A reluctance motor operates by minimizing magnetic reluctance, using rotor saliency to generate torque efficiently without permanent magnets or windings on the rotor. This type of motor is valued for its simplicity, reliability, and cost-effectiveness in various industrial and automotive applications. Discover how your choice of reluctance motor can enhance performance and energy savings by reading the full article.

Table of Comparison

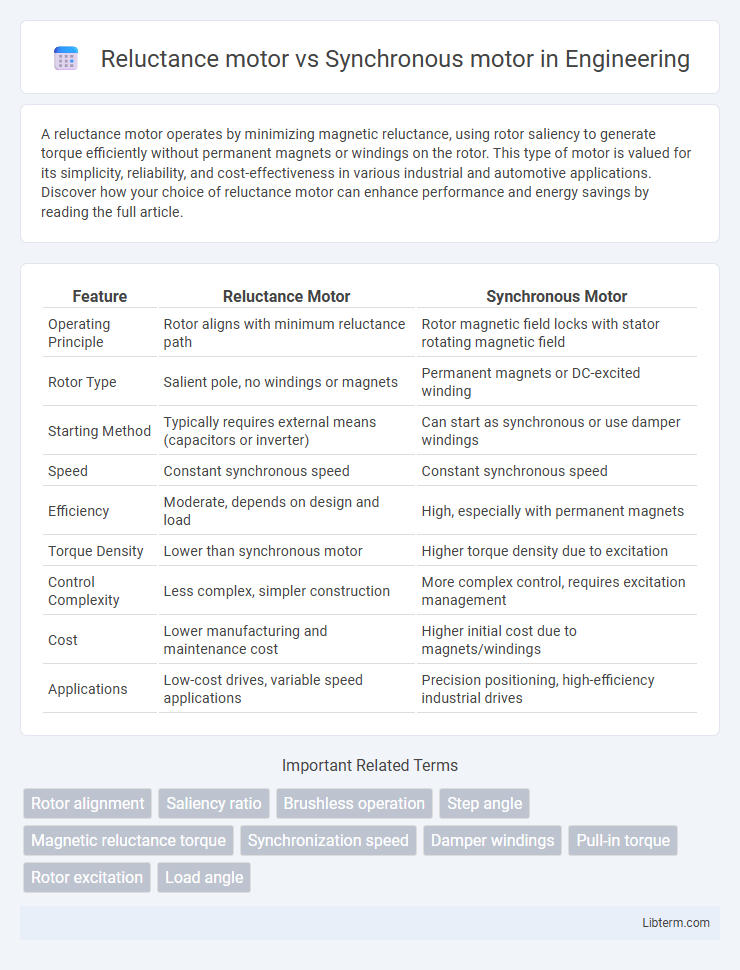

| Feature | Reluctance Motor | Synchronous Motor |

|---|---|---|

| Operating Principle | Rotor aligns with minimum reluctance path | Rotor magnetic field locks with stator rotating magnetic field |

| Rotor Type | Salient pole, no windings or magnets | Permanent magnets or DC-excited winding |

| Starting Method | Typically requires external means (capacitors or inverter) | Can start as synchronous or use damper windings |

| Speed | Constant synchronous speed | Constant synchronous speed |

| Efficiency | Moderate, depends on design and load | High, especially with permanent magnets |

| Torque Density | Lower than synchronous motor | Higher torque density due to excitation |

| Control Complexity | Less complex, simpler construction | More complex control, requires excitation management |

| Cost | Lower manufacturing and maintenance cost | Higher initial cost due to magnets/windings |

| Applications | Low-cost drives, variable speed applications | Precision positioning, high-efficiency industrial drives |

Introduction to Reluctance and Synchronous Motors

Reluctance motors operate based on the principle of magnetic reluctance, where the rotor aligns with the minimum reluctance path in the stator's magnetic field, resulting in torque production without the need for permanent magnets or rotor windings. Synchronous motors maintain a constant speed synchronous with the supply frequency, utilizing either permanent magnets or rotor windings energized by DC current to establish a steady magnetic field. Both motor types are essential in various industrial applications, with reluctance motors favored for their simplicity and synchronous motors for precise speed control and efficiency.

