Orthogonal cutting is a fundamental machining process where the cutting edge of the tool is perpendicular to the direction of the cutting velocity, resulting in a simplified analysis of forces and chip formation. Understanding this process is essential for optimizing tool performance, surface finish, and material removal rates in manufacturing. Discover more about how orthogonal cutting can enhance your machining operations in the rest of this article.

Table of Comparison

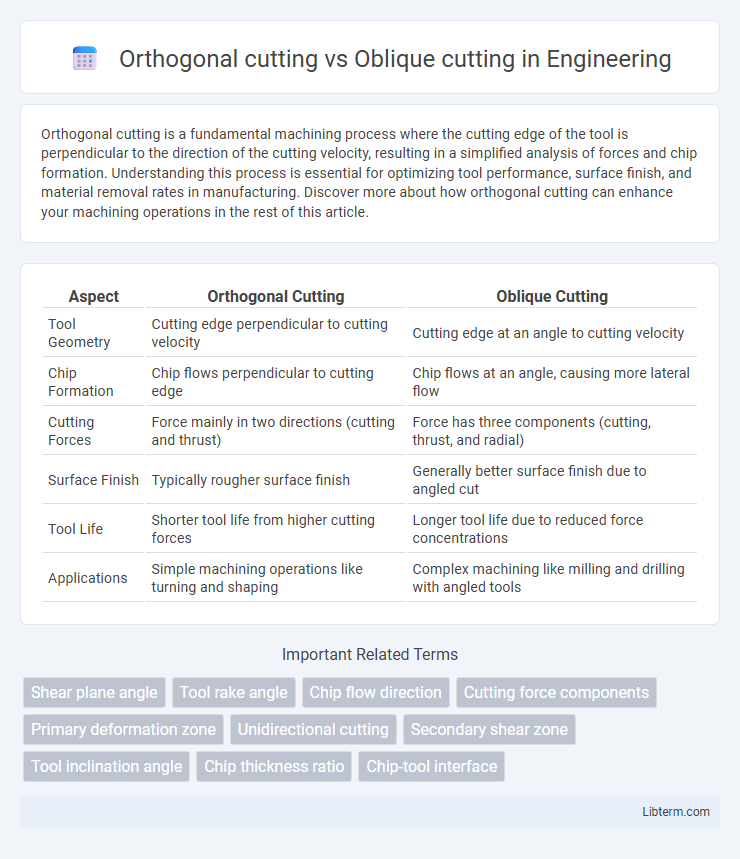

| Aspect | Orthogonal Cutting | Oblique Cutting |

|---|---|---|

| Tool Geometry | Cutting edge perpendicular to cutting velocity | Cutting edge at an angle to cutting velocity |

| Chip Formation | Chip flows perpendicular to cutting edge | Chip flows at an angle, causing more lateral flow |

| Cutting Forces | Force mainly in two directions (cutting and thrust) | Force has three components (cutting, thrust, and radial) |

| Surface Finish | Typically rougher surface finish | Generally better surface finish due to angled cut |

| Tool Life | Shorter tool life from higher cutting forces | Longer tool life due to reduced force concentrations |

| Applications | Simple machining operations like turning and shaping | Complex machining like milling and drilling with angled tools |

Introduction to Orthogonal and Oblique Cutting

Orthogonal cutting involves a cutting edge perpendicular to the cutting velocity direction, resulting in a two-dimensional cutting process with simpler stress and chip formation patterns. Oblique cutting features a cutting edge angled relative to the cutting velocity, creating a three-dimensional cutting process that influences chip flow, cutting forces, and tool wear differently. Understanding the distinctions between orthogonal and oblique cutting is critical for optimizing machining operations, tool design, and surface finish quality.

Definition of Orthogonal Cutting

Orthogonal cutting is a machining process where the cutting edge of the tool is perpendicular to the direction of the cutting velocity, resulting in a two-dimensional cutting action. This method produces a linear shear zone, simplifying the analysis of cutting forces, chip formation, and heat generation. Orthogonal cutting contrasts with oblique cutting, where the tool edge intersects the workpiece at an angle, leading to a more complex, three-dimensional cutting geometry.

