Pipe vibration occurs due to fluid flow, mechanical forces, or external disturbances, leading to potential damage and noise issues. Proper design and support systems can minimize these vibrations, ensuring operational safety and longevity. Explore this article to learn effective methods for controlling and diagnosing pipe vibration problems.

Table of Comparison

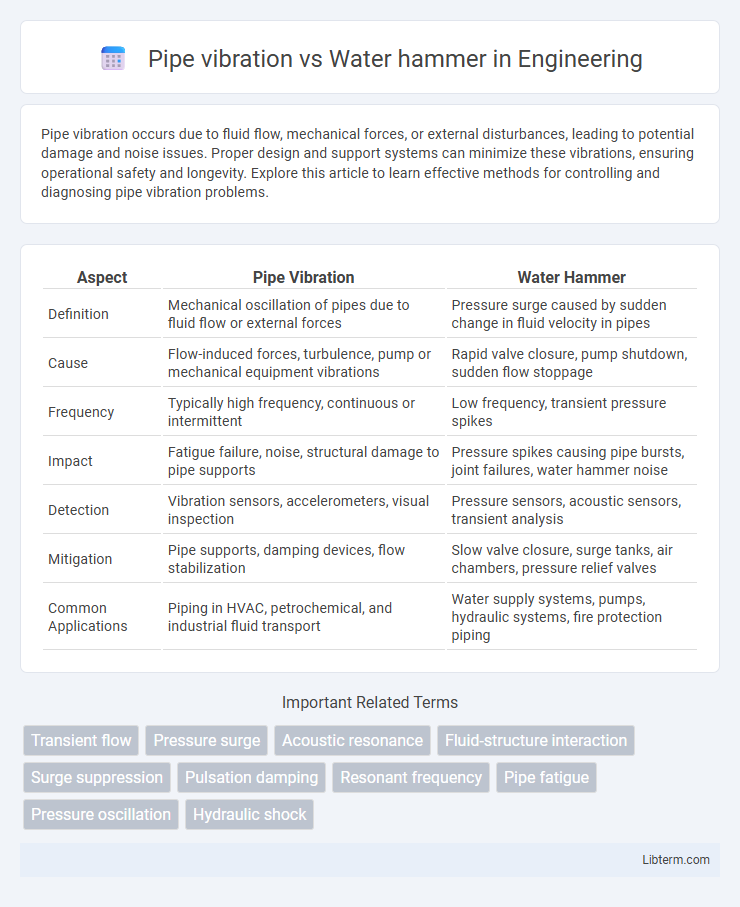

| Aspect | Pipe Vibration | Water Hammer |

|---|---|---|

| Definition | Mechanical oscillation of pipes due to fluid flow or external forces | Pressure surge caused by sudden change in fluid velocity in pipes |

| Cause | Flow-induced forces, turbulence, pump or mechanical equipment vibrations | Rapid valve closure, pump shutdown, sudden flow stoppage |

| Frequency | Typically high frequency, continuous or intermittent | Low frequency, transient pressure spikes |

| Impact | Fatigue failure, noise, structural damage to pipe supports | Pressure spikes causing pipe bursts, joint failures, water hammer noise |

| Detection | Vibration sensors, accelerometers, visual inspection | Pressure sensors, acoustic sensors, transient analysis |

| Mitigation | Pipe supports, damping devices, flow stabilization | Slow valve closure, surge tanks, air chambers, pressure relief valves |

| Common Applications | Piping in HVAC, petrochemical, and industrial fluid transport | Water supply systems, pumps, hydraulic systems, fire protection piping |

Understanding Pipe Vibration: Causes and Effects

Pipe vibration occurs when fluid flow induces oscillations in the piping system, primarily caused by turbulence, vortex shedding, and mechanical equipment such as pumps or compressors. These vibrations can lead to structural fatigue, joint failures, and increased noise levels, impacting the longevity and safety of the piping infrastructure. Understanding the frequency, amplitude, and sources of pipe vibration is essential for designing effective mitigation strategies and preventing costly damage.

