Surface waviness refers to the repetitive, closely spaced deviations on a surface that occur at a larger scale than surface roughness but smaller than form errors. It significantly impacts the performance and appearance of mechanical parts by affecting factors such as friction, wear, and sealing capabilities. Discover how understanding surface waviness can improve your manufacturing precision and product quality by reading the rest of this article.

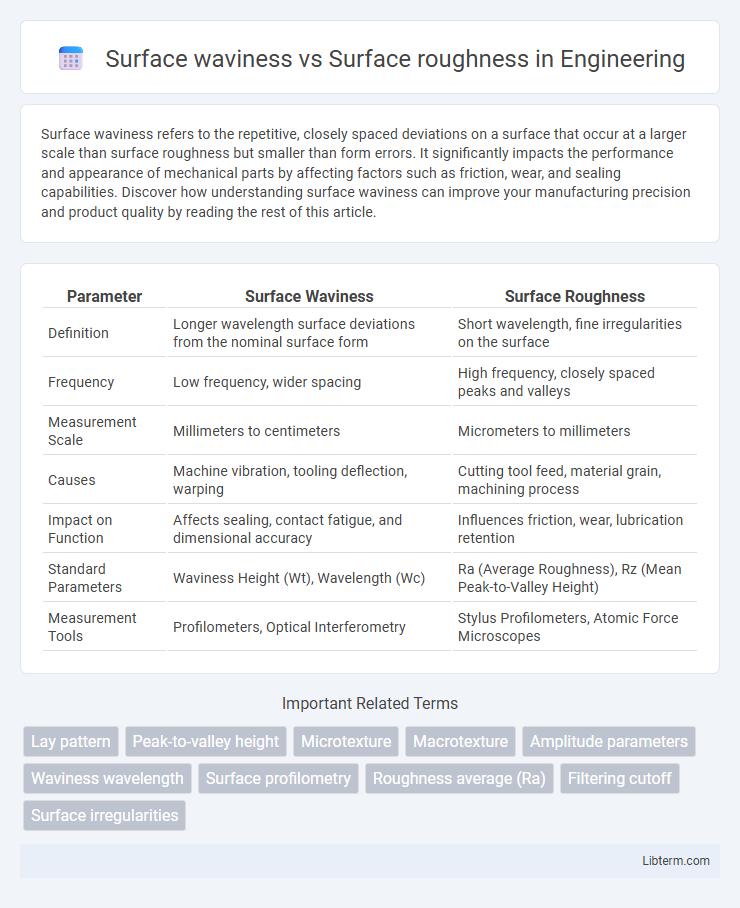

Table of Comparison

| Parameter | Surface Waviness | Surface Roughness |

|---|---|---|

| Definition | Longer wavelength surface deviations from the nominal surface form | Short wavelength, fine irregularities on the surface |

| Frequency | Low frequency, wider spacing | High frequency, closely spaced peaks and valleys |

| Measurement Scale | Millimeters to centimeters | Micrometers to millimeters |

| Causes | Machine vibration, tooling deflection, warping | Cutting tool feed, material grain, machining process |

| Impact on Function | Affects sealing, contact fatigue, and dimensional accuracy | Influences friction, wear, lubrication retention |

| Standard Parameters | Waviness Height (Wt), Wavelength (Wc) | Ra (Average Roughness), Rz (Mean Peak-to-Valley Height) |

| Measurement Tools | Profilometers, Optical Interferometry | Stylus Profilometers, Atomic Force Microscopes |

Understanding Surface Texture: Waviness vs. Roughness

Surface waviness refers to the broader, more widely spaced deviations on a surface caused by factors like machine vibrations or deflection, while surface roughness consists of the finer, closely spaced irregularities resulting from the material removal process. Understanding the distinction between waviness and roughness is critical for evaluating surface texture since waviness affects functional performance such as sealing and fatigue resistance, whereas roughness primarily influences friction and wear. Precise measurement tools like profilometers differentiate these parameters by filtering out waviness to isolate roughness, enabling optimized manufacturing control and quality assurance.

