Reaction engineering focuses on designing and optimizing chemical reactors to maximize efficiency and product yield by understanding reaction kinetics and transport phenomena. By carefully controlling temperature, pressure, and reactant concentrations, engineers can tailor processes to meet industrial and environmental demands. Explore further to discover how reaction engineering principles can enhance your chemical manufacturing processes.

Table of Comparison

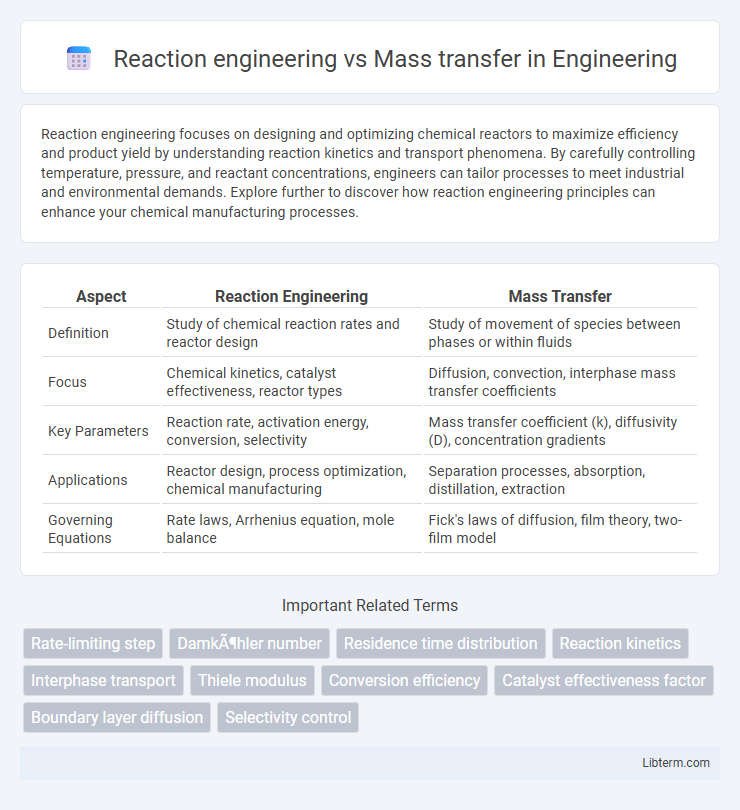

| Aspect | Reaction Engineering | Mass Transfer |

|---|---|---|

| Definition | Study of chemical reaction rates and reactor design | Study of movement of species between phases or within fluids |

| Focus | Chemical kinetics, catalyst effectiveness, reactor types | Diffusion, convection, interphase mass transfer coefficients |

| Key Parameters | Reaction rate, activation energy, conversion, selectivity | Mass transfer coefficient (k), diffusivity (D), concentration gradients |

| Applications | Reactor design, process optimization, chemical manufacturing | Separation processes, absorption, distillation, extraction |

| Governing Equations | Rate laws, Arrhenius equation, mole balance | Fick's laws of diffusion, film theory, two-film model |

Introduction to Reaction Engineering and Mass Transfer

Reaction engineering examines the rates of chemical reactions and their mechanisms, emphasizing reactor design to optimize product yield and selectivity. Mass transfer focuses on the movement of chemical species within different phases, essential for separation processes and efficient mixing. Both disciplines intersect in processes where reaction rates are influenced by species transport, requiring integrated analysis for industrial applications.

Fundamental Concepts of Reaction Engineering

Reaction engineering focuses on the design and optimization of chemical reactors by analyzing reaction kinetics, thermodynamics, and reactor types to maximize product yield and selectivity. It relies on fundamental concepts such as rate laws, reaction mechanisms, and conversion to predict reactor performance under varying conditions. Mass transfer deals with the physical movement of species within phases or across interfaces, which can influence reaction rates but is secondary to the chemical kinetics-driven approach central to reaction engineering.

