material removal rates and versatility in shaping complex geometries.

Advantages and Limitations of Each Method

Abrasive machining excels in achieving superior surface finishes and is ideal for shaping hard and brittle materials, offering flexibility in complex geometries but suffers from slower material removal rates and higher tool wear. Multi-point cutting methods provide faster machining speeds and improved productivity with better heat dissipation due to distributed cutting forces but may face challenges in machining very hard materials and maintaining dimensional accuracy over extended operations. Selecting between abrasive machining and multi-point cutting depends on balancing precision, surface quality, material properties, and production efficiency requirements.

Selecting the Optimal Machining Technique

Selecting the optimal machining technique depends on factors such as material hardness, surface finish requirements, and production volume. Abrasive machining excels in processing hard, brittle materials and achieving fine surface finishes through material removal by micro-cutting actions. Multi-point cutting is preferred for high-efficiency machining of ductile materials, offering rapid material removal and reduced cycle times by utilizing multiple cutting edges simultaneously.

Abrasive machining Infographic

libterm.com

libterm.com