Gas metal arc welding (GMAW) is a highly efficient welding process that uses a continuous solid wire electrode and an inert or semi-inert gas to shield the weld from contaminants. This method provides excellent weld quality, faster deposition rates, and versatility across various metals and thicknesses. Discover the key techniques and benefits of GMAW to enhance your welding skills by reading the full article.

Table of Comparison

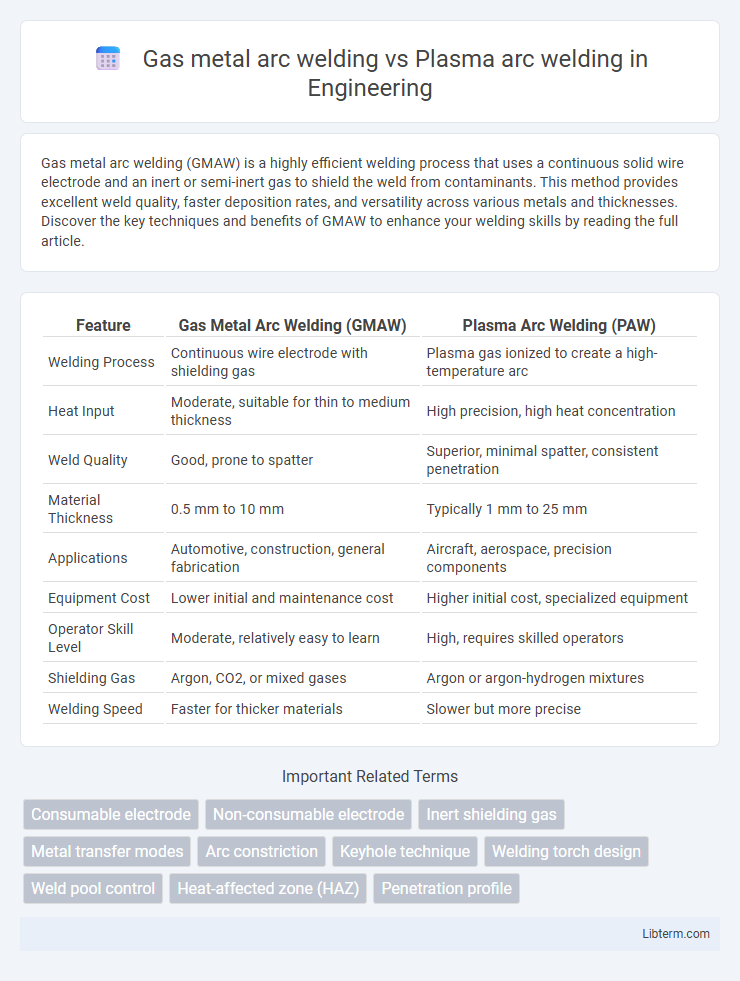

| Feature | Gas Metal Arc Welding (GMAW) | Plasma Arc Welding (PAW) |

|---|---|---|

| Welding Process | Continuous wire electrode with shielding gas | Plasma gas ionized to create a high-temperature arc |

| Heat Input | Moderate, suitable for thin to medium thickness | High precision, high heat concentration |

| Weld Quality | Good, prone to spatter | Superior, minimal spatter, consistent penetration |

| Material Thickness | 0.5 mm to 10 mm | Typically 1 mm to 25 mm |

| Applications | Automotive, construction, general fabrication | Aircraft, aerospace, precision components |

| Equipment Cost | Lower initial and maintenance cost | Higher initial cost, specialized equipment |

| Operator Skill Level | Moderate, relatively easy to learn | High, requires skilled operators |

| Shielding Gas | Argon, CO2, or mixed gases | Argon or argon-hydrogen mixtures |

| Welding Speed | Faster for thicker materials | Slower but more precise |

Overview of Gas Metal Arc Welding (GMAW)

Gas Metal Arc Welding (GMAW), also known as Metal Inert Gas (MIG) welding, uses a continuous solid wire electrode heated and fed into the weld pool from a welding gun. It employs a shielding gas such as argon or CO2 to protect the weld pool from atmospheric contamination, enabling high welding speeds and versatility across various metals including steel, aluminum, and stainless steel. GMAW is widely favored for its ease of automation, efficient deposition rate, and relatively low operator skill requirement compared to other welding processes like Plasma Arc Welding (PAW).

