Yield strength measures the stress at which a material begins to deform plastically, indicating the limit before permanent deformation occurs. It is crucial in engineering and design to ensure structural components can withstand applied forces without failure. Explore the full article to understand how yield strength impacts material selection and performance in various applications.

Table of Comparison

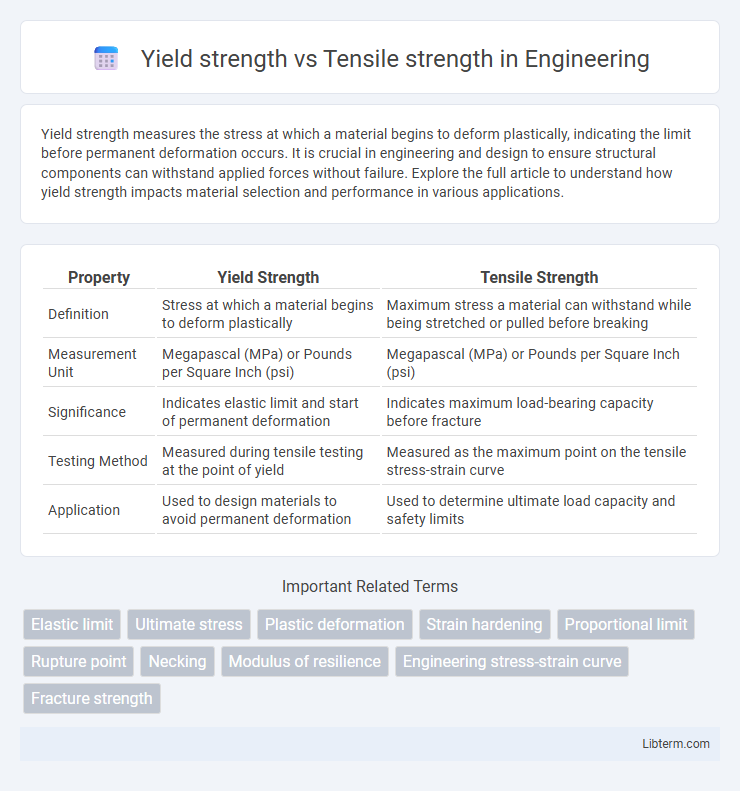

| Property | Yield Strength | Tensile Strength |

|---|---|---|

| Definition | Stress at which a material begins to deform plastically | Maximum stress a material can withstand while being stretched or pulled before breaking |

| Measurement Unit | Megapascal (MPa) or Pounds per Square Inch (psi) | Megapascal (MPa) or Pounds per Square Inch (psi) |

| Significance | Indicates elastic limit and start of permanent deformation | Indicates maximum load-bearing capacity before fracture |

| Testing Method | Measured during tensile testing at the point of yield | Measured as the maximum point on the tensile stress-strain curve |

| Application | Used to design materials to avoid permanent deformation | Used to determine ultimate load capacity and safety limits |

Introduction to Yield Strength and Tensile Strength

Yield strength represents the stress level at which a material begins to deform plastically, marking the transition from elastic to permanent deformation. Tensile strength, also known as ultimate tensile strength (UTS), is the maximum stress a material can withstand while being stretched or pulled before breaking. Understanding these two mechanical properties is critical for material selection in engineering applications to ensure structural integrity and performance.

Defining Yield Strength

Yield strength defines the maximum stress a material can withstand without permanent deformation, marking the transition from elastic to plastic behavior. Tensile strength, by contrast, measures the maximum stress a material can endure before breaking. Understanding yield strength is crucial for engineering applications where structural integrity under load is essential.

Defining Tensile Strength

Tensile strength refers to the maximum stress a material can withstand while being stretched or pulled before breaking. It is a critical mechanical property measured during a tensile test and indicates the material's overall resistance to failure under tension. Yield strength, by contrast, marks the stress level at which permanent deformation begins, distinguishing elastic behavior from plastic deformation.

Key Differences Between Yield Strength and Tensile Strength

Yield strength represents the maximum stress a material can withstand without permanent deformation, while tensile strength is the highest stress a material can endure before fracturing. Yield strength is crucial for determining the elastic limit and ensures structural integrity under load, whereas tensile strength indicates the ultimate load the material can bear before failure. The key difference lies in yield strength marking the onset of plastic deformation and tensile strength identifying the maximum stress before rupture.

Importance of Yield Strength in Material Selection

Yield strength is a critical parameter in material selection as it defines the maximum stress a material can withstand without permanent deformation, ensuring structural integrity under operational loads. Compared to tensile strength, which represents the maximum stress before failure, yield strength provides a more practical limit for design safety and serviceability. Engineers prioritize yield strength to prevent plastic deformation, maintain dimensional stability, and extend the lifespan of components under cyclic or static loads.

Significance of Tensile Strength in Engineering Applications

Tensile strength represents the maximum stress a material can withstand while being stretched or pulled before breaking, crucial for ensuring structural integrity in engineering applications. It determines a material's ability to resist failure under tension, making it vital for designing components subjected to dynamic or extreme loads. Unlike yield strength, tensile strength defines the ultimate performance limit, guiding safety factors and material selection in critical engineering projects.

Factors Influencing Yield and Tensile Strength

Yield strength and tensile strength are influenced by factors such as alloy composition, heat treatment, and grain size; increasing alloying elements like carbon typically enhances both strengths by impeding dislocation movement. Heat treatments like quenching and tempering refine microstructure and improve strength properties, while finer grain size increases yield strength through the Hall-Petch relationship by blocking dislocation motion. Impurities, strain rate, and temperature also critically affect these strengths, with higher temperatures generally reducing both yield and tensile strength due to increased atomic vibrations.

Methods for Measuring Yield and Tensile Strength

Yield strength is typically measured using a tensile test where the stress at which a material begins to deform plastically is identified by the 0.2% offset method, which involves drawing a parallel line to the elastic portion of the stress-strain curve. Tensile strength is determined by the maximum stress recorded on the stress-strain curve during the same tensile test, representing the highest load a material can withstand before necking and failure. Both measurements use universal testing machines equipped with extensometers or strain gauges to precisely capture stress and strain data throughout the deformation process.

Real-World Examples: Yield vs. Tensile Strength

Yield strength represents the stress at which a material begins to deform plastically, while tensile strength indicates the maximum stress a material can withstand before failure. For example, in automotive steel, the yield strength determines how much load the frame can handle before permanent deformation, whereas tensile strength defines the limit before breaking during a crash. Aerospace alloys showcase high tensile strength for withstanding extreme forces but require a precise yield strength to avoid structural failure under repeated stress cycles.

Conclusion: Choosing the Right Strength Parameter

Yield strength is crucial for applications requiring material deformation limits without permanent damage, whereas tensile strength indicates the maximum stress a material can endure before breaking, guiding design safety margins. Selecting the appropriate strength parameter depends on the specific engineering requirements, such as structural integrity under elastic deformation or ultimate failure prevention. Designers prioritize yield strength for elastic performance and tensile strength for maximum load-bearing capacity to ensure optimal material utilization and safety.

Yield strength Infographic

libterm.com

libterm.com