Vibrations affect everything from machinery performance to human health, making their control and analysis essential in engineering and daily life. Understanding the sources and effects of vibrations can help improve safety, efficiency, and comfort in various environments. Discover how mastering vibration principles can enhance your projects by reading the rest of this article.

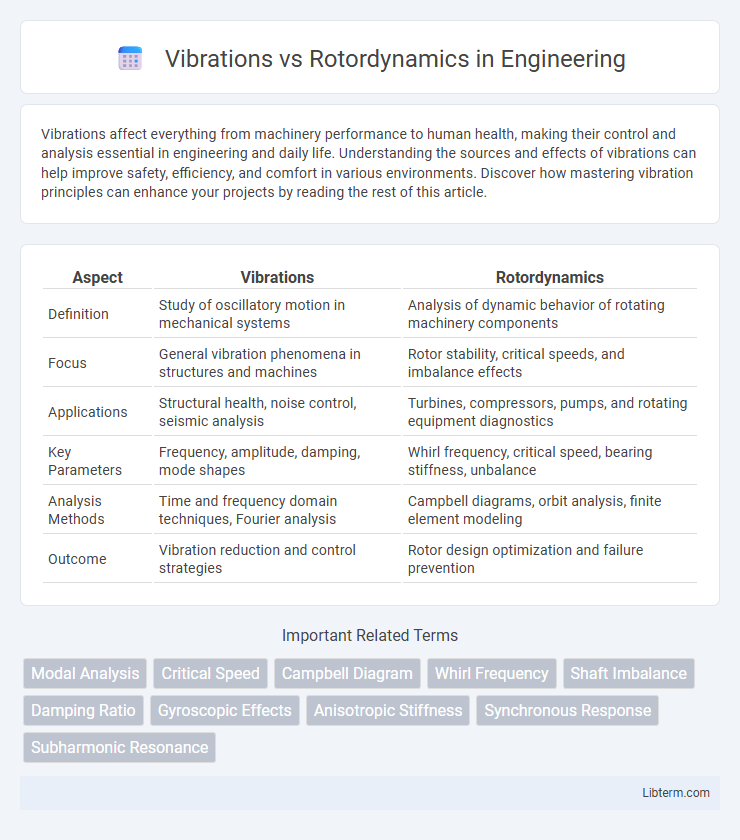

Table of Comparison

| Aspect | Vibrations | Rotordynamics |

|---|---|---|

| Definition | Study of oscillatory motion in mechanical systems | Analysis of dynamic behavior of rotating machinery components |

| Focus | General vibration phenomena in structures and machines | Rotor stability, critical speeds, and imbalance effects |

| Applications | Structural health, noise control, seismic analysis | Turbines, compressors, pumps, and rotating equipment diagnostics |

| Key Parameters | Frequency, amplitude, damping, mode shapes | Whirl frequency, critical speed, bearing stiffness, unbalance |

| Analysis Methods | Time and frequency domain techniques, Fourier analysis | Campbell diagrams, orbit analysis, finite element modeling |

| Outcome | Vibration reduction and control strategies | Rotor design optimization and failure prevention |

Understanding Vibrations in Mechanical Systems

Vibrations in mechanical systems refer to the oscillatory motions caused by dynamic forces acting on components, leading to periodic displacements, velocities, and accelerations. Understanding vibrations involves analyzing natural frequencies, damping ratios, and mode shapes to predict and mitigate resonance, which can cause excessive wear or failure. Rotordynamics specifically studies the behavior of rotating shafts and their interaction with aerodynamic, hydrodynamic, and structural forces, emphasizing critical speed and stability in high-speed rotating machinery.

Introduction to Rotordynamics

Rotordynamics is a specialized branch within mechanical engineering that analyzes the dynamic behavior of rotating machinery components, such as shafts, rotors, and bearings, under operational conditions. It focuses on the study of critical speeds, unbalance response, and stability to prevent excessive vibrations that may lead to mechanical failures. Understanding rotordynamics is crucial for designing reliable rotating equipment in industries like aerospace, power generation, and automotive engineering.

