Roller-compacted concrete dams offer a cost-effective and durable solution for water retention and flood control, utilizing a dense concrete mix compacted by rollers for rapid construction. These dams provide enhanced structural stability and reduced permeability compared to traditional concrete methods, making them ideal for large-scale infrastructure projects. Discover how your next engineering project can benefit from roller-compacted concrete dam technology by exploring the full article.

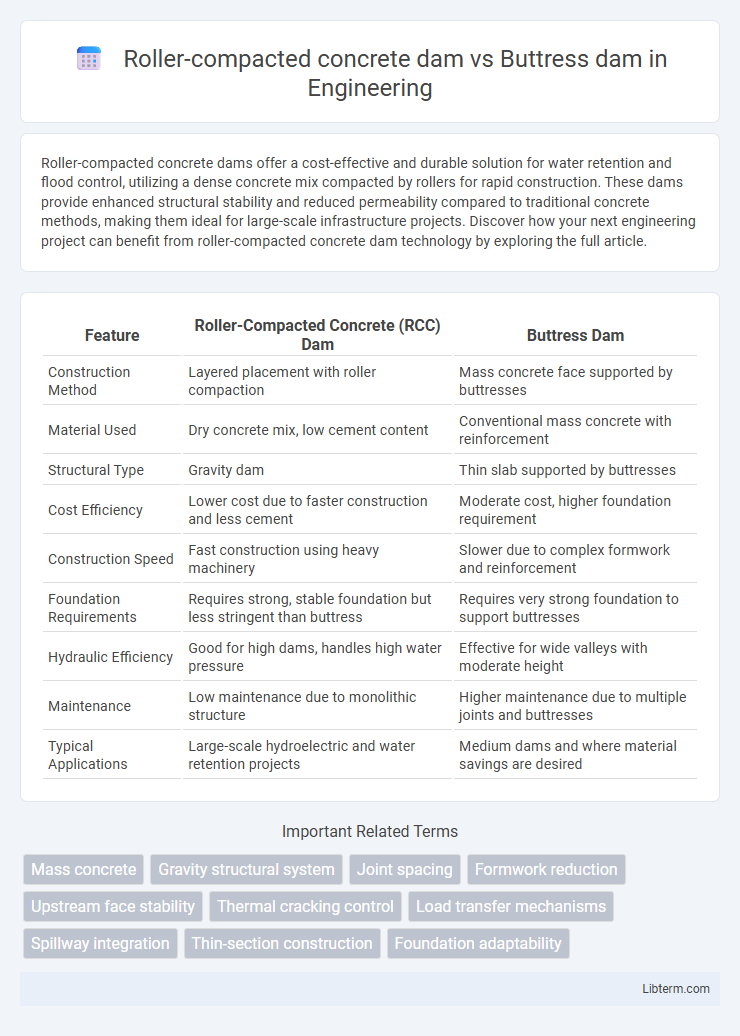

Table of Comparison

| Feature | Roller-Compacted Concrete (RCC) Dam | Buttress Dam |

|---|---|---|

| Construction Method | Layered placement with roller compaction | Mass concrete face supported by buttresses |

| Material Used | Dry concrete mix, low cement content | Conventional mass concrete with reinforcement |

| Structural Type | Gravity dam | Thin slab supported by buttresses |

| Cost Efficiency | Lower cost due to faster construction and less cement | Moderate cost, higher foundation requirement |

| Construction Speed | Fast construction using heavy machinery | Slower due to complex formwork and reinforcement |

| Foundation Requirements | Requires strong, stable foundation but less stringent than buttress | Requires very strong foundation to support buttresses |

| Hydraulic Efficiency | Good for high dams, handles high water pressure | Effective for wide valleys with moderate height |

| Maintenance | Low maintenance due to monolithic structure | Higher maintenance due to multiple joints and buttresses |

| Typical Applications | Large-scale hydroelectric and water retention projects | Medium dams and where material savings are desired |

Introduction to Dam Types

Roller-compacted concrete (RCC) dams utilize a dry mix concrete placed with heavy machinery, enabling rapid construction and high structural strength ideal for large-scale water retention projects. Buttress dams consist of a watertight upstream slab supported by a series of buttresses, offering material efficiency and reduced construction costs on solid foundations. Both dam types provide distinct engineering advantages depending on site conditions, seismic activity, and budget constraints.

