Elastic deformation occurs when a material undergoes a temporary change in shape or size under stress but returns to its original form once the stress is removed. This phenomenon is critical in designing structures and materials that need to withstand forces without permanent damage. Discover how understanding elastic deformation can enhance Your knowledge of material behavior by reading the rest of the article.

Table of Comparison

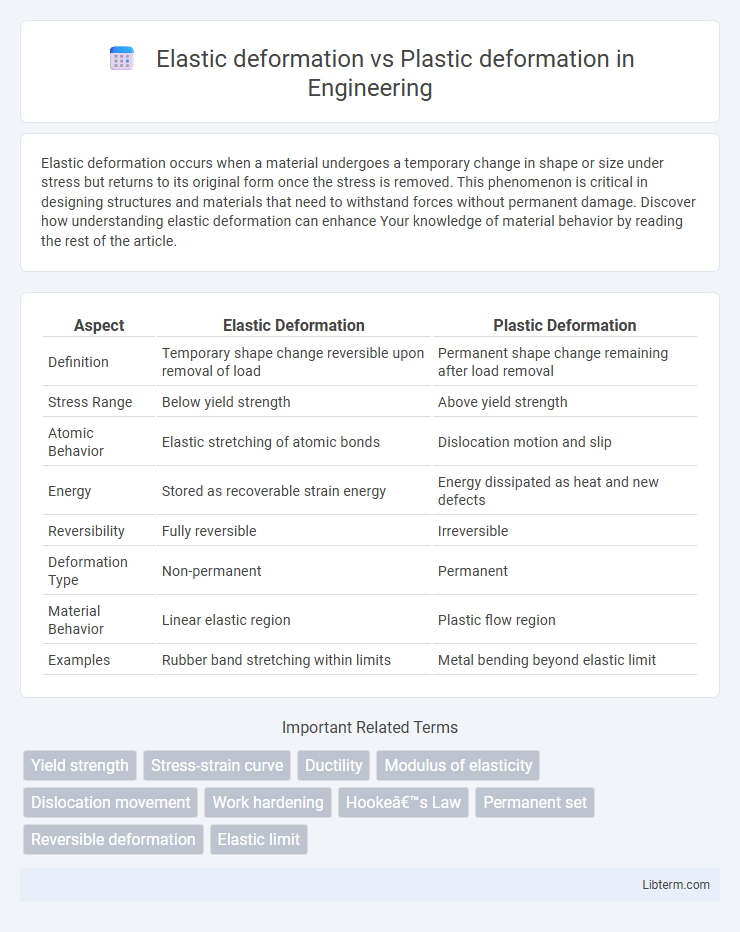

| Aspect | Elastic Deformation | Plastic Deformation |

|---|---|---|

| Definition | Temporary shape change reversible upon removal of load | Permanent shape change remaining after load removal |

| Stress Range | Below yield strength | Above yield strength |

| Atomic Behavior | Elastic stretching of atomic bonds | Dislocation motion and slip |

| Energy | Stored as recoverable strain energy | Energy dissipated as heat and new defects |

| Reversibility | Fully reversible | Irreversible |

| Deformation Type | Non-permanent | Permanent |

| Material Behavior | Linear elastic region | Plastic flow region |

| Examples | Rubber band stretching within limits | Metal bending beyond elastic limit |

Introduction to Material Deformation

Material deformation occurs when external forces cause a change in shape or size of a material. Elastic deformation is a reversible change where the material returns to its original form after the stress is removed, governed by Hooke's Law and characterized by the elastic modulus. Plastic deformation involves permanent structural changes beyond the yield point, resulting from dislocation movement and slip, and is critical in understanding material strength and ductility.

Defining Elastic Deformation

Elastic deformation is the reversible change in shape or size of a material when subjected to stress, where the material returns to its original form upon release of the applied force. This behavior occurs within the material's elastic limit, characterized by the proportionality between stress and strain described by Hooke's Law. Elastic deformation is critical in engineering applications requiring materials to withstand temporary forces without permanent damage.

Explaining Plastic Deformation

Plastic deformation occurs when a material undergoes a permanent change in shape or size due to stress exceeding its yield strength, causing dislocation movement within the crystal structure. Unlike elastic deformation, which is reversible, plastic deformation results in irreversible microstructural alterations and energy dissipation. This phenomenon is critical in metal forming processes such as forging, rolling, and extrusion, where control of material flow and shape retention is essential.

Key Differences: Elastic vs Plastic Deformation

Elastic deformation is reversible, occurring when a material changes shape under stress but returns to its original form once the stress is removed, typically observed within the material's elastic limit. Plastic deformation results in a permanent shape change due to atomic or molecular dislocation beyond the yield strength, causing irreversible structural rearrangements. Key differences include elasticity being temporary and non-destructive, while plastic deformation causes permanent, permanent structural changes in materials like metals and polymers.

Atomic and Molecular Mechanisms

Elastic deformation occurs when atomic bonds within a material's lattice structure stretch but do not break, allowing atoms to return to their original positions once the stress is removed. Plastic deformation involves the movement and rearrangement of dislocations at the atomic level, causing permanent shifts in the molecular structure and irreversible changes in shape. The difference lies in elastic deformation preserving atomic integrity, while plastic deformation results from atomic slip and dislocation motion that alters the material's microstructure.

Factors Affecting Deformation Behavior

Material composition, temperature, and applied stress significantly influence elastic and plastic deformation behaviors. High temperatures typically reduce yield strength, promoting plastic deformation, while low temperatures favor elastic responses. Microstructural characteristics such as grain size and dislocation density also determine the extent and type of deformation exhibited by metals and polymers.

Stress-Strain Curve Analysis

Elastic deformation occurs when a material returns to its original shape after the applied stress is removed, represented by the initial linear portion of the stress-strain curve, where stress is proportional to strain according to Hooke's Law. Plastic deformation begins at the yield point on the stress-strain curve, where permanent deformation occurs, and the material no longer returns to its original shape, marked by a nonlinear curve beyond the elastic limit. Stress-strain curve analysis reveals critical mechanical properties such as the modulus of elasticity, yield strength, and ultimate tensile strength, essential for understanding material behavior under load.

Real-World Examples and Applications

Elastic deformation occurs in materials like rubber bands and springs, which return to their original shape after stress is removed, essential in applications such as automotive suspension systems and flexible electronics. Plastic deformation involves permanent shape change, seen in metal forging, machining, and structural components under high stress, crucial for manufacturing processes like car body shaping and bridge construction. Understanding these deformation types enables engineers to select appropriate materials and design structures that balance flexibility and durability in various real-world applications.

Implications for Material Selection

Elastic deformation is reversible and occurs when materials are subjected to stress within their elastic limit, making materials with high elasticity ideal for applications requiring flexibility and energy absorption, such as springs and shock absorbers. Plastic deformation is permanent and occurs after the yield point, which is critical for materials used in forming processes like metal stamping or structural components that must maintain shape under load. Selecting materials hinges on balancing elasticity for temporary shape changes against plasticity for permanent deformation, ensuring performance and durability in specific engineering applications.

Future Trends in Deformation Research

Future trends in deformation research emphasize advanced characterization techniques using in-situ electron microscopy and synchrotron radiation to distinguish microscopic elastic and plastic behaviors with unprecedented resolution. Machine learning models are increasingly applied to predict the transition thresholds and deformation mechanisms in novel materials, enhancing the design of alloys with tailored mechanical properties. Nanotechnology integration aims to manipulate deformation at atomic scales, enabling the development of smart materials that can recover from plastic deformation or adapt their stiffness dynamically.

Elastic deformation Infographic

libterm.com

libterm.com