A borehole is a deep, narrow shaft drilled into the ground to access natural resources such as water, oil, or gas. Proper construction and maintenance ensure efficient extraction and prevent contamination of surrounding environments. Discover how boreholes can be tailored to meet your specific needs by exploring the rest of this article.

Table of Comparison

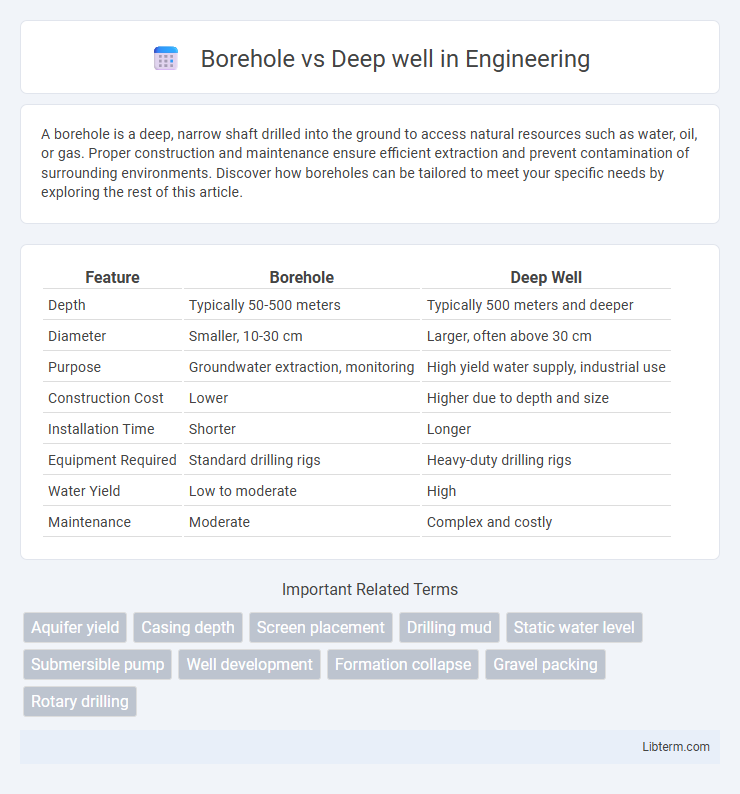

| Feature | Borehole | Deep Well |

|---|---|---|

| Depth | Typically 50-500 meters | Typically 500 meters and deeper |

| Diameter | Smaller, 10-30 cm | Larger, often above 30 cm |

| Purpose | Groundwater extraction, monitoring | High yield water supply, industrial use |

| Construction Cost | Lower | Higher due to depth and size |

| Installation Time | Shorter | Longer |

| Equipment Required | Standard drilling rigs | Heavy-duty drilling rigs |

| Water Yield | Low to moderate | High |

| Maintenance | Moderate | Complex and costly |

Introduction to Boreholes and Deep Wells

Boreholes and deep wells are engineered structures designed to access groundwater for various uses, such as agriculture, drinking water, and industrial processes. Boreholes typically refer to narrow, deep holes drilled into the ground to extract water, oil, or gas, often reaching depths from tens to several hundred meters. Deep wells, on the other hand, are specifically constructed for water extraction, often exceeding depths of 150 meters and equipped with specialized casing and pumping systems to ensure sustainable water flow from deep aquifers.

Definition and Key Differences

A borehole is a narrow, vertical shaft drilled into the ground primarily for geological exploration or groundwater extraction, typically ranging from a few inches to a few feet in diameter. A deep well is a type of borehole specifically designed for extracting water or oil and is characterized by its significant depth, often exceeding several hundred feet, to access deep aquifers or reservoirs. Key differences include the purpose--boreholes serve multiple functions such as soil sampling and environmental monitoring, while deep wells are focused on fluid extraction--and their structural design, with deep wells requiring reinforced casings and specialized pumps to manage high-pressure conditions.

Water Source and Depth Comparison

Boreholes typically reach depths of 30 to 300 meters, accessing shallow to moderately deep groundwater sources ideal for residential and agricultural use. Deep wells extend beyond 300 meters, tapping into more substantial and often cleaner aquifers, suitable for industrial water supply and municipal needs. The water source in boreholes is generally more susceptible to surface contamination, whereas deep wells draw from confined aquifers, offering higher water quality and stability.

Drilling Techniques and Equipment Used

Borehole drilling utilizes rotary or percussion rigs designed for shallow to medium depths, employing lighter equipment such as hollow stem augers or cable tool drills to efficiently penetrate softer geological formations. Deep well drilling requires advanced rotary drilling rigs equipped with drill pipes, drill bits like tri-cone or diamond bits, and heavy-duty mud pumps to manage high pressures and more complex rock strata at depths often exceeding several hundred meters. The choice of drilling technique and equipment directly impacts drilling speed, cost, and the ability to access water or resources in varying subsurface conditions.

Cost Analysis: Borehole vs Deep Well

Boreholes typically have lower drilling and installation costs compared to deep wells due to their shallower depth, ranging from 50 to 150 meters versus deep wells which often exceed 150 meters. Maintenance expenses for boreholes tend to be less, but deep wells provide higher water yield and greater long-term efficiency, potentially offsetting initial investment. Evaluating regional drilling costs, water demand, and lifespan is critical to determine the most cost-effective option between boreholes and deep wells.

Water Quality and Purity Considerations

Boreholes typically access shallower groundwater sources, which may be more susceptible to contamination from surface pollutants, affecting water quality and purity. Deep wells reach aquifers located hundreds of meters below the surface, often yielding cleaner, naturally filtered water with lower levels of bacteria and nitrates. Proper casing and sealing in both boreholes and deep wells are essential to prevent surface contamination and maintain safe drinking water standards.

Maintenance and Longevity

Boreholes generally require less frequent maintenance compared to deep wells due to their shallower depth and simpler construction but may be more susceptible to surface contamination, necessitating regular inspections for water quality and casing integrity. Deep wells, while more expensive and complex to maintain because of their depth and advanced pumping systems, often provide more reliable water sources with longer operational lifespans when properly serviced. Maintenance of deep wells emphasizes pump servicing, casing stability, and sediment removal, directly influencing the longevity and consistent performance of the water supply system.

Environmental Impact Assessment

Borehole drilling typically causes less environmental disturbance than deep wells due to shallower depths and smaller diameters, minimizing land disruption and groundwater contamination risks. Deep wells often require extensive drilling through multiple geological layers, potentially leading to higher risks of aquifer cross-contamination and greater habitat disruption. Environmental Impact Assessments (EIA) for both should emphasize groundwater quality monitoring, ecosystem preservation, and proper waste management to mitigate adverse effects.

Suitability for Different Applications

Boreholes are ideal for shallow groundwater extraction, commonly used in agricultural irrigation and domestic water supply where water tables are relatively close to the surface. Deep wells reach much greater depths, accessing confined aquifers with higher pressure, making them suitable for industrial use, municipal water systems, and regions with deep or scarce groundwater sources. The choice between borehole and deep well depends on factors like required water volume, aquifer depth, and application scale.

Choosing Between Borehole and Deep Well

Choosing between a borehole and a deep well depends on factors such as water availability, geological conditions, and intended usage. Boreholes are typically shallower, cost-effective options suitable for moderate water needs and softer soil layers, while deep wells penetrate further into groundwater reservoirs, offering higher yield and reliability in arid regions or areas with complex geology. Evaluating local water table depth, drilling costs, and water demand is essential to determine the most efficient and sustainable water extraction method.

Borehole Infographic

libterm.com

libterm.com