Material toughness defines a material's ability to absorb energy and resist fracture under stress, combining strength and ductility properties. High toughness is crucial for applications subjected to impact or sudden loads, ensuring reliability and safety. Explore this article to understand how material toughness influences your engineering projects and material selection.

Table of Comparison

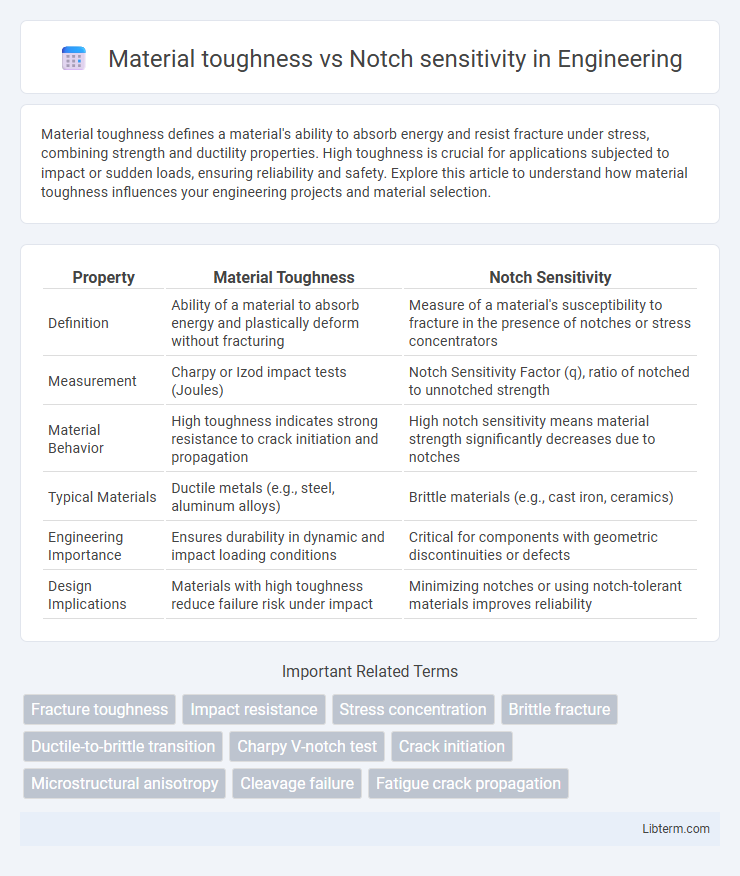

| Property | Material Toughness | Notch Sensitivity |

|---|---|---|

| Definition | Ability of a material to absorb energy and plastically deform without fracturing | Measure of a material's susceptibility to fracture in the presence of notches or stress concentrators |

| Measurement | Charpy or Izod impact tests (Joules) | Notch Sensitivity Factor (q), ratio of notched to unnotched strength |

| Material Behavior | High toughness indicates strong resistance to crack initiation and propagation | High notch sensitivity means material strength significantly decreases due to notches |

| Typical Materials | Ductile metals (e.g., steel, aluminum alloys) | Brittle materials (e.g., cast iron, ceramics) |

| Engineering Importance | Ensures durability in dynamic and impact loading conditions | Critical for components with geometric discontinuities or defects |

| Design Implications | Materials with high toughness reduce failure risk under impact | Minimizing notches or using notch-tolerant materials improves reliability |

Understanding Material Toughness

Material toughness measures a material's ability to absorb energy and plastically deform without fracturing, crucial for resisting impact and sudden loads. Notch sensitivity evaluates how a material's toughness decreases in the presence of stress concentrators like cracks or sharp geometrical changes. Understanding material toughness involves analyzing its stress-strain behavior and fracture mechanics to predict performance under realistic service conditions, especially when notches or defects are present.

What is Notch Sensitivity?

Notch sensitivity measures a material's tendency to experience a significant decrease in toughness when a notch or crack is present. Materials with high notch sensitivity exhibit lower fracture resistance around stress concentrators, leading to easier crack initiation and propagation. Understanding notch sensitivity is crucial in selecting materials for components subject to impact or cyclic loading to prevent sudden failure.

