Labyrinth seals provide an efficient, non-contact method to prevent leakage of fluids and contaminants in rotating machinery by using intricate interlocking pathways that create multiple flow restrictions. They are widely used in turbines, compressors, and pumps to enhance performance and reduce wear without direct surface contact. Discover how labyrinth seals can improve your equipment's reliability and longevity by exploring the detailed advantages and applications in the rest of this article.

Table of Comparison

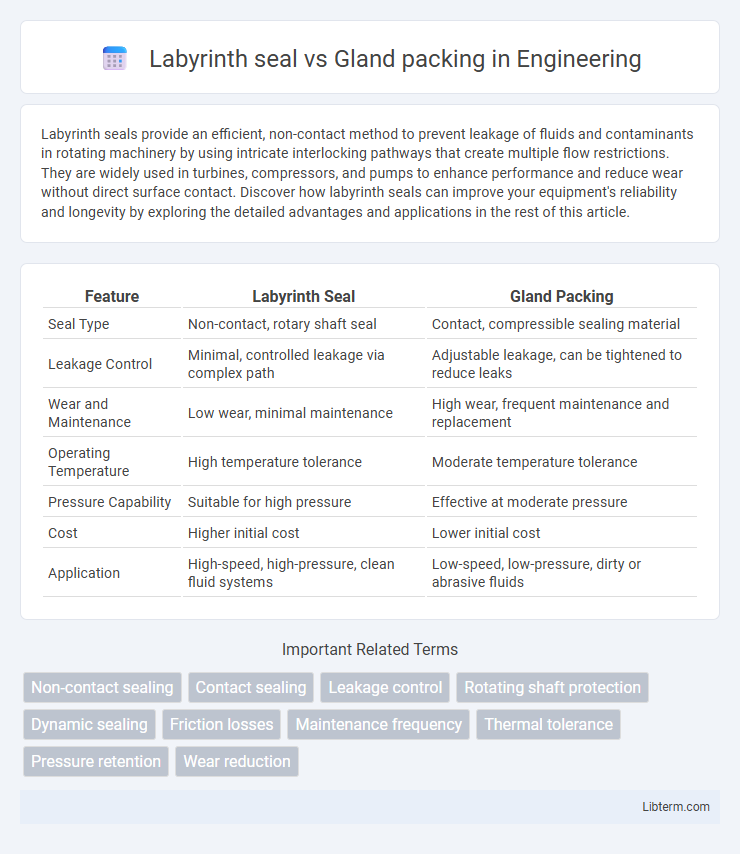

| Feature | Labyrinth Seal | Gland Packing |

|---|---|---|

| Seal Type | Non-contact, rotary shaft seal | Contact, compressible sealing material |

| Leakage Control | Minimal, controlled leakage via complex path | Adjustable leakage, can be tightened to reduce leaks |

| Wear and Maintenance | Low wear, minimal maintenance | High wear, frequent maintenance and replacement |

| Operating Temperature | High temperature tolerance | Moderate temperature tolerance |

| Pressure Capability | Suitable for high pressure | Effective at moderate pressure |

| Cost | Higher initial cost | Lower initial cost |

| Application | High-speed, high-pressure, clean fluid systems | Low-speed, low-pressure, dirty or abrasive fluids |

Introduction to Labyrinth Seal and Gland Packing

Labyrinth seals use a series of interlocking ridges to create a complex path that minimizes fluid leakage and contamination, ideal for high-speed rotating equipment. Gland packing involves compressible fibers packed tightly around a shaft to prevent leakage in pumps and valves, offering simpler installation and maintenance. Both sealing methods serve critical roles in controlling fluid flow and protecting machinery components under varying operational conditions.

Basic Principles and Working Mechanisms

Labyrinth seals prevent fluid leakage by creating a complex path that disrupts fluid flow using interlocking ridges, which increases resistance and reduces pressure. Gland packing operates by compressing flexible material around the shaft to form a tight seal, preventing leakage through static and dynamic pressure containment. The fundamental difference lies in labyrinth seals relying on tortuous fluid paths without contact, while gland packing achieves sealing through mechanical compression and friction.