What Is Water Hammer? Definition and Mechanism

Water hammer is a pressure surge or wave caused when a fluid in motion is forced to stop or change direction suddenly within a pipe system. This phenomenon occurs due to the rapid closure of valves, pump failures, or quick changes in flow velocity, generating shock waves that travel through the piping. Unlike pipe vibration, which involves mechanical oscillations of the pipe structure, water hammer specifically refers to the transient hydraulic shock impacting the fluid and piping integrity.

Key Differences: Pipe Vibration vs Water Hammer

Pipe vibration involves continuous oscillations caused by mechanical faults, flow turbulence, or resonant frequencies in piping systems, leading to noise and potential structural fatigue. Water hammer is a transient pressure surge caused by sudden valve closure or rapid changes in fluid velocity, resulting in shock waves that can cause pipe rupture or joint failure. The key difference lies in the nature of the forces: pipe vibration is a steady-state oscillation, whereas water hammer is a high-intensity, short-duration pressure spike.

Common Sources of Pipe Vibration in Plumbing Systems

Common sources of pipe vibration in plumbing systems include loose pipe supports, turbulent flow caused by abrupt changes in pipe diameter or direction, and mechanical equipment such as pumps and valves operating at high speeds. These vibrations differ from water hammer, which is a pressure surge resulting from sudden valve closure or rapid flow changes, but both phenomena can cause damage if not properly managed. Proper installation, secure mounting, and use of vibration dampeners help mitigate pipe vibrations and maintain system integrity.

Main Triggers for Water Hammer Events

Water hammer events are primarily triggered by sudden changes in fluid velocity, such as rapid valve closures or pump startups and shutdowns, causing pressure surges that can damage pipe systems. In contrast, pipe vibration typically results from flow turbulence, mechanical resonance, or equipment imbalances rather than abrupt flow changes. Understanding the distinct triggers for water hammer enables engineers to design effective mitigation measures like surge tanks or air chambers to protect piping infrastructure.

Identifying Symptoms: Pipe Vibration vs Water Hammer

Pipe vibration typically manifests as continuous or intermittent shaking and rattling along the pipeline, often accompanied by a humming or rattling noise caused by mechanical resonance or fluid turbulence. Water hammer is characterized by sudden, sharp banging noises and pressure surges resulting from rapid valve closures or abrupt changes in water flow, leading to intense shock waves within the pipe. Identifying symptoms involves distinguishing the persistent oscillations and noise of pipe vibration from the abrupt, high-pressure pulses and knocking sounds indicative of water hammer events.

Potential Damages Caused by Each Phenomenon

Pipe vibration can cause structural fatigue, leading to pipe wall thinning, joint loosening, and failure of supports or hangers due to continuous oscillations. Water hammer generates sudden pressure surges that can result in pipe rupture, flange separation, valve damage, and severe stress on pumping equipment. Both phenomena pose significant risks to pipeline integrity, with vibration causing progressive damage and water hammer causing immediate, catastrophic failures.

Diagnostic Techniques for Pipe Vibration and Water Hammer

Diagnostic techniques for pipe vibration include accelerometer measurements, laser vibrometry, and frequency spectrum analysis to identify excitation sources and resonance frequencies. Water hammer diagnosis relies on pressure transducers and high-speed data acquisition systems to capture transient pressure spikes and waveform patterns within pipelines. Combining computational fluid dynamics (CFD) simulations with real-time monitoring enhances accuracy in detecting and differentiating between pipe vibration and water hammer phenomena.

Prevention and Mitigation Strategies

Pipe vibration and water hammer both pose risks to piping systems, but their prevention methods differ. To prevent pipe vibration, secure support brackets and flexible connectors can reduce oscillations caused by fluid flow or mechanical equipment. Water hammer mitigation requires installing air chambers, surge tanks, or pressure relief valves to absorb sudden pressure changes and protect pipe integrity.

Choosing the Right Solution: Addressing Pipe Vibration and Water Hammer

Evaluating pipe vibration and water hammer requires identifying root causes such as fluid velocity, pressure surges, and mechanical resonance to select appropriate mitigation strategies. Implementing solutions like vibration dampeners, pressure relief valves, or air chambers effectively reduces structural stress and noise. Tailoring interventions based on precise system diagnostics ensures optimized performance and longevity of piping infrastructure.

Pipe vibration Infographic

libterm.com

libterm.com