Key Differences Between Toughness and Notch Sensitivity

Material toughness refers to the ability of a material to absorb energy and plastically deform without fracturing, indicating resistance to fracture under impact or sudden loads. Notch sensitivity measures how a material's strength decreases in the presence of a notch or stress concentrator, revealing susceptibility to crack initiation and propagation. The key difference is that toughness represents a bulk property related to energy absorption, while notch sensitivity specifically describes the effect of geometric discontinuities on material performance.

Factors Influencing Material Toughness

Material toughness is significantly influenced by factors such as temperature, strain rate, microstructure, and alloy composition, which determine a material's ability to absorb energy before fracturing. Notch sensitivity is closely related to material toughness, as materials with high toughness tend to exhibit low notch sensitivity due to their ability to distribute stress around flaws or notches. Grain size refinement, the presence of impurities, and heat treatment processes also play critical roles in enhancing toughness and reducing the impact of stress concentrators on material performance.

How Notches Affect Mechanical Properties

Notches significantly reduce material toughness by concentrating stress and promoting crack initiation, leading to premature failure under mechanical loading. The notch sensitivity of a material quantifies how its strength and ductility degrade in the presence of geometric discontinuities, with brittle materials exhibiting higher sensitivity compared to ductile ones. Understanding the interplay between notch geometry and material microstructure is crucial for predicting performance and preventing catastrophic fractures in engineering components.

Testing Methods for Material Toughness

Material toughness is evaluated through impact testing methods such as Charpy and Izod tests, which measure the energy absorbed by a specimen during fracture, reflecting its resistance to crack propagation. Notch sensitivity is assessed by comparing the results of notched and unnotched specimens in these tests, highlighting how stress concentrators influence material performance. Fracture toughness tests, like the ASTM E399 standard, provide quantitative data on crack growth resistance, offering critical insight into notch effects on toughness.

Evaluating Notch Sensitivity in Materials

Evaluating notch sensitivity in materials involves assessing how the presence of notches or geometric discontinuities affect a material's toughness, which reflects its ability to absorb energy before fracturing. Materials with low notch sensitivity demonstrate minimal reduction in toughness despite sharp notches, indicating a high resistance to crack initiation and propagation under stress. Quantitative metrics such as the notch sensitivity factor (q) and fracture toughness (K_IC) are critical for predicting performance in structural applications subjected to impact or cyclic loading.

Materials with High Toughness vs. Notch Sensitivity

Materials with high toughness exhibit superior resistance to crack propagation and impact forces, maintaining structural integrity under stress. Notch sensitivity measures a material's susceptibility to stress concentration around flaws or notches, often higher in brittle materials while toughness reduces this effect. High-toughness materials, such as certain steels and toughened polymers, demonstrate low notch sensitivity, enhancing durability and performance in critical engineering applications.

Engineering Applications: Toughness and Notch Sensitivity

Material toughness represents a material's ability to absorb energy and plastically deform before fracturing, which is critical in engineering applications to prevent catastrophic failure under sudden loads. Notch sensitivity quantifies the reduction in a material's toughness due to the presence of stress concentrators like notches or cracks, influencing component design to avoid premature failure. Engineering designs prioritize materials with high toughness and low notch sensitivity to enhance durability and safety in structural components subjected to impact or cyclic loading.

Strategies to Improve Toughness and Reduce Notch Sensitivity

Enhancing material toughness while reducing notch sensitivity involves optimizing microstructure through techniques such as grain refinement, alloying with elements like nickel or chromium, and heat treatment processes like quenching and tempering. Implementing surface treatments including shot peening or laser shock peening can induce compressive residual stresses, mitigating crack initiation at stress concentrators. Advanced composite design and stress-relief mechanisms also play critical roles in improving fracture resistance and minimizing the detrimental effects of notches in structural applications.

Material toughness Infographic

libterm.com

libterm.com