Fuzzy logic control leverages approximate reasoning to handle complex systems with uncertainty and imprecision, enabling more adaptable and robust performance compared to traditional binary logic controllers. By mimicking human decision-making, it processes inputs in degrees rather than absolutes, which improves your system's flexibility and efficiency in dynamic environments. Explore the rest of the article to discover how fuzzy logic control can optimize your applications and enhance system responsiveness.

Table of Comparison

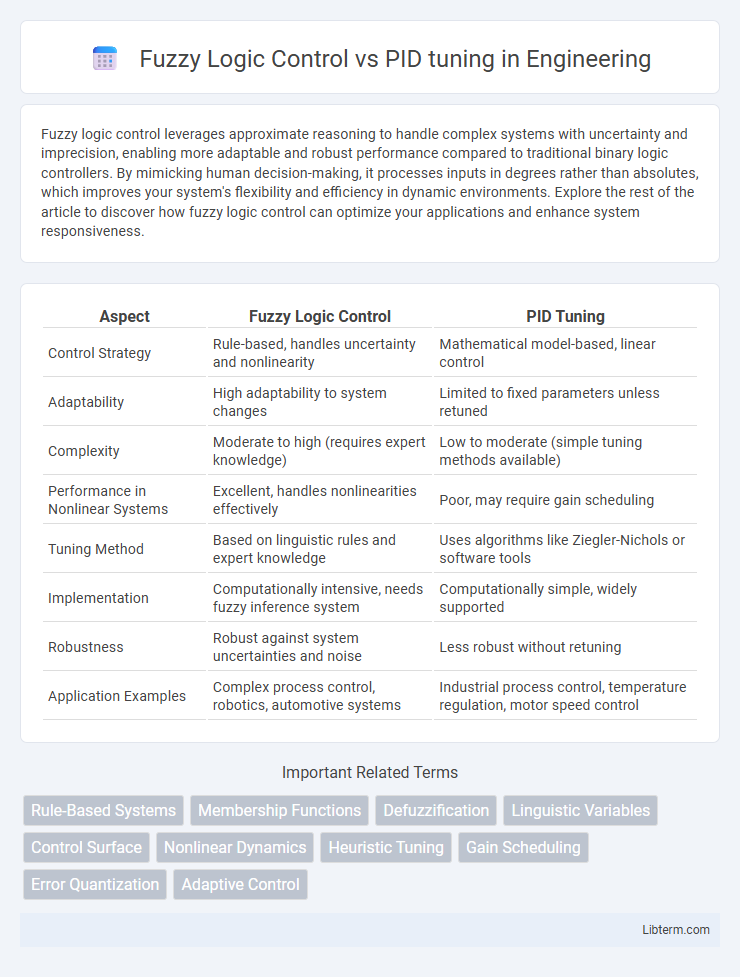

| Aspect | Fuzzy Logic Control | PID Tuning |

|---|---|---|

| Control Strategy | Rule-based, handles uncertainty and nonlinearity | Mathematical model-based, linear control |

| Adaptability | High adaptability to system changes | Limited to fixed parameters unless retuned |

| Complexity | Moderate to high (requires expert knowledge) | Low to moderate (simple tuning methods available) |

| Performance in Nonlinear Systems | Excellent, handles nonlinearities effectively | Poor, may require gain scheduling |

| Tuning Method | Based on linguistic rules and expert knowledge | Uses algorithms like Ziegler-Nichols or software tools |

| Implementation | Computationally intensive, needs fuzzy inference system | Computationally simple, widely supported |

| Robustness | Robust against system uncertainties and noise | Less robust without retuning |

| Application Examples | Complex process control, robotics, automotive systems | Industrial process control, temperature regulation, motor speed control |

Introduction to Fuzzy Logic Control and PID Tuning

Fuzzy Logic Control utilizes rule-based reasoning and linguistic variables to manage complex, nonlinear systems without requiring an exact mathematical model, making it effective for uncertain or imprecise environments. PID tuning involves adjusting proportional, integral, and derivative gains to optimize system response, ensuring stability and minimizing error in linear control systems. Both approaches aim to enhance control performance, with Fuzzy Logic excelling in adaptability and PID favored for its simplicity and well-established methodologies.

