Creep behavior involves slow, continuous deformation under a constant load, commonly affecting materials like metals and polymers at high temperatures. Understanding creep is essential for predicting the lifespan and safety of mechanical components exposed to prolonged stress. Explore this article to learn how creep impacts your materials and the methods to mitigate its effects.

Table of Comparison

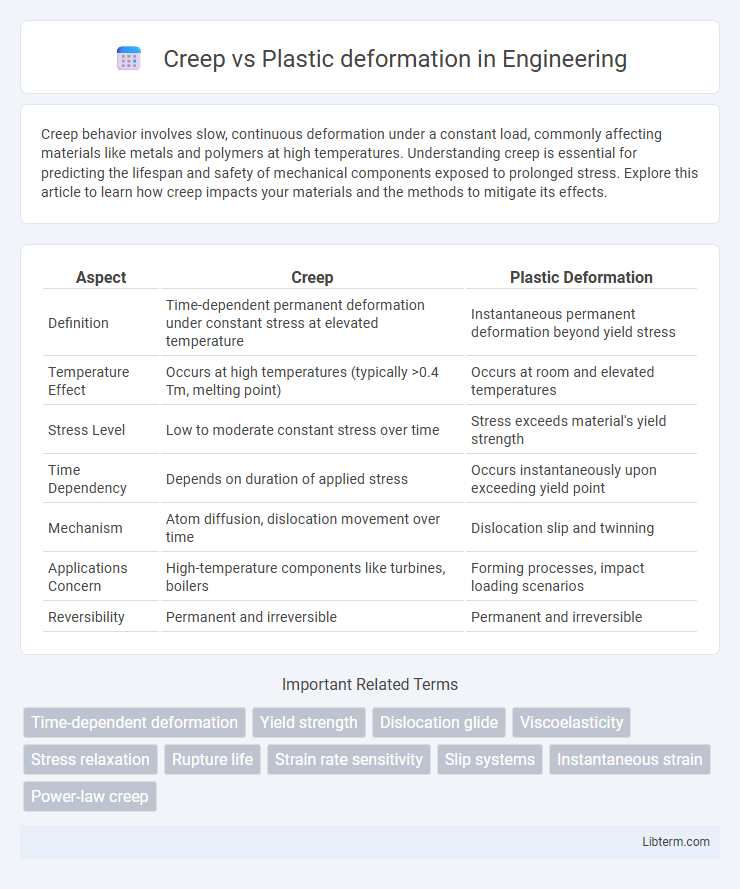

| Aspect | Creep | Plastic Deformation |

|---|---|---|

| Definition | Time-dependent permanent deformation under constant stress at elevated temperature | Instantaneous permanent deformation beyond yield stress |

| Temperature Effect | Occurs at high temperatures (typically >0.4 Tm, melting point) | Occurs at room and elevated temperatures |

| Stress Level | Low to moderate constant stress over time | Stress exceeds material's yield strength |

| Time Dependency | Depends on duration of applied stress | Occurs instantaneously upon exceeding yield point |

| Mechanism | Atom diffusion, dislocation movement over time | Dislocation slip and twinning |

| Applications Concern | High-temperature components like turbines, boilers | Forming processes, impact loading scenarios |

| Reversibility | Permanent and irreversible | Permanent and irreversible |

Introduction to Creep and Plastic Deformation

Creep is time-dependent, permanent deformation occurring in materials subjected to constant stress at high temperature, typically above 0.4 times their melting point. Plastic deformation involves permanent shape change due to applied stress beyond the elastic limit, occurring rapidly without time dependency, primarily at room or lower temperatures. Understanding the distinctions in mechanism and conditions between creep and plastic deformation is critical for materials engineering and high-temperature applications.

Definitions: Creep vs Plastic Deformation

Creep refers to the time-dependent, gradual deformation of a material under a constant load or stress, typically occurring at high temperatures relative to the material's melting point. Plastic deformation is the permanent, non-recoverable change in shape or size of a material caused by applied stress exceeding the yield strength, usually occurring instantly or within a short time frame. Understanding the distinction between creep and plastic deformation is essential for predicting material behavior in mechanical engineering and materials science applications.

