Brake mean effective pressure (BMEP) is a key performance metric that measures the average pressure applied on the pistons during the power stroke of an engine, reflecting its efficiency and power output. It allows you to compare engines of different sizes by normalizing torque to engine displacement, providing insight into how effectively the engine converts fuel into mechanical work. Explore the detailed explanations and calculations in the full article to understand how BMEP impacts engine performance.

Table of Comparison

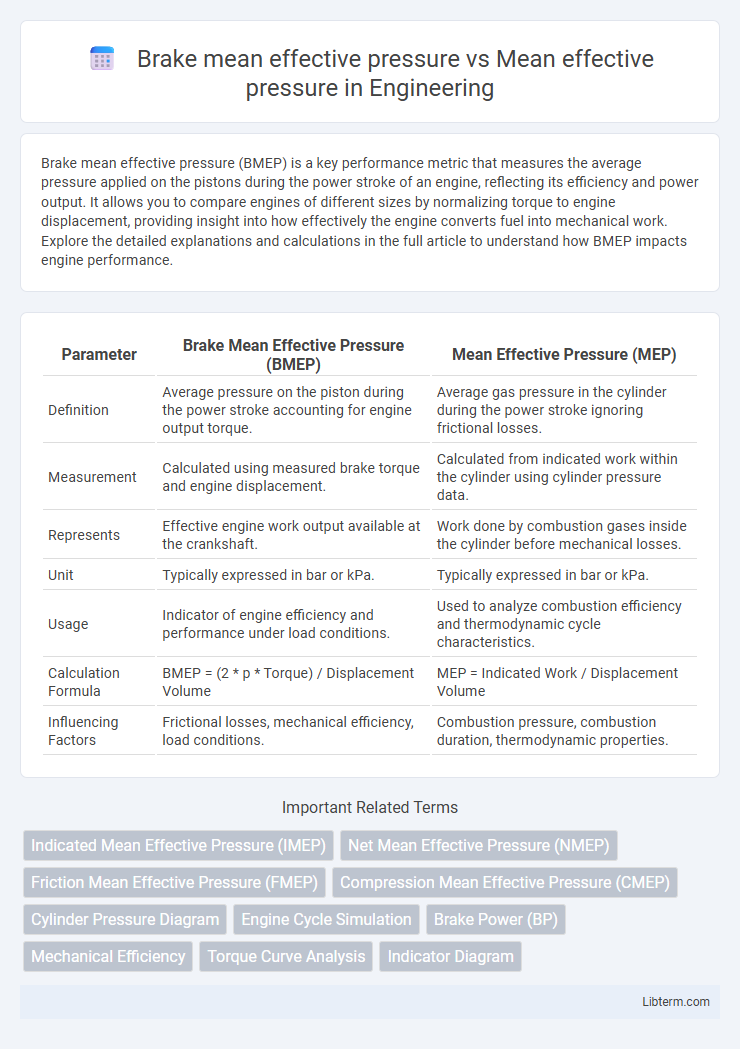

| Parameter | Brake Mean Effective Pressure (BMEP) | Mean Effective Pressure (MEP) |

|---|---|---|

| Definition | Average pressure on the piston during the power stroke accounting for engine output torque. | Average gas pressure in the cylinder during the power stroke ignoring frictional losses. |

| Measurement | Calculated using measured brake torque and engine displacement. | Calculated from indicated work within the cylinder using cylinder pressure data. |

| Represents | Effective engine work output available at the crankshaft. | Work done by combustion gases inside the cylinder before mechanical losses. |

| Unit | Typically expressed in bar or kPa. | Typically expressed in bar or kPa. |

| Usage | Indicator of engine efficiency and performance under load conditions. | Used to analyze combustion efficiency and thermodynamic cycle characteristics. |

| Calculation Formula | BMEP = (2 * p * Torque) / Displacement Volume | MEP = Indicated Work / Displacement Volume |

| Influencing Factors | Frictional losses, mechanical efficiency, load conditions. | Combustion pressure, combustion duration, thermodynamic properties. |

Understanding Brake Mean Effective Pressure (BMEP)

Brake Mean Effective Pressure (BMEP) quantifies the average pressure exerted on the pistons during the power stroke, directly correlating to an engine's torque output at the crankshaft. Unlike Mean Effective Pressure (MEP), which is a theoretical value representing the engine's cylinder pressure without load, BMEP reflects actual engine performance under load by accounting for mechanical losses. Understanding BMEP helps in evaluating engine efficiency, comparing power output across different engines, and optimizing combustion processes for improved fuel economy and reduced emissions.

