Heat exchanger effectiveness measures how efficiently heat is transferred between two fluids relative to the maximum possible heat transfer, while the capacity rate ratio compares the heat capacity rates of the fluids involved. A higher effectiveness indicates better performance, and the capacity rate ratio helps determine the limiting fluid and overall heat exchange efficiency. Explore the rest of the article to understand how these concepts impact the design and operation of your heat exchanger system.

Table of Comparison

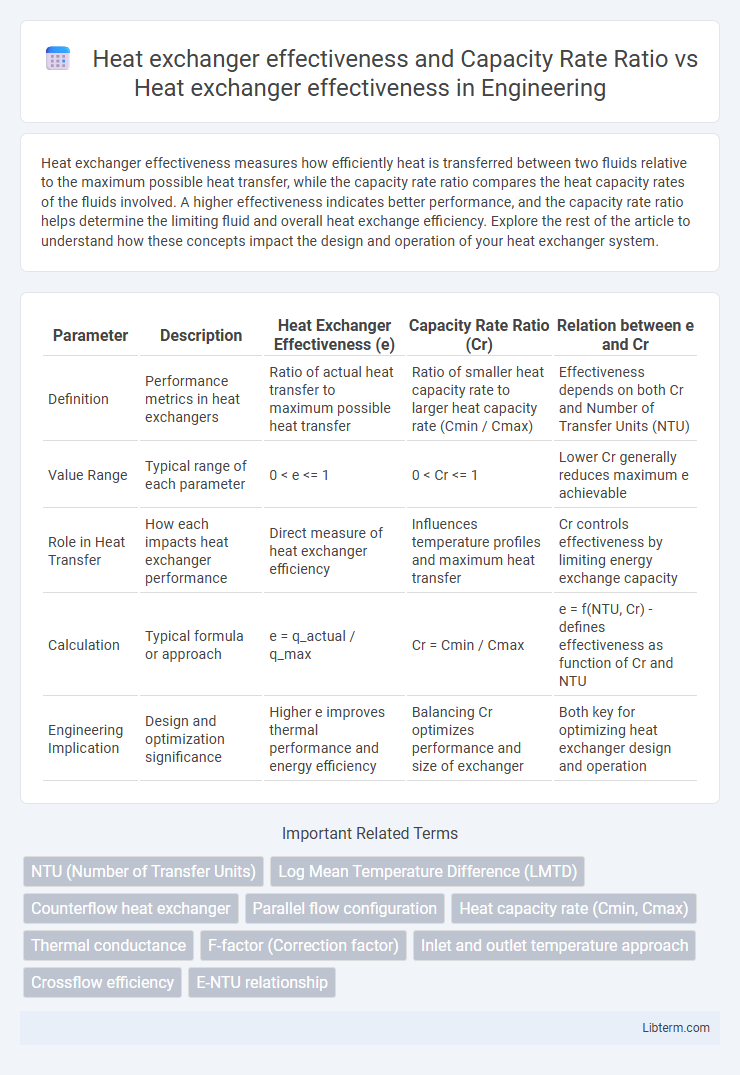

| Parameter | Description | Heat Exchanger Effectiveness (e) | Capacity Rate Ratio (Cr) | Relation between e and Cr |

|---|---|---|---|---|

| Definition | Performance metrics in heat exchangers | Ratio of actual heat transfer to maximum possible heat transfer | Ratio of smaller heat capacity rate to larger heat capacity rate (Cmin / Cmax) | Effectiveness depends on both Cr and Number of Transfer Units (NTU) |

| Value Range | Typical range of each parameter | 0 < e <= 1 | 0 < Cr <= 1 | Lower Cr generally reduces maximum e achievable |

| Role in Heat Transfer | How each impacts heat exchanger performance | Direct measure of heat exchanger efficiency | Influences temperature profiles and maximum heat transfer | Cr controls effectiveness by limiting energy exchange capacity |

| Calculation | Typical formula or approach | e = q_actual / q_max | Cr = Cmin / Cmax | e = f(NTU, Cr) - defines effectiveness as function of Cr and NTU |

| Engineering Implication | Design and optimization significance | Higher e improves thermal performance and energy efficiency | Balancing Cr optimizes performance and size of exchanger | Both key for optimizing heat exchanger design and operation |

Understanding Heat Exchanger Effectiveness

Heat exchanger effectiveness measures the efficiency of heat transfer between hot and cold fluids relative to the maximum possible heat transfer. The Capacity Rate Ratio, defined as the ratio of the smaller to the larger heat capacity rates of the two streams, strongly influences effectiveness, as effectiveness typically decreases with higher ratios approaching unity. Understanding the relationship between heat exchanger effectiveness and capacity rate ratio is critical for optimizing thermal performance and selecting appropriate exchanger types like counterflow, parallel flow, or crossflow configurations.