Core Principles of Mass Transfer

Mass transfer involves the movement of mass from one location to another, driven by concentration gradients and governed by principles such as diffusion, convection, and mass transfer coefficients. Reaction engineering focuses on optimizing chemical reactions through kinetics and reactor design, while mass transfer principles ensure efficient transport of reactants and products to and from reaction sites. Core principles of mass transfer include Fick's laws of diffusion, the concept of boundary layers, and the use of dimensionless numbers like the Sherwood number for predicting transfer rates.

Key Differences Between Reaction Engineering and Mass Transfer

Reaction engineering focuses on the design and optimization of chemical reactors by analyzing reaction kinetics, thermodynamics, and catalyst performance, while mass transfer deals with the movement of species between phases or within phases, governed by diffusion, convection, and phase equilibrium. Key differences include reaction engineering's emphasis on chemical transformations and conversion rates, whereas mass transfer emphasizes the transport phenomena controlling species distribution and phase interfaces. Reaction engineering integrates chemical reaction rates with fluid flow, but mass transfer primarily addresses concentration gradients and interfacial mass flux.

Roles in Chemical Process Design

Reaction engineering focuses on designing reactors to optimize chemical conversion rates and selectivity by controlling parameters such as temperature, pressure, and catalyst presence. Mass transfer plays a critical role in ensuring effective transport of reactants and products within phases or across phase boundaries, impacting reaction efficiency and equilibrium. Integrating reaction kinetics with mass transfer rates enables accurate modeling and scale-up of chemical processes for optimal performance and safety.

Interplay Between Reaction Kinetics and Mass Transport

The interplay between reaction kinetics and mass transfer critically influences reactor performance, where reaction rates depend on the efficient transport of reactants to active sites. Mass transfer limitations can cause concentration gradients, reducing the effective reaction rate and altering selectivity in catalytic processes. Optimizing both reaction engineering parameters and mass transport phenomena ensures maximum conversion efficiency and enhances overall system productivity.

Common Applications in Industry

Reaction engineering plays a crucial role in designing and optimizing chemical reactors for industries such as pharmaceuticals, petrochemicals, and polymer production by maximizing reaction rates and selectivities. Mass transfer is essential in processes like gas absorption, distillation, and solvent extraction in industries including wastewater treatment and food processing, where efficient separation and mixing of phases are critical. Both disciplines integrate to improve overall process performance, particularly in catalytic reactors and multiphase systems common in chemical manufacturing.

Challenges in Integrating Reaction Engineering and Mass Transfer

Integrating reaction engineering and mass transfer faces challenges such as accurately modeling the interplay between chemical kinetics and transport phenomena, which often occur at different scales and rates. Non-ideal flow patterns and concentration gradients complicate the prediction of reaction rates, limiting the efficiency of catalytic reactors. Scaling up from laboratory to industrial systems intensifies these issues, requiring advanced computational methods and experimental techniques to optimize mass transfer alongside reaction kinetics.

Advances in Modeling and Simulation

Advances in modeling and simulation have significantly enhanced the understanding of reaction engineering and mass transfer processes by integrating computational fluid dynamics (CFD) with kinetic models to predict reactor performance and optimize mass transfer rates. The development of multiscale models enables accurate representation of complex chemical reactions alongside transport phenomena, improving design and scale-up of industrial reactors. Machine learning algorithms further refine simulation accuracy by analyzing large datasets, accelerating innovation in catalyst design and process intensification.

Future Trends in Chemical Engineering Innovation

Future trends in chemical engineering highlight the integration of reaction engineering with advanced mass transfer techniques to enhance process efficiency and sustainability. Emerging innovations include the use of microreactors and membrane technologies that optimize catalytic reactions while minimizing energy consumption and waste. Digital twins and AI-driven models are increasingly applied to predict complex mass transfer behaviors combined with reaction kinetics, facilitating real-time process optimization and scalable industrial applications.

Reaction engineering Infographic

libterm.com

libterm.com