Key Differences in Functionality

Labyrinth seals create a complex path that prevents fluid leakage through intricate grooves and air gaps, relying on turbulence and pressure drops for sealing efficiency, making them ideal for high-speed rotating shafts. Gland packing, by contrast, uses compressible material tightly packed around the shaft to provide a mechanical barrier against leaks, suitable for moderate speeds and requiring regular maintenance for optimal performance. The primary functional difference lies in labyrinth seals' non-contact design minimizing wear, whereas gland packing depends on contact and friction, impacting durability and maintenance needs.

Applications in Various Industries

Labyrinth seals excel in high-speed rotating equipment such as turbines, compressors, and pumps due to their non-contact design that minimizes wear and maintenance. Gland packing is widely used in industries like petrochemical, marine, and power generation for sealing valves and pumps where moderate leakage is acceptable and cost-effectiveness is critical. The choice between labyrinth seals and gland packing depends on operational conditions, with labyrinth seals favored for high-pressure, high-temperature environments and gland packing preferred for simpler, lower-pressure applications.

Installation and Maintenance Requirements

Labyrinth seals require precise alignment and careful installation to ensure proper functioning, with minimal contact and wear during operation, leading to lower maintenance demands. In contrast, gland packing involves manual adjustment and periodic tightening to maintain a seal, resulting in frequent maintenance checks and potential downtime for re-packing. Labyrinth seals offer a more durable, low-maintenance solution, while gland packing demands ongoing attention to prevent leakage and wear.

Performance in High-Pressure and High-Temperature Environments

Labyrinth seals offer superior performance in high-pressure and high-temperature environments by providing non-contact sealing that reduces wear and extends operational life. Gland packing, while more cost-effective, tends to suffer from accelerated degradation and leakage under extreme conditions due to its friction-based sealing mechanism. The choice between labyrinth seals and gland packing depends on balancing durability, maintenance frequency, and upfront costs in demanding industrial applications.

Leakage Control and Fluid Containment

Labyrinth seals offer superior leakage control by creating a tortuous path that minimizes fluid escape without direct contact, reducing wear and maintenance needs. Gland packing relies on compressible material tightly packed around the shaft, which can lead to gradual leakage and requires frequent adjustment to maintain effective fluid containment. Labyrinth seals excel in high-speed, high-pressure environments by providing non-contact sealing that enhances fluid containment efficiency compared to the friction-based sealing of gland packing.

Cost Comparison and Economic Considerations

Labyrinth seals typically have higher upfront costs due to complex design and precision manufacturing but offer lower maintenance expenses and longer service life compared to gland packing. Gland packing is initially less expensive and simpler to install, but incurs frequent replacement and potential leakage-related costs, increasing total operating expenses. Evaluating lifecycle costs reveals labyrinth seals provide better economic value in applications demanding reliability and minimal downtime.

Durability and Lifespan Analysis

Labyrinth seals offer superior durability compared to gland packing due to their non-contact design, which reduces wear and extends operational lifespan significantly. Gland packing experiences faster degradation from friction and requires frequent maintenance, limiting overall service life. Industrial data shows labyrinth seals can operate efficiently for several years without replacement, whereas gland packing often needs periodic adjustment or replacement within months.

Choosing the Right Seal for Your Application

Choosing the right seal for your application depends on factors such as pressure, temperature, and leakage tolerance. Labyrinth seals offer non-contact sealing ideal for high-speed rotating equipment with minimal leakage and low maintenance, while gland packing provides a cost-effective solution for moderate-pressure environments but requires regular adjustment and can cause higher friction. Evaluate operational conditions, maintenance capabilities, and sealing performance requirements to select between the reliable, long-lasting labyrinth seal and the flexible, low-cost gland packing.

Labyrinth seal Infographic

libterm.com

libterm.com