Fundamental Principles of Fuzzy Logic Control

Fuzzy Logic Control (FLC) operates on the fundamental principle of reasoning with imprecise or uncertain information using linguistic variables and fuzzy sets, enabling control based on approximate rather than exact data. Unlike PID tuning, which relies on precise mathematical models and fixed gain parameters (proportional, integral, derivative), FLC utilizes a rule-based system with if-then rules derived from expert knowledge to handle nonlinearities and system uncertainties. This approach allows FLC to maintain robust performance in complex, dynamic environments where classical PID controllers may struggle.

Core Mechanisms of PID Tuning

PID tuning relies on adjusting proportional, integral, and derivative gains to minimize error by correcting system output based on present, past, and future error trends. The proportional term addresses current error magnitude, the integral term eliminates accumulated steady-state error, and the derivative term anticipates future error by assessing its rate of change. Effective PID tuning requires balancing these core mechanisms to achieve stability, fast response, and minimal overshoot in control systems.

Comparative Analysis: Fuzzy Logic vs PID Control

Fuzzy Logic Control adapts to system nonlinearities and uncertainties through rule-based reasoning, offering superior performance in complex, imprecise environments compared to PID tuning, which relies on fixed proportional, integral, and derivative parameters optimized for linear systems. PID control excels in straightforward, stable processes due to its simplicity and ease of implementation but often requires retuning when system dynamics change, whereas Fuzzy Logic adjusts dynamically without explicit mathematical models. Studies reveal Fuzzy Logic controllers reduce overshoot and steady-state error better than PID in systems with noise and parameter variations, enhancing robustness and adaptability.

Performance in Nonlinear and Complex Systems

Fuzzy Logic Control outperforms PID tuning in nonlinear and complex systems by handling uncertainties and system nonlinearities more effectively without relying on precise mathematical models. PID controllers often struggle with performance degradation under varying operating conditions due to their linear nature and fixed parameters. Fuzzy controllers adapt dynamically, offering enhanced robustness and better control accuracy in systems characterized by nonlinearity and complexity.

Robustness and Adaptability

Fuzzy Logic Control demonstrates superior robustness and adaptability compared to traditional PID tuning by effectively handling system nonlinearities and uncertainties without requiring an exact mathematical model. It continuously adjusts control rules based on fuzzy inference, enabling adaptive performance in dynamic environments where PID controllers may struggle due to fixed parameters. Consequently, Fuzzy Logic provides enhanced stability and responsiveness in complex or varying process conditions, outperforming PID in maintaining optimal control under disturbances and parameter variations.

Implementation Complexity and Cost

Fuzzy Logic Control (FLC) implementation involves higher complexity due to the need for designing rule-based systems and membership functions, requiring expert knowledge in fuzzy set theory, which often increases development time and cost. In contrast, PID tuning benefits from simpler mathematical models and well-established algorithms, making it more cost-effective and easier to implement for most industrial control applications. The initial deployment cost of FLC can be justified in systems with nonlinearities or uncertainties where traditional PID controllers might struggle to maintain optimal performance.

Popular Applications and Use Cases

Fuzzy logic control excels in complex systems with nonlinear dynamics and uncertainties, such as robotics, automotive engines, and HVAC systems, where traditional PID controllers struggle to maintain optimal performance. PID tuning remains widely popular in industrial automation, process control, and temperature regulation, offering simplicity and effectiveness in linear, well-defined environments. Hybrid approaches combining fuzzy logic with PID tuning are increasingly adopted in advanced applications like adaptive cruise control and real-time process optimization to leverage the strengths of both methods.

Advantages and Limitations

Fuzzy Logic Control offers advantages in handling nonlinear systems and imprecise inputs due to its rule-based approach, making it highly adaptable to complex processes where PID tuning may struggle. PID tuning is effective for linear and well-understood systems, providing precise control with relatively simple implementation and proven stability, but it often requires manual adjustment and may perform poorly under varying conditions. Limitations of Fuzzy Logic include increased computational complexity and the need for expert knowledge to design membership functions, whereas PID controllers can become unstable or oscillatory if improperly tuned.

Future Trends in Control System Technologies

Fuzzy logic control offers adaptive and robust solutions for nonlinear and uncertain systems, outperforming traditional PID tuning methods in complex environments. Future trends highlight the integration of artificial intelligence and machine learning to enhance both fuzzy logic and PID controllers, enabling real-time optimization and predictive capabilities. Advances in sensor technologies and edge computing are driving the development of hybrid control systems that leverage the strengths of fuzzy logic and PID tuning for improved precision and efficiency in industrial automation.

Fuzzy Logic Control Infographic

libterm.com

libterm.com