Definition of Oblique Cutting

Oblique cutting is a machining process where the cutting edge of the tool intersects the workpiece at an angle other than 90 degrees, causing the chip to flow diagonally away from the cutting zone. This contrasts with orthogonal cutting, where the tool edge is perpendicular to the workpiece surface, resulting in a straight chip flow. The angled tool orientation in oblique cutting reduces cutting forces and tool wear, improving surface finish and tool life.

Key Differences Between Orthogonal and Oblique Cutting

Orthogonal cutting features a cutting edge perpendicular to the workpiece surface, resulting in a two-dimensional chip flow and simpler force analysis, while oblique cutting involves a cutting edge angled relative to the surface, producing a three-dimensional chip flow and more complex forces. The tool geometry in orthogonal cutting leads to higher shear forces concentrated on one plane, enhancing precision but increasing tool wear; oblique cutting distributes forces over a larger area, reducing cutting forces and improving surface finish. Material removal rates and thermal effects also differ, with orthogonal cutting generating higher temperatures localized at the shear zone compared to the broader heat dissipation in oblique cutting.

Cutting Tool Geometry in Orthogonal vs Oblique Cutting

Orthogonal cutting features a cutting edge perpendicular to the cutting velocity, resulting in a simpler cutting tool geometry with a single cutting edge and uniform chip flow. In contrast, oblique cutting involves a cutting edge angled relative to the cutting direction, requiring complex tool geometries with varying rake and clearance angles to manage chip flow and reduce cutting forces. The distinct cutting tool geometries directly influence chip formation, cutting forces, and surface finish quality in both methods.

Chip Formation Mechanisms

Orthogonal cutting produces a continuous chip formed by shearing along a well-defined shear plane, resulting in simpler stress and strain distributions. Oblique cutting generates a helical chip due to the cutting edge's inclination, causing complex chip flow involving three-dimensional deformation and shear zones. The chip formation in orthogonal cutting is dominated by pure shear, while oblique cutting exhibits a combination of shear and sliding mechanisms.

Force Analysis in Orthogonal and Oblique Cutting

Orthogonal cutting generates cutting force primarily in two components: the main cutting force acting parallel to the cutting velocity and the thrust force perpendicular to the cutting velocity, resulting in simpler force analysis due to the unidirectional chip flow. Oblique cutting involves a third force component caused by the cutting edge inclination angle, leading to a more complex force system with the cutting force, thrust force, and radial force acting in three dimensions. Force analysis in oblique cutting requires decomposition of forces into components aligned with the tool geometry and chip flow direction, reflecting the combined effects of shear and friction on the cutting process.

Surface Finish and Quality Comparison

Orthogonal cutting generally results in a superior surface finish due to the shearing action being confined to one plane, which reduces surface irregularities and improves dimensional accuracy. In contrast, oblique cutting involves a cutting edge set at an angle to the workpiece surface, causing a more complex chip flow and increased friction that can degrade surface quality. The quality of the machined surface in orthogonal cutting tends to be more consistent and predictable, making it preferable for precision applications requiring tight tolerances.

Applications of Orthogonal and Oblique Cutting

Orthogonal cutting is widely applied in machining processes requiring simple, straight cutting actions such as turning, shaping, and milling with single-point tools, offering predictable chip flow and force analysis. Oblique cutting is preferred in complex operations like drilling, milling with multi-point tools, and grinding, where the cutting edge engages the workpiece at an angle, improving surface finish and tool life by spreading cutting forces. Industries like automotive manufacturing rely on orthogonal cutting for easy-to-control operations, while aerospace and precision engineering frequently employ oblique cutting for better control over cutting dynamics and chip evacuation.

Advantages and Limitations of Each Cutting Method

Orthogonal cutting offers precise chip formation and simplified analysis due to its 90-degree cutting edge angle, enhancing predictable tool wear and surface finish. However, it often results in higher cutting forces and limited applicability in complex machining tasks. Oblique cutting reduces cutting forces and improves tool life by distributing cutting action over multiple edges but complicates chip control and requires more complex tool geometry and analysis.

Orthogonal cutting Infographic

libterm.com

libterm.com