Fixed form refers to a specific, unchanging shape or configuration that remains consistent in various contexts, especially in design or technical applications. This concept ensures precision and uniformity, making it crucial for accurate reproduction and functionality. Explore the rest of this article to understand how fixed form impacts your projects and industry standards.

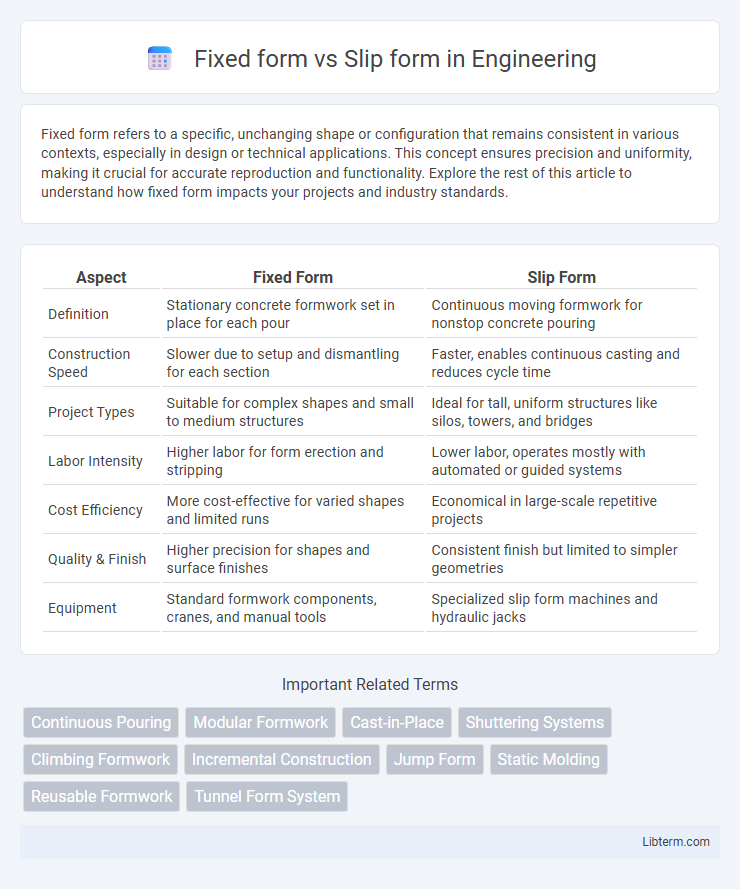

Table of Comparison

| Aspect | Fixed Form | Slip Form |

|---|---|---|

| Definition | Stationary concrete formwork set in place for each pour | Continuous moving formwork for nonstop concrete pouring |

| Construction Speed | Slower due to setup and dismantling for each section | Faster, enables continuous casting and reduces cycle time |

| Project Types | Suitable for complex shapes and small to medium structures | Ideal for tall, uniform structures like silos, towers, and bridges |

| Labor Intensity | Higher labor for form erection and stripping | Lower labor, operates mostly with automated or guided systems |

| Cost Efficiency | More cost-effective for varied shapes and limited runs | Economical in large-scale repetitive projects |

| Quality & Finish | Higher precision for shapes and surface finishes | Consistent finish but limited to simpler geometries |

| Equipment | Standard formwork components, cranes, and manual tools | Specialized slip form machines and hydraulic jacks |

Introduction to Concrete Formwork Methods

Fixed formwork involves assembling rigid, reusable molds to shape concrete, providing precise dimensions and smooth finishes ideal for repetitive construction tasks. Slip formwork employs a continuously moving form that gradually rises as concrete is poured, optimizing efficiency for tall structures like silos and towers. Both methods significantly influence construction speed, material usage, and structural integrity in concrete projects.