Overview of Roller-Compacted Concrete Dams

Roller-compacted concrete (RCC) dams use a dry concrete mix that is placed and compacted with rollers, allowing rapid construction and reduced costs compared to traditional concrete dams. RCC dams provide high structural strength, good impermeability, and excellent durability, making them suitable for large-scale water retention projects. Their construction method contrasts with buttress dams, which rely on a series of supports to transfer water loads, resulting in a more complex design and higher material usage.

Overview of Buttress Dams

Buttress dams use a series of triangular supports, or buttresses, to transfer the water load from the dam face to the foundation, reducing the amount of concrete required compared to gravity dams. These dams are often constructed in locations with weak foundations where reducing the dam's weight is critical. The design allows for efficient material use while providing strong stability against water pressure.

Structural Design Differences

Roller-compacted concrete (RCC) dams utilize a dense, compacted concrete mixture that forms a monolithic, gravity-based structure relying on its weight to resist water pressure, featuring a relatively simple and thick design without extensive reinforcement. Buttress dams employ a series of triangular supports (buttresses) on the downstream side to transfer water loads efficiently to the foundation, allowing thinner upstream walls and reduced concrete volume through a skeletal framework. The key structural difference lies in RCC dams' massive, solid mass for stability versus buttress dams' reliance on strategically placed supports to optimize material use while maintaining strength.

Construction Process Comparison

Roller-compacted concrete (RCC) dams are built using a rapid placement method with dry concrete mixes laid down in thin layers and compacted by rollers, significantly accelerating construction time and reducing costs. In contrast, buttress dams require complex formwork and extensive concrete pouring for each buttress and the dam face, resulting in slower construction and higher labor intensity. The RCC method's mechanized process contrasts with the manual workmanship and intricate engineering essential in buttress dam construction.

Material and Cost Efficiency

Roller-compacted concrete (RCC) dams utilize a dry mix placed with earthmoving equipment, enabling faster construction and significant material savings compared to traditional concrete. Buttress dams require more formwork and conventional concrete, increasing both material usage and labor costs. RCC dams are generally more cost-efficient due to reduced cement demand and streamlined placement methods, making them preferable for large-scale projects requiring rapid completion.

Performance and Durability

Roller-compacted concrete (RCC) dams exhibit superior performance in rapid construction and high compressive strength, enabling efficient load distribution and enhanced structural stability. Buttress dams provide material efficiency with their triangular support design, offering durability through reduced concrete volume and effective water pressure management. In terms of durability, RCC dams resist abrasion and weathering due to their dense, low-permeability structure, while buttress dams require careful maintenance of joints and supports to prevent leakage and structural fatigue over time.

Environmental Impact Considerations

Roller-compacted concrete (RCC) dams typically have a lower environmental footprint than buttress dams due to their faster construction time, which reduces the period of ecosystem disruption and lowers emissions from machinery. RCC dams require less cement and steel reinforcement compared to buttress dams, minimizing raw material extraction and associated ecological damage. The compacted nature of RCC dams enhances water tightness, reducing seepage-related erosion and downstream habitat degradation commonly observed in some buttress dam designs.

Suitable Applications and Site Conditions

Roller-compacted concrete (RCC) dams are ideal for sites requiring rapid construction and cost-effectiveness, especially where foundation conditions are moderate and large volumes of concrete can be efficiently placed. Buttress dams are better suited for sites with weak foundations or where reducing the dam's weight is critical, providing structural support through multiple buttresses that transfer loads to the foundation. RCC dams excel in broad valleys with ample material availability, while buttress dams are advantageous in narrow canyons with complex geotechnical conditions.

Summary: Choosing Between RCC and Buttress Dams

Roller-compacted concrete (RCC) dams offer high strength and rapid construction, ideal for large-scale projects requiring cost efficiency and durability. Buttress dams use multiple supports to resist water pressure, allowing material savings and adaptability to variable foundation conditions. Selection depends on site-specific geological, economic, and environmental factors, where RCC suits massive, uniform foundations and buttress designs excel in complex terrains with reduced concrete volume.

Roller-compacted concrete dam Infographic

libterm.com

libterm.com