Brittle failure occurs when a material fractures suddenly without significant plastic deformation, often under stress conditions that exceed its tensile strength. This type of failure is common in ceramics, glass, and some metals at low temperatures, where cracks propagate rapidly and cause sudden breakage. Discover how understanding brittle failure can help you prevent catastrophic damage and improve material performance in your applications.

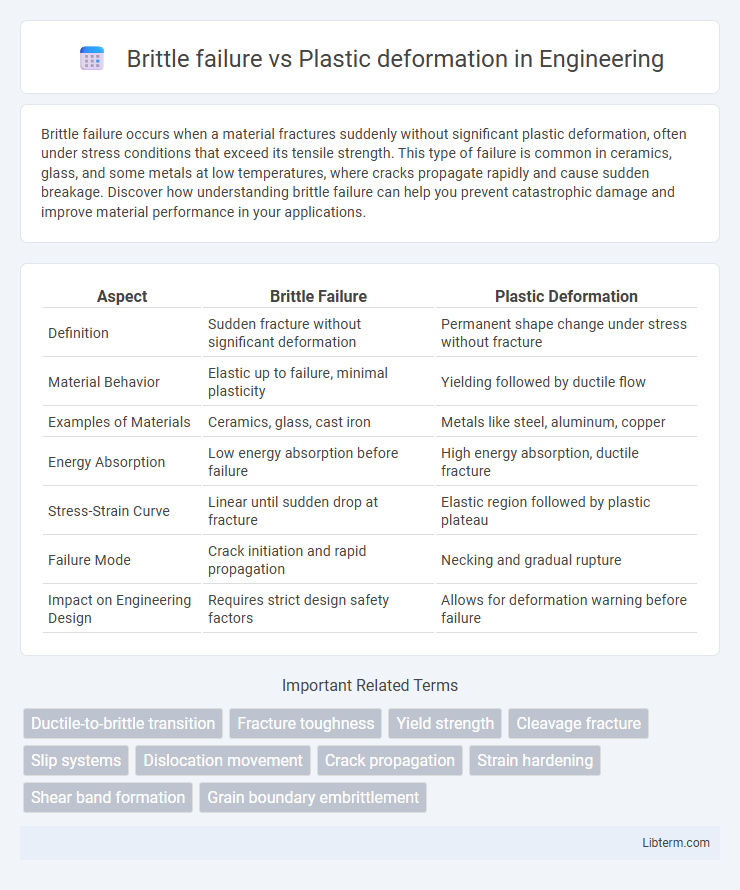

Table of Comparison

| Aspect | Brittle Failure | Plastic Deformation |

|---|---|---|

| Definition | Sudden fracture without significant deformation | Permanent shape change under stress without fracture |

| Material Behavior | Elastic up to failure, minimal plasticity | Yielding followed by ductile flow |

| Examples of Materials | Ceramics, glass, cast iron | Metals like steel, aluminum, copper |

| Energy Absorption | Low energy absorption before failure | High energy absorption, ductile fracture |

| Stress-Strain Curve | Linear until sudden drop at fracture | Elastic region followed by plastic plateau |

| Failure Mode | Crack initiation and rapid propagation | Necking and gradual rupture |

| Impact on Engineering Design | Requires strict design safety factors | Allows for deformation warning before failure |

Introduction to Brittle Failure and Plastic Deformation

Brittle failure occurs when a material fractures suddenly without significant prior deformation, often under tensile stress, due to crack propagation and low energy absorption. Plastic deformation refers to the permanent change in shape or size of a material under applied stress beyond its elastic limit, characterized by dislocation movement and energy dissipation. Understanding the contrast between brittle failure and plastic deformation is critical in materials science for predicting failure modes and designing resilient structures.

Fundamental Concepts and Definitions

Brittle failure occurs when a material fractures suddenly with little to no plastic deformation, characterized by rapid crack propagation and low energy absorption before failure. Plastic deformation involves permanent shape change due to dislocation motion, allowing a material to undergo significant strain without fracturing. The fundamental distinction lies in a material's ability to absorb energy and deform plastically before breaking, with brittle materials showing limited ductility and plastic materials exhibiting higher ductility.