Key Differences: Vibrations vs Rotordynamics

Vibrations refer to the oscillatory motions of mechanical systems around an equilibrium point, encompassing a wide range of frequencies and types, while rotordynamics specifically studies the dynamic behavior of rotating machinery, including shafts, rotors, and bearings, under various operating conditions. Key differences include the scope of analysis--vibrations address general mechanical movements, whereas rotordynamics focuses on phenomena such as whirling, unbalance, and critical speeds unique to rotating systems. Rotordynamics requires specialized models to predict instability and resonance in high-speed rotors, making it crucial for the design and maintenance of turbines, compressors, and engines.

Fundamental Principles of Vibrations

Fundamental principles of vibrations involve the study of oscillatory motions characterized by parameters such as frequency, amplitude, phase, and damping. Vibrations arise from dynamic forces acting on mechanical systems, governed by equations of motion derived from Newtonian mechanics or energy methods. Understanding natural frequencies and mode shapes is critical for diagnosing vibrational behavior, distinguishing them from rotordynamics, which specifically addresses the dynamic behavior of rotating machinery influenced by gyroscopic effects and rotor unbalance.

Core Concepts in Rotordynamics

Rotordynamics focuses on analyzing the dynamic behavior of rotating machinery, emphasizing critical speeds, unbalance, and gyroscopic effects that influence rotor stability and performance. It incorporates modeling of shaft stiffness, damping characteristics, and bearing dynamics to predict vibration amplitudes and potential resonances. Understanding these core concepts allows engineers to design rotors that minimize destructive vibrations, enhance reliability, and prevent catastrophic failures.

Common Causes of Vibrations and Rotor Instabilities

Common causes of vibrations in rotating machinery include unbalance, misalignment, looseness, and structural resonance, which exacerbate stress on components and reduce equipment lifespan. Rotor instabilities arise primarily from fluid-induced forces, bearing failures, and critical speed excursions, leading to self-excited vibrations and potentially catastrophic failures. Understanding the interaction between vibration sources and rotor dynamics is essential for diagnosing and mitigating rotor instabilities in turbines, compressors, and other rotating equipment.

Diagnostic Techniques: Vibrations and Rotordynamics

Vibrations analysis employs techniques such as spectrum analysis, time waveform analysis, and envelope detection to identify imbalance, misalignment, and bearing defects. Rotordynamics diagnostic methods focus on whirl frequency measurements, shaft displacement sensors, and transient response analysis to detect critical speed issues and rotor instabilities. Both disciplines utilize condition monitoring tools like accelerometers and proximity probes to ensure machinery health and prevent catastrophic failures.

Effects of Imbalance and Resonance

Imbalance in rotating machinery generates centrifugal forces that cause excessive vibrations, leading to premature wear and potential structural damage. Resonance occurs when the excitation frequency matches the system's natural frequency, amplifying vibration amplitudes and increasing the risk of catastrophic failure. Effective rotordynamics analysis identifies critical speeds and imbalance effects to ensure vibration mitigation and operational reliability.

Industry Applications: Vibrations vs Rotordynamics

Vibrations analysis and rotordynamics are critical in industries like aerospace, automotive, and power generation for ensuring machinery reliability and safety. Vibrations focus on detecting abnormal oscillations in components, while rotordynamics specifically examines the dynamic behavior of rotating shafts to prevent failures such as unbalance, misalignment, and bearing damage. Effective monitoring and control of both vibrations and rotordynamics improve equipment lifespan, reduce downtime, and optimize performance in industrial applications.

Advances in Vibration and Rotordynamics Analysis

Recent advances in vibration and rotordynamics analysis leverage high-fidelity finite element models and real-time condition monitoring systems to enhance the accuracy of fault diagnosis in rotating machinery. Integration of machine learning algorithms with traditional rotordynamics simulations enables predictive maintenance by identifying early signs of imbalance, misalignment, and bearing defects. These technological improvements significantly reduce downtime and extend the operational life of turbines, compressors, and industrial pumps.

Vibrations Infographic

libterm.com

libterm.com