Defining Capacity Rate Ratio in Heat Exchangers

Capacity Rate Ratio in heat exchangers is defined as the ratio of the minimum heat capacity rate to the maximum heat capacity rate between the hot and cold fluid streams, symbolized as C_r = C_min / C_max. This dimensionless parameter directly influences the heat exchanger effectiveness, which measures the actual heat transfer relative to the maximum possible heat transfer. Understanding the Capacity Rate Ratio is essential for accurately predicting heat exchanger performance and optimizing thermal efficiency in various industrial applications.

Relationship Between Effectiveness and Capacity Rate Ratio

Heat exchanger effectiveness measures the performance of a heat exchanger by comparing the actual heat transfer to the maximum possible heat transfer. The capacity rate ratio, defined as the ratio of the smaller to the larger heat capacity rates of the two fluid streams, directly influences effectiveness by determining the potential for heat transfer between fluids. As the capacity rate ratio approaches unity, the effectiveness typically increases, indicating more efficient heat exchange, while a lower ratio results in reduced effectiveness due to limited heat capacity in one fluid stream.

Mathematical Models for Heat Exchanger Effectiveness

Heat exchanger effectiveness is mathematically modeled using the effectiveness-NTU (Number of Transfer Units) method, where effectiveness (e) depends on the capacity rate ratio (Cr) and NTU values. The capacity rate ratio, defined as the ratio of the minimum to maximum fluid heat capacity rates (C_min/C_max), critically influences the maximum achievable effectiveness, with e increasing as Cr approaches zero. These models accurately predict performance across different heat exchanger types, enabling precise thermal design and optimization based on specific heat capacity flow rates and temperature differentials.

Influence of Capacity Rate Ratio on Heat Transfer Performance

The effectiveness of a heat exchanger is strongly influenced by the capacity rate ratio, defined as the ratio of the minimum to maximum heat capacity rates of the fluids involved. A higher capacity rate ratio tends to decrease heat exchanger effectiveness because the temperature difference driving heat transfer diminishes, limiting thermal energy exchange. Optimizing the capacity rate ratio is critical for maximizing heat transfer performance and achieving efficient thermal management in heat exchanger design.

Typical Effectiveness Curves for Different Exchanger Types

Typical effectiveness curves for different heat exchanger types illustrate the relationship between heat exchanger effectiveness (e) and capacity rate ratio (Cr). Shell-and-tube exchangers generally exhibit moderate effectiveness increasing with Cr, while plate heat exchangers achieve higher effectiveness values at comparable Cr due to enhanced surface area and turbulence. Cross-flow exchangers display lower maximum effectiveness, governed by flow arrangement and heat capacity disparities, crucial for optimizing thermal performance in industrial applications.

Real-World Examples: Effectiveness vs Capacity Rate Ratio

Heat exchanger effectiveness is influenced significantly by the capacity rate ratio, which is the ratio of the minimum to maximum heat capacity rates of the fluids involved. For instance, in shell-and-tube heat exchangers used in chemical plants, a capacity rate ratio close to unity often results in high effectiveness, meaning greater thermal energy transfer efficiency. Real-world data from HVAC systems shows that as the capacity rate ratio decreases, effectiveness drops due to less optimal heat recovery, underscoring the importance of matching fluid flow rates for improved energy efficiency.

Factors Affecting Heat Exchanger Effectiveness

Heat exchanger effectiveness depends significantly on the Capacity Rate Ratio, defined as the ratio of minimum to maximum heat capacity rates of the fluids involved, influencing the overall heat transfer efficiency. Factors such as fluid flow arrangement (counterflow, parallel flow), heat capacity rates, and temperature differences critically impact effectiveness by determining the potential for heat exchange between hot and cold streams. Material properties, fouling resistance, and operational conditions also alter thermal performance by affecting heat transfer coefficients and flow distribution within the exchanger.

Optimizing Design Using Capacity Rate Ratio

Heat exchanger effectiveness measures the actual heat transfer relative to the maximum possible heat transfer between fluids. The capacity rate ratio, defined as the ratio of the minimum to maximum heat capacity rates of the fluid streams, significantly influences this effectiveness by determining the heat exchanger's thermal efficiency. Optimizing heat exchanger design involves adjusting the capacity rate ratio to balance fluid flow rates and heat transfer surfaces, ultimately maximizing thermal performance and minimizing energy losses.

Practical Considerations for Maximizing Exchanger Effectiveness

Maximizing heat exchanger effectiveness requires careful management of the capacity rate ratio, which directly influences the temperature differential driving heat transfer. Ensuring a balanced capacity rate ratio close to unity allows for optimal heat exchange by minimizing temperature crossovers and enhancing thermal performance. Practical considerations include selecting appropriate flow arrangements, maintaining clean surfaces, and controlling fouling to sustain high effectiveness and system efficiency.

Heat exchanger effectiveness and Capacity Rate Ratio Infographic

libterm.com

libterm.com