Material extrusion is a popular 3D printing technique where thermoplastic material is heated and forced through a nozzle to create precise, layer-by-layer objects. This process offers excellent versatility for prototyping and manufacturing with complex geometries and various materials like PLA, ABS, and TPU. Discover how material extrusion can transform Your production capabilities by exploring the full article.

Table of Comparison

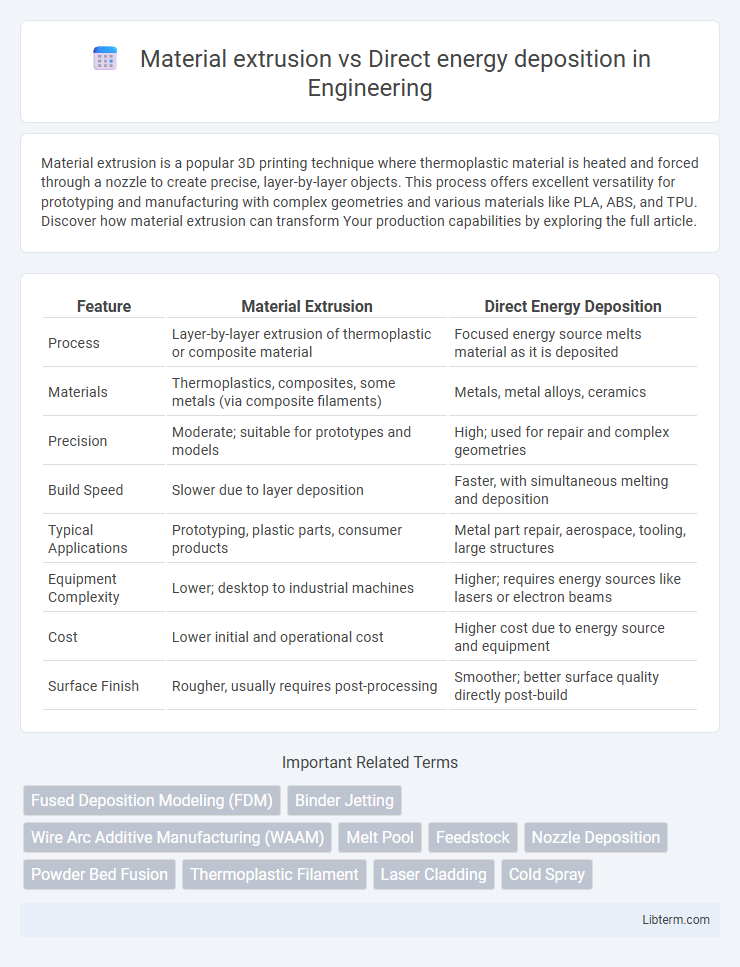

| Feature | Material Extrusion | Direct Energy Deposition |

|---|---|---|

| Process | Layer-by-layer extrusion of thermoplastic or composite material | Focused energy source melts material as it is deposited |

| Materials | Thermoplastics, composites, some metals (via composite filaments) | Metals, metal alloys, ceramics |

| Precision | Moderate; suitable for prototypes and models | High; used for repair and complex geometries |

| Build Speed | Slower due to layer deposition | Faster, with simultaneous melting and deposition |

| Typical Applications | Prototyping, plastic parts, consumer products | Metal part repair, aerospace, tooling, large structures |

| Equipment Complexity | Lower; desktop to industrial machines | Higher; requires energy sources like lasers or electron beams |

| Cost | Lower initial and operational cost | Higher cost due to energy source and equipment |

| Surface Finish | Rougher, usually requires post-processing | Smoother; better surface quality directly post-build |

Introduction to Additive Manufacturing Techniques

Material extrusion is an additive manufacturing technique where thermoplastic materials are heated and deposited layer by layer to build parts with high precision and complex geometries. Direct energy deposition employs focused thermal energy, such as a laser or electron beam, to melt and fuse metal powders or wires as they are simultaneously deposited, enabling repair and fabrication of large-scale components. Both methods offer distinct advantages, with material extrusion excelling in polymer prototyping and direct energy deposition catering to metal part manufacturing and repair in aerospace and industrial applications.