Defining Surface Waviness in Manufacturing

Surface waviness in manufacturing refers to the more widely spaced deviations of a surface profile, characterized by longer wavelength irregularities caused by factors such as machine tool vibrations or workpiece deflections. It differs from surface roughness, which involves finer, closely spaced surface irregularities arising primarily from the cutting process itself. Accurate measurement and control of surface waviness are crucial for ensuring the functional performance and longevity of precision-engineered components.

What is Surface Roughness?

Surface roughness refers to the fine, closely spaced irregularities on a machined or finished surface, typically measured by parameters such as Ra (average roughness) or Rz (average maximum height). It indicates the texture and quality of a surface at a micro-level, impacting friction, wear, and adhesion properties in engineering applications. Surface waviness, on the other hand, describes larger, more widely spaced deviations from the nominal surface profile caused by factors like machine vibrations or deflections.

Key Differences Between Waviness and Roughness

Surface waviness refers to the more widely spaced, longer-wavelength deviations on a machined surface, while surface roughness describes the finer, short-wavelength irregularities. Waviness is typically caused by factors such as machine vibrations, tool deflections, or workpiece warping, whereas roughness results from the cutting process and tool condition. Measurements of waviness often use larger sampling lengths compared to roughness to distinguish these surface texture components clearly.

Causes of Surface Waviness

Surface waviness originates from mechanical vibrations, tool deflections, and machine tool inaccuracies, which create periodic deviations over longer wavelengths compared to surface roughness. Factors such as improper machine setup, unstable cutting conditions, and worn-out tooling exacerbate waviness formation by inducing fluctuating contact between the tool and workpiece. Unlike surface roughness caused primarily by tool feed and material properties, surface waviness reflects broader imperfections in machining system stability and dynamic behavior.

Common Sources of Surface Roughness

Surface roughness primarily originates from machining processes such as cutting, grinding, and milling, where tool geometry, feed rate, and cutting speed influence the micro-scale texture. Material properties, including hardness and ductility, also affect roughness by altering chip formation and tool wear rates. Surface waviness differs as it reflects macro-scale deviations caused by factors like machine tool vibration, deflections, and improper workpiece setup rather than the inherent machining process parameters.

Measurement Techniques for Waviness

Surface waviness measurement techniques primarily involve stylus profilometry and optical methods such as white light interferometry. Stylus profilometers trace the surface profile to isolate waviness by filtering out smaller roughness components using Gaussian or spline filters. Optical techniques offer non-contact, high-resolution waviness characterization by capturing surface height variations over larger areas, enabling detailed analysis of waviness wavelength and amplitude.

Methods for Measuring Surface Roughness

Surface roughness measurement primarily utilizes profilometers, including contact stylus and non-contact optical systems, which capture fine surface irregularities at a micro-scale level. Atomic force microscopy (AFM) and white light interferometry provide high-resolution data essential for analyzing minute surface features beyond conventional profilometry. These methods enable precise quantification of surface texture parameters such as Ra (average roughness), Rq (root mean square roughness), and Rz (ten-point height), critical for quality control in manufacturing and engineering applications.

Impact of Surface Waviness and Roughness on Performance

Surface waviness influences the overall contact behavior and load distribution of a material, affecting sealing effectiveness and fatigue life in mechanical components. Surface roughness primarily impacts friction, wear, and lubrication retention, directly altering operational efficiency and component lifespan. Both characteristics together determine the durability, noise generation, and corrosion resistance of engineered surfaces in industrial applications.

Industry Standards for Surface Texture Analysis

Surface waviness and surface roughness are critical parameters in industry standards for surface texture analysis, such as ISO 4287 and ASME B46.1, which define measurement techniques and cutoff lengths to differentiate these components. Surface waviness refers to the more widely spaced deviations often caused by machine or workpiece deflections, while surface roughness captures finer irregularities from the manufacturing process. Accurate assessment following these standards ensures product functionality and quality in sectors like aerospace, automotive, and precision engineering.

Surface waviness Infographic

libterm.com

libterm.com