Overview of Fixed Form Technique

The Fixed Form technique in concrete construction involves using reusable, rigid molds to shape and support the material until it hardens, providing precise control over dimensions and surface finishes. This method is ideal for structures requiring complex shapes or architectural details, as the forms can be custom-fabricated from materials such as steel, wood, or aluminum. Fixed forms enhance durability and quality by minimizing material deformation during curing, making them suitable for high-rise buildings, bridges, and precast panels.

Fundamentals of Slip Forming

Slip forming is a continuous concrete pouring technique where formwork moves steadily, enabling uninterrupted construction of vertical structures like silos and towers. Unlike fixed form methods that require sequential setting and dismantling, slip forming enhances efficiency by maintaining constant concrete placement and vibration. This process relies on synchronized form movement and concrete rheology control to ensure structural integrity and surface finish quality.

Key Differences: Fixed Form vs Slip Form

Fixed form construction involves setting up stationary molds that are reused for each section of a concrete structure, ensuring precise shapes and high-quality finishes but requiring more time and labor. Slip form uses continuously moving forms that slip upward as concrete is poured, allowing for faster construction of tall, vertical structures like silos, towers, and bridges. The key differences lie in speed, flexibility, and surface finish, with fixed form favoring detailed finishes and slip form optimizing efficiency for large-scale, continuous pours.

Material and Equipment Requirements

Fixed form construction demands precise, reusable molds made from steel or heavy timber, requiring extensive bracing and support equipment to maintain shape during curing. Slip form technique utilizes continuous formwork systems propelled slowly by hydraulic jacks, minimizing the need for multiple molds and allowing a steady flow of concrete placement and reinforcement installation. Material requirements for slip form emphasize high-performance concrete with quick setting properties, while fixed form projects can accommodate a wider range of mixes due to the longer curing time within rigid forms.

Construction Speed and Efficiency

Slip form construction significantly accelerates the building process by allowing continuous concrete pouring without formwork removal, enhancing overall project efficiency. Fixed form methods require setting, curing, and dismantling forms in sequential stages, which extends construction time and labor costs. Slip form's ability to maintain a steady workflow reduces downtime and labor intensity, making it ideal for large-scale infrastructure projects demanding rapid completion.

Quality and Surface Finishing Comparisons

Fixed form concrete construction typically yields superior surface quality due to the rigidity and stability of the molds, allowing for precise shaping and smooth finishes. Slip form techniques, while efficient for continuous pours, may result in variable surface textures and increased risk of minor defects because of the moving formwork. Quality control is generally more consistent with fixed forms, making them preferable for projects demanding high aesthetic and structural surface standards.

Cost Implications and Budget Considerations

Fixed form construction typically involves higher upfront costs due to the need for custom molds and labor-intensive setup, making it less flexible but more precise for smaller projects or intricate designs. Slip form construction offers cost efficiency on large-scale projects, as continuous pouring reduces labor time and formwork expenses, optimizing budget allocation for long, repetitive structures like highways or silos. Budget considerations should weigh project size, timeline, and complexity to determine the most economical choice between the fixed form's higher initial investment and slip form's operational savings.

Suitable Applications for Each Method

Fixed form construction is ideal for small to medium-sized projects requiring precise, uniform concrete shapes such as walls, beams, and columns in residential buildings or detailed architectural features. Slip form is best suited for large-scale, continuous structures like tall silos, chimneys, or bridges where rapid, uninterrupted vertical or horizontal concrete placement is needed. Both methods optimize construction efficiency but are chosen based on project scale, complexity, and speed requirements.

Choosing the Right Formwork for Your Project

Selecting the appropriate formwork between fixed form and slip form depends on project scale, speed requirements, and structural complexity. Fixed formwork offers stability and precision for smaller, repetitive tasks such as columns or walls, while slip form is ideal for continuous, high-rise structures, enabling faster progress with minimal joint lines. Evaluating factors like material reuse, labor intensity, and desired finish quality ensures optimal formwork choice, enhancing overall construction efficiency and safety.

Fixed form Infographic

libterm.com

libterm.com