Atomic and Molecular Mechanisms

Brittle failure occurs when atomic bonds break suddenly without significant atomic dislocation, resulting in rapid crack propagation along grain boundaries or cleavage planes. Plastic deformation involves the movement of dislocations through atomic planes, allowing atoms to slip past each other and absorb energy without fracturing. The difference lies in the atomic-scale processes: brittle materials lack sufficient dislocation mobility, causing fracture, while ductile materials enable rearrangement of atomic bonds under stress.

Material Types Prone to Each Behavior

Ceramics and glass are materials prone to brittle failure due to their strong ionic and covalent bonds, which limit dislocation movement and result in sudden fracture without significant plastic deformation. Metals, especially ductile metals like aluminum, copper, and steel, typically exhibit plastic deformation because of their metallic bonding and the ability of dislocations to move and accommodate stress. Polymers can show either behavior; thermoplastics tend to deform plastically under heat, while thermosetting plastics often fail brittly due to their cross-linked molecular structure.

Stress-Strain Characteristics Comparison

Brittle failure is characterized by a sudden fracture with minimal plastic deformation, showing a steep linear stress-strain curve until the point of fracture, indicating low strain tolerance and high strength. Plastic deformation displays a stress-strain curve with an initial linear elastic region followed by a yield point and a significant plastic region where strain increases without a substantial rise in stress. The difference in these stress-strain characteristics reflects brittle materials' inability to absorb energy before failure and plastic materials' capacity for permanent deformation under applied stress.

Factors Influencing Brittle and Plastic Responses

Material composition, temperature, and strain rate critically influence whether a material undergoes brittle failure or plastic deformation. High strain rates and low temperatures promote brittle failure by limiting atomic mobility, causing sudden fracture without significant plastic deformation. Conversely, ductile materials with high temperature exposure and slow strain rates favor plastic deformation, characterized by atomic rearrangement and energy absorption before fracture.

Visual Identification and Fracture Patterns

Brittle failure is visually identified by a clean, sharp fracture surface with minimal plastic deformation, often displaying a granular or crystalline pattern known as cleavage planes. In contrast, plastic deformation shows noticeable necking and elongation before fracture, with fracture surfaces exhibiting ductile features such as dimples or microvoid coalescence. Recognizing these patterns helps determine material behavior under stress and predict failure modes in engineering applications.

Role of Temperature and Loading Rate

Brittle failure typically occurs at low temperatures and high loading rates, where materials exhibit limited plastic deformation due to reduced atomic mobility and rapid stress application. Plastic deformation is favored at higher temperatures and slower loading rates, allowing dislocation movement and energy dissipation before fracture. The transition between these behaviors is critical in materials like steel, where the ductile-to-brittle transition temperature defines safe operational limits under varying mechanical stress conditions.

Engineering Applications and Case Studies

Brittle failure in engineering materials such as ceramics and high-strength steel often leads to sudden fracture without significant deformation, posing risks in structural applications where load predictability is critical. Plastic deformation, commonly observed in ductile metals like aluminum and copper, allows for energy absorption and shape change before failure, enhancing safety and durability in automotive and aerospace components. Case studies in civil engineering highlight how bridges with ductile steel reinforcements withstand overload through plastic deformation, while brittle failure in concrete under tensile stress necessitates careful design to prevent catastrophic collapse.

Strategies for Mitigating Undesirable Failure

Implementing proper material selection and heat treatment enhances resistance to brittle failure by increasing toughness and reducing susceptibility to crack initiation. Applying surface treatments such as shot peening or carburizing improves fatigue resistance, thereby promoting plastic deformation before fracture. Design modifications including stress concentration reduction and incorporating ductile materials help control strain localization and delay crack propagation, effectively mitigating undesirable failure modes.

Brittle failure Infographic

libterm.com

libterm.com