Basic Operating Principles

Reluctance motors operate based on the principle of minimizing magnetic reluctance by aligning their rotor with the stator's magnetic field, causing torque production without permanent magnets or windings on the rotor. Synchronous motors use a rotor with either permanent magnets or DC-excited field windings to create a constant magnetic field that locks in sync with the stator's rotating magnetic field, ensuring constant speed operation. The fundamental distinction lies in the reluctance motor's torque generation through variable magnetic reluctance, whereas the synchronous motor relies on magnetic field synchronization for torque and speed stability.

Construction Differences

Reluctance motors feature rotor designs with salient poles and no windings or permanent magnets, relying on rotor saliency to generate torque, while synchronous motors utilize rotors equipped with either permanent magnets or field windings to produce a constant magnetic field. The construction of reluctance motors emphasizes rotor simplicity to create variable reluctance paths, contrasting with synchronous motors that require excitation systems for rotor magnetizing flux. These structural variations impact performance characteristics such as starting torque, efficiency, and control complexity.

Magnetic Field and Torque Generation

Reluctance motors generate torque by minimizing magnetic reluctance through the alignment of rotor saliencies with the stator magnetic field, resulting in torque that depends on the rotor's position relative to the magnetic field. Synchronous motors produce torque by the interaction between a constant, rotating magnetic field of the stator and a rotor magnetic field that is locked in synchronous speed, typically created by permanent magnets or DC excitation. The magnetic field in reluctance motors varies according to rotor position to maximize torque, whereas synchronous motors maintain a steady magnetic field to ensure uniform torque output.

Efficiency and Performance Characteristics

Reluctance motors generally exhibit lower efficiency and torque ripple compared to synchronous motors, which maintain high efficiency due to their constant rotor speed synchronized with the stator frequency. Synchronous motors provide superior performance characteristics such as precise speed control, higher power factor, and better stability under varying load conditions. While reluctance motors are simpler and cost-effective, synchronous motors are preferred for applications demanding higher efficiency and consistent performance.

Control Methods and Starting Techniques

Reluctance motors utilize rotor position sensors and advanced pulse-width modulation (PWM) controllers for precise control, enabling efficient torque production through magnetic saliency differences, whereas synchronous motors rely on rotor field excitation and feedback from encoders or resolvers for position control. Starting techniques for reluctance motors often involve direct online starting or controlled ramp-up using inverter drives to manage torque ripple and minimize mechanical stress, while synchronous motors typically require external means such as pony motors, damper windings, or soft starters to achieve synchronous speed before excitation is applied. Both motor types benefit from vector control or field-oriented control (FOC) methods to optimize dynamic performance and efficiency during operation.

Applications in Industry

Reluctance motors are widely used in applications requiring variable speed control and high efficiency, such as HVAC systems, electric vehicles, and robotics, due to their simple construction and robust performance. Synchronous motors are preferred in industries demanding precise speed control and constant speed operation, including power generation, conveyor systems, and large compressors. The choice between reluctance and synchronous motors depends on factors like load characteristics, control complexity, and energy efficiency requirements in industrial settings.

Cost and Maintenance Considerations

Reluctance motors generally have a lower initial cost due to their simpler rotor design, which lacks permanent magnets or windings, reducing material expenses. Maintenance for reluctance motors tends to be minimal because of fewer components subject to wear and less complex construction. Synchronous motors, while typically more expensive upfront, may incur higher maintenance costs related to excitation systems and rotor components, especially in applications requiring precise speed control.

Advantages and Limitations Comparison

Reluctance motors offer advantages such as simple construction, robust operation, and low cost due to the absence of permanent magnets or windings on the rotor, making them highly reliable and maintenance-friendly. Synchronous motors provide precise speed control and high efficiency with constant speed operation under varying loads, benefiting applications requiring accurate timing and power factor correction. However, reluctance motors suffer from torque ripple and lower power density, while synchronous motors require external excitation or permanent magnets, increasing complexity and cost.

Future Trends and Technological Advances

Reluctance motors are gaining traction due to their simple construction, high efficiency, and low manufacturing costs, which align well with the growing demand for sustainable industrial applications. Advances in power electronics and control algorithms are enhancing the performance and torque density of synchronous motors, enabling wider adoption in electric vehicles and renewable energy systems. Future trends indicate significant integration of AI-driven predictive maintenance and smart sensor technologies in both motor types to improve operational reliability and energy efficiency.

Reluctance motor Infographic

libterm.com

libterm.com