Fundamental Mechanisms

Creep deformation occurs gradually over time under constant stress, primarily driven by diffusion processes such as dislocation climb and grain boundary sliding at elevated temperatures. Plastic deformation results from the immediate movement of dislocations within the crystal lattice when applied stress exceeds the yield strength, leading to permanent shape change. The fundamental distinction lies in creep's time-dependent atomic diffusion mechanisms versus plasticity's rapid dislocation glide and multiplication under stress.

Key Differences in Material Behavior

Creep and plastic deformation differ significantly in how materials respond to stress over time, with creep involving time-dependent, gradual strain under constant stress, typically at high temperatures, and plastic deformation referring to immediate, permanent shape changes once the yield stress is exceeded. Creep behavior is characterized by three stages--primary, secondary, and tertiary--each indicating changes in strain rate, while plastic deformation occurs almost instantaneously without distinct stages. The mechanisms underlying creep involve atomic diffusion and dislocation movement under sustained stress, whereas plastic deformation primarily results from dislocation slip and twinning under applied loads exceeding the elastic limit.

Factors Influencing Creep and Plastic Deformation

Creep and plastic deformation are influenced by factors such as temperature, stress level, material microstructure, and time under load. Higher temperatures and sustained stresses accelerate creep by promoting atomic diffusion and dislocation movement, while plastic deformation primarily depends on stress surpassing the yield strength and the presence of dislocation sources. Grain size, strain rate, and alloy composition critically affect the susceptibility and rate of both creep and plastic deformation processes.

Temperature and Time Dependency

Creep deformation occurs over an extended period under constant stress at elevated temperatures, typically above 0.4 times the material's melting point, causing time-dependent strain accumulation. Plastic deformation, by contrast, happens almost instantaneously once the yield stress is exceeded, and is generally temperature-independent or only slightly affected by temperature under standard conditions. Understanding the temperature and time dependency differences between creep and plastic deformation is essential for predicting material behavior in high-temperature applications like turbine blades and pressure vessels.

Industrial and Engineering Applications

Creep and plastic deformation are critical considerations in industrial and engineering applications where materials endure prolonged stress at elevated temperatures, such as turbine blades and pressure vessels. Creep involves time-dependent, irreversible strain under constant load, influencing the longevity and safety of components operating in environments exceeding 0.4 times their melting temperature (in Kelvin). Plastic deformation, characterized by immediate permanent strain upon surpassing yield stress, is pivotal in forming processes like metal stamping and forging, affecting material strength, fatigue resistance, and dimensional accuracy in manufacturing.

Real-world Examples and Case Studies

Creep deformation is commonly observed in turbine blades of jet engines where prolonged exposure to high temperatures causes slow, permanent strain, affecting performance and safety. In contrast, plastic deformation is evident in automotive crash zones where rapid, irreversible shape changes absorb impact energy to protect occupants. Case studies of nuclear reactors reveal that materials under constant stress and elevated temperatures experience creep, while bridges subjected to sudden heavy loads demonstrate plastic deformation in steel components.

Testing Methods and Measurement Techniques

Creep and plastic deformation are evaluated using specific testing methods such as constant load creep tests for creep, where strain is measured over prolonged periods under sustained stress, and tensile tests for plastic deformation, capturing immediate strain under increasing stress until yield point. Measurement techniques often employ extensometers or strain gauges to record elongation and deformation rates precisely, while microscopic analysis and hardness testing help assess microstructural changes and permanent deformation characteristics. Advanced digital image correlation (DIC) systems enable high-resolution strain mapping, enhancing the accuracy of deformation behavior characterization for both creep and plasticity studies.

Conclusion: Choosing the Right Material

Selecting the appropriate material depends on the operating environment's temperature and stress conditions, as creep predominantly affects materials under high temperature and prolonged stress, whereas plastic deformation occurs under immediate or high stress regardless of temperature. Materials with high creep resistance, such as superalloys and ceramics, are essential for high-temperature applications, while metals with high yield strength and ductility are preferable where plastic deformation is the main concern. Understanding the specific mechanical demands and environmental factors ensures optimal material performance and longevity.

Creep Infographic

libterm.com

libterm.com