Overview of Mean Effective Pressure (MEP)

Mean Effective Pressure (MEP) is a critical parameter that represents the average pressure exerted on the piston during the power stroke of an internal combustion engine, serving as a benchmark for engine performance independent of size. Brake Mean Effective Pressure (BMEP) specifically measures the pressure calculated from the brake power output, reflecting the usable engine power after accounting for frictional and mechanical losses. Understanding the distinction between Indicated Mean Effective Pressure (IMEP) and BMEP is essential for evaluating engine efficiency and optimizing design and tuning processes.

Key Differences Between BMEP and MEP

Brake mean effective pressure (BMEP) measures the average pressure exerted on the piston during the power stroke, reflecting the engine's actual output after mechanical losses. Mean effective pressure (MEP) represents the theoretical average pressure in the cylinder, not accounting for friction or other mechanical losses within the engine. The key difference lies in BMEP indicating real useful engine performance, while MEP is primarily a comparative theoretical value for engine design and analysis.

Importance of BMEP in Engine Performance

Brake Mean Effective Pressure (BMEP) quantifies the actual engine output by measuring the effective pressure on the piston during the power stroke after mechanical losses, serving as a direct indicator of engine efficiency and power capability. Mean Effective Pressure (MEP) represents the average pressure in the cylinder throughout the entire cycle without accounting for frictional or mechanical losses, providing a theoretical estimation of engine performance. BMEP is crucial for comparing engine performance across different sizes and configurations, optimizing combustion, fuel efficiency, and overall power output in internal combustion engines.

Calculation Methods for BMEP and MEP

Brake Mean Effective Pressure (BMEP) is calculated by dividing the brake power output of an engine by the product of engine displacement volume and engine speed, reflecting the actual work done on the piston. Mean Effective Pressure (MEP) typically refers to Indicated Mean Effective Pressure (IMEP), which is derived from the indicated power inside the cylinder, obtained by analyzing pressure-volume diagrams from the combustion chamber. BMEP calculation accounts for mechanical losses and friction, making it a more practical measure of engine performance compared to theoretical MEP values.

Factors Affecting Mean Effective Pressure

Brake mean effective pressure (BMEP) is the actual measure of an engine's performance under load, reflecting the net effective pressure exerted on the piston during the power stroke, whereas mean effective pressure (MEP) is a theoretical average pressure representing engine efficiency. Factors affecting mean effective pressure include combustion efficiency, air-fuel mixture quality, intake and exhaust system design, and engine speed. Enhancements in valve timing, fuel injection, and turbocharging significantly increase MEP by optimizing airflow and combustion dynamics.

Applications of BMEP in Engine Diagnostics

Brake Mean Effective Pressure (BMEP) represents the average pressure exerted on the piston during the power stroke, accounting for mechanical losses, and is crucial in evaluating engine performance under real load conditions. Unlike Mean Effective Pressure (MEP), which is a theoretical value based on indicated work, BMEP provides practical insights into engine efficiency by measuring the net output torque relative to displacement volume. In engine diagnostics, BMEP is applied to identify combustion inefficiencies, detect power losses due to friction or valve timing issues, and monitor performance deviations for maintenance and tuning optimization.

Impact of Engine Types on BMEP vs MEP

Brake Mean Effective Pressure (BMEP) represents the actual pressure contributing to useful work output taking into account mechanical losses, while Mean Effective Pressure (MEP) is a theoretical value derived from cylinder pressure without losses. Engine types such as spark-ignition, diesel, and rotary engines exhibit distinct BMEP and MEP profiles due to variations in combustion efficiency, frictional losses, and mechanical design complexities. High-performance diesel engines typically achieve higher BMEP compared to spark-ignition engines, reflecting better thermal efficiency and torque output relative to their theoretical MEP values.

Comparing Indicated Mean Effective Pressure (IMEP) and BMEP

Brake Mean Effective Pressure (BMEP) represents the average pressure exerted on the piston during the power stroke, reflecting the engine's output at the crankshaft, while Indicated Mean Effective Pressure (IMEP) measures the total pressure within the combustion chamber based on cylinder pressure data. The comparison between IMEP and BMEP is essential to evaluate engine mechanical efficiency, where the difference accounts for frictional and mechanical losses within engine components. Higher BMEP values indicate better engine performance and power delivery, whereas the gap between IMEP and BMEP highlights losses due to friction, pumping, and accessory drives.

BMEP vs MEP: Implications for Engine Efficiency

Brake Mean Effective Pressure (BMEP) represents the net pressure acting on the piston during the power stroke after accounting for frictional and mechanical losses, while Mean Effective Pressure (MEP) can be a general term encompassing various forms including Indicated Mean Effective Pressure (IMEP) which reflects the pressure without mechanical losses. Higher BMEP values indicate improved engine efficiency as it directly correlates to the usable work output from the combustion process. Optimizing BMEP relative to MEP reduces mechanical losses and enhances overall fuel efficiency and power output in internal combustion engines.

Brake mean effective pressure Infographic

libterm.com

libterm.com