Closed feedback systems restrict information flow to specific participants, enhancing confidentiality and focused communication. This approach fosters a secure environment for honest critique, promoting targeted improvements within teams or projects. Explore the rest of the article to understand how closed feedback can transform your organizational dynamics.

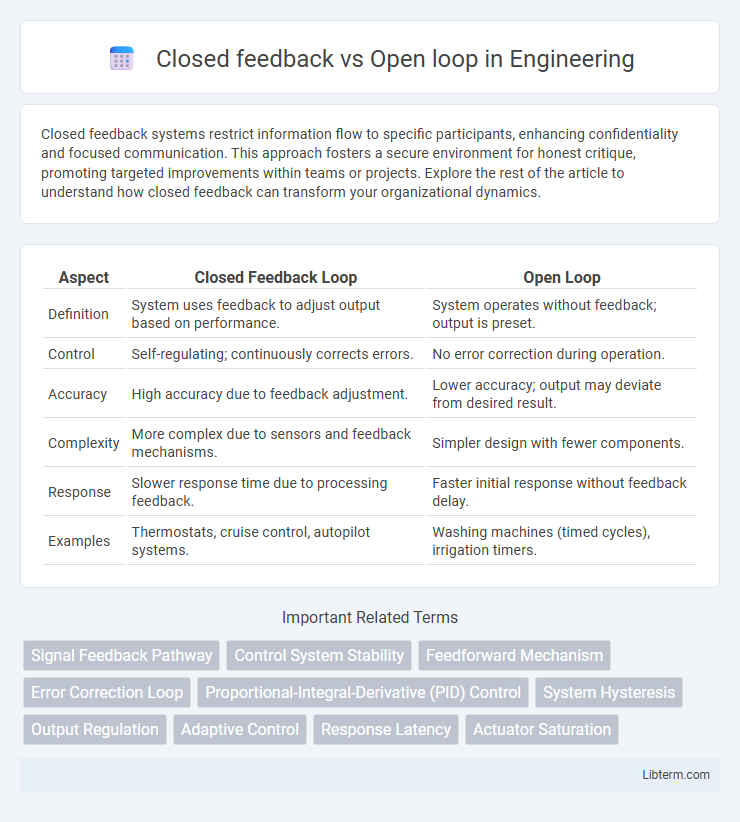

Table of Comparison

| Aspect | Closed Feedback Loop | Open Loop |

|---|---|---|

| Definition | System uses feedback to adjust output based on performance. | System operates without feedback; output is preset. |

| Control | Self-regulating; continuously corrects errors. | No error correction during operation. |

| Accuracy | High accuracy due to feedback adjustment. | Lower accuracy; output may deviate from desired result. |

| Complexity | More complex due to sensors and feedback mechanisms. | Simpler design with fewer components. |

| Response | Slower response time due to processing feedback. | Faster initial response without feedback delay. |

| Examples | Thermostats, cruise control, autopilot systems. | Washing machines (timed cycles), irrigation timers. |

Introduction to Feedback Mechanisms

Feedback mechanisms in control systems operate through closed feedback loops, where the output is continuously monitored and adjusted to achieve desired performance, or open loops, which function without real-time output monitoring. Closed feedback loops enhance system stability and accuracy by using sensors and controllers to correct deviations, essential in applications like automatic temperature control and robotics. Open loop systems rely on predefined inputs without corrective feedback, suitable for simpler, predictable tasks like basic timers or washing machines without load sensors.

What is Closed Feedback?

Closed feedback refers to a control system mechanism where the output is continuously monitored and compared to the input or desired setpoint to automatically adjust the process for maintaining stability and accuracy. This loop enables real-time correction by feeding the measured output back into the controller, minimizing errors and enhancing performance in systems such as thermostats, autopilots, and industrial automation. Closed feedback systems provide higher precision and adaptability compared to open loop systems, which lack this self-correcting feature.

What is Open Loop Feedback?

Open loop feedback refers to a control system where the output is not measured or fed back into the system for adjustment, relying solely on pre-set inputs or commands. This type of feedback system operates without real-time monitoring, making it less adaptive to changes or external disturbances compared to closed loop systems. Open loop feedback is commonly used in simple applications where precision and error correction are not critical.

Key Differences Between Closed and Open Loop

Closed loop systems use feedback to continuously adjust output based on real-time data, ensuring precise control and stability. Open loop systems operate without feedback, relying solely on initial input commands, which can lead to inaccuracies under varying conditions. The key difference lies in the presence of feedback mechanisms that enable closed loops to self-correct, while open loops function with fixed control actions.

Advantages of Closed Feedback Systems

Closed feedback systems provide precise control by continuously monitoring output and making real-time adjustments, reducing errors and improving stability in processes. These systems enhance efficiency in applications such as robotics, HVAC, and automated manufacturing by maintaining desired performance despite external disturbances. The ability to self-correct minimizes manual intervention and optimizes system reliability over open loop configurations.

Advantages of Open Loop Systems

Open loop systems offer simplicity and cost-effectiveness by eliminating the need for feedback sensors, reducing complexity and maintenance requirements. They provide faster response times in applications where system dynamics are predictable and external disturbances are minimal. Open loop designs enable straightforward implementation in automated processes with consistent input-output relationships, enhancing reliability and ease of control.

Applications of Closed Feedback

Closed feedback systems are widely applied in industrial automation for precise control of machinery and process variables, enhancing efficiency and accuracy. In robotics, closed feedback enables real-time adjustments to maintain desired motion trajectories and respond to environmental changes. HVAC systems use closed feedback loops to regulate temperature and airflow, ensuring optimal climate control and energy savings.

Applications of Open Loop

Open loop control systems are widely applied in simple household appliances such as washing machines and microwave ovens, where the operation follows predetermined instructions without feedback adjustments. These systems also enable precise control in industrial processes like conveyor belts and irrigation systems, where the environment remains stable and predictable. Their efficiency lies in cost-effectiveness and ease of implementation when real-time feedback is unnecessary or impractical.

Challenges and Limitations

Closed feedback systems face challenges in adaptability due to their reliance on fixed response mechanisms, limiting performance in dynamic environments. Open loop systems lack real-time error correction, resulting in potential inaccuracies and decreased reliability under changing conditions. Both systems encounter limitations in handling unpredictable variables, but closed feedback is constrained by slower response times while open loop struggles with precision.

Which Feedback System is Right for You?

Closed feedback systems provide continuous monitoring and automatic adjustments based on real-time data, making them ideal for applications requiring high precision and stability, such as robotics or process control. Open loop systems operate without feedback, using predefined inputs, which suits simpler tasks where environmental conditions are predictable and cost-effectiveness is a priority. Choosing the right feedback system depends on factors like accuracy requirements, system complexity, and budget constraints, with closed loop favored for dynamic environments and open loop for straightforward, low-cost operations.

Closed feedback Infographic

libterm.com

libterm.com