Introduction to Plasma Arc Welding (PAW)

Plasma Arc Welding (PAW) utilizes a high-velocity jet of ionized gas, or plasma, to create a precise and concentrated heat source for welding, enabling superior control over the welding process compared to Gas Metal Arc Welding (GMAW). The plasma arc's temperatures can exceed 20,000degC, producing deeper weld penetration and minimal distortion on metals like stainless steel and aluminum. PAW offers advantages such as higher welding speeds and the ability to weld thin materials with improved consistency, making it ideal for aerospace and electronics industries.

Key Differences Between GMAW and PAW

Gas metal arc welding (GMAW) uses a continuous solid wire electrode to create an electric arc between the wire and the metal workpiece, facilitating rapid and efficient welding primarily suited for thicker materials. Plasma arc welding (PAW) employs a constricted plasma arc through a fine orifice, offering superior control and precision, ideal for welding thin materials and critical joints. Differences include GMAW's higher deposition rates and cost-effectiveness versus PAW's enhanced weld quality, deeper penetration, and ability to weld at higher velocities with minimal distortion.

Applications of Gas Metal Arc Welding

Gas metal arc welding (GMAW) is widely applied in automotive manufacturing, shipbuilding, and structural steel fabrication due to its efficiency and versatility in welding mild steel, stainless steel, and aluminum. It excels in producing high-quality welds on thin to medium-thickness materials with good penetration and minimal spatter, making it ideal for mass production and repair work. GMAW's adaptability to automated and robotic welding systems enhances productivity in diverse industrial applications compared to plasma arc welding, which is often reserved for precision cutting and specialized welding tasks.

Industrial Uses of Plasma Arc Welding

Plasma arc welding (PAW) is highly valued in aerospace, automotive, and medical device manufacturing for its precision and ability to weld thin, sensitive materials with minimal distortion. PAW's concentrated arc and controlled heat input enable superior weld quality on stainless steel, titanium, and nickel alloys often used in high-performance industrial applications. Compared to gas metal arc welding (GMAW), PAW offers enhanced control and cleaner welds essential for critical, high-reliability components in industrial production.

Equipment and Setup Comparison

Gas metal arc welding (GMAW) uses a continuous solid wire electrode fed through a welding gun and requires a shielding gas supply, typically argon or CO2, delivered via a gas cylinder and regulator. Plasma arc welding (PAW) employs a plasma torch with a constricted arc formed between a non-consumable tungsten electrode and the workpiece, necessitating a plasma gas supply and often a secondary shielding gas system. The GMAW setup is generally simpler and more portable, while PAW equipment is more complex, requiring precise control of plasma gas flow, higher amperage power sources, and advanced cooling systems.

Weld Quality and Precision: GMAW vs PAW

Gas Metal Arc Welding (GMAW) offers high deposition rates but generally produces welds with slightly lower precision and potential for spatter compared to Plasma Arc Welding (PAW). PAW achieves superior weld quality and precision due to its focused and stable plasma arc, enabling deeper penetration and finer control, which is ideal for intricate or thin materials. The precise control of heat input in PAW results in minimal distortion and cleaner weld seams, enhancing overall weld integrity and aesthetic finish.

Cost and Efficiency Factors

Gas metal arc welding (GMAW) generally incurs lower operational costs due to simpler equipment and consumables like solid wire electrodes, making it cost-effective for high-volume production. Plasma arc welding (PAW) offers greater efficiency with higher precision and faster welding speeds, reducing rework and material waste despite higher initial investment and maintenance costs. Choosing between GMAW and PAW depends on balancing lower upfront costs with the long-term efficiency gains suited for specific industrial applications.

Safety Considerations in GMAW and PAW

Gas metal arc welding (GMAW) presents safety concerns such as exposure to ultraviolet and infrared radiation, intense heat, and the risk of electric shock, necessitating proper use of personal protective equipment (PPE) including welding helmets with appropriate filter lenses, flame-resistant clothing, and insulated gloves. Plasma arc welding (PAW) generates higher temperatures and more concentrated arcs, increasing the risk of severe burns and arc radiation, requiring stringent ventilation systems to manage harmful fumes and gases, along with PPE specifically designed for high-intensity arcs. Both GMAW and PAW demand rigorous adherence to safety protocols, effective ventilation, and operator training to mitigate hazards commonly associated with welding fumes, radiation, and electrical exposure.

Choosing the Right Method for Your Project

Gas metal arc welding (GMAW) offers efficient, cost-effective welding for thin to medium gauge metals and is ideal for projects requiring high deposition rates and versatility with various materials. Plasma arc welding (PAW) provides superior precision and deeper penetration, making it suitable for intricate, high-quality welds on thicker or highly conductive metals. Selecting the right method depends on factors such as material type, thickness, desired weld quality, and project budget constraints.

Gas metal arc welding Infographic

libterm.com

libterm.com