Overview of Material Extrusion

Material extrusion is an additive manufacturing process where thermoplastic filaments or pellets are heated and forced through a nozzle to build parts layer by layer. This technique is widely used for prototyping and functional components due to its cost-effectiveness and versatility with materials like ABS, PLA, and TPU. Unlike direct energy deposition, material extrusion relies on melting and depositing material rather than using focused energy sources to fuse metals or powders.

Fundamentals of Direct Energy Deposition

Direct Energy Deposition (DED) is an additive manufacturing process that builds parts by melting metal powders or wire feedstock with a focused energy source, such as a laser or electron beam, directly onto a substrate. This method enables precise control over the heat input and material placement, allowing for complex geometries and the repair of existing components. Unlike material extrusion, which extrudes thermoplastic filaments layer by layer, DED integrates thermal energy and material deposition simultaneously, resulting in higher density and metallurgical bonding for metal parts.

Key Differences Between Material Extrusion and Direct Energy Deposition

Material extrusion involves the layer-by-layer deposition of thermoplastic or composite materials through a heated nozzle, making it ideal for producing detailed, complex geometries with high surface finish quality. Direct energy deposition uses focused energy sources such as lasers or electron beams to melt feedstock material directly onto a substrate, enabling rapid repair, cladding, and additive manufacturing of metal parts with strong metallurgical bonds. Key differences include material compatibility--material extrusion primarily uses polymers, while direct energy deposition works with metals--and process applications, where extrusion favors prototyping and complex shapes, and energy deposition excels in part repair and high-strength metal fabrication.

Material Compatibility and Selection

Material extrusion primarily supports thermoplastics, composites, and some elastomers, offering a broad compatibility with polymers due to its layer-by-layer filament deposition process. Direct energy deposition excels in processing metals and metal alloys such as titanium, stainless steel, and cobalt-chrome, enabling repair and additive manufacturing with high melting point materials. Material selection between these methods depends on required mechanical properties, thermal stability, and application-specific performance criteria.

Process Parameters and Control

Material extrusion involves controlling parameters such as extrusion temperature, layer height, print speed, and nozzle diameter to achieve precise filament deposition and dimensional accuracy. Direct energy deposition relies on laser power, material feed rate, and scan speed to regulate the melt pool dynamics and ensure strong metallurgical bonding. Accurate control of thermal gradients and feedstock delivery is critical in direct energy deposition to prevent defects and maintain geometric fidelity.

Applications Across Industries

Material extrusion excels in producing complex geometries for automotive prototyping, consumer goods, and aerospace component fabrication, offering precision and cost-efficiency in additive manufacturing. Direct energy deposition is ideal for repairing high-value industrial equipment, such as aerospace turbine blades and oil and gas machinery, by enabling on-site metal deposition and component refurbishment. The combination of these technologies enhances manufacturing versatility across sectors like healthcare, defense, and heavy engineering, addressing both new production and maintenance challenges.

Surface Quality and Mechanical Properties

Material extrusion typically produces parts with moderate surface quality and mechanical properties due to layer-by-layer deposition of thermoplastic or composite materials, which can lead to visible layer lines and anisotropy in strength. Direct energy deposition offers superior mechanical properties and enhanced surface finish by simultaneously melting metal powders or wires with a focused energy source, promoting better metallurgical bonding and reduced porosity. The latter process is preferred for high-performance metal components requiring improved structural integrity and finer surface textures.

Advantages and Limitations of Each Method

Material extrusion offers advantages such as cost-effectiveness, ease of use, and compatibility with various thermoplastics, making it ideal for prototyping and small-scale production. Its limitations include lower mechanical strength and limited material options compared to other additive manufacturing methods. Direct energy deposition enables repair and fabrication of complex metal components with high precision and superior mechanical properties, but it requires expensive equipment, is energy-intensive, and demands skilled operators.

Future Trends in Material Extrusion and Direct Energy Deposition

Future trends in material extrusion emphasize improved multi-material capabilities and finer resolution for complex, customized parts, leveraging advanced polymers and composite filaments. Direct energy deposition is evolving with enhanced precision and automation to enable efficient repair and manufacturing of high-value metal components, integrating real-time monitoring and adaptive control systems. Both technologies are moving toward greater sustainability, incorporating recyclable materials and energy-efficient processes to meet industry demands.

Material extrusion Infographic

libterm.com

libterm.com