Chip formation is a critical process in machining where material is removed from a workpiece in the form of small fragments called chips. Understanding the mechanisms of chip formation helps improve cutting efficiency, tool life, and surface finish. Explore the rest of this article to discover how mastering chip formation can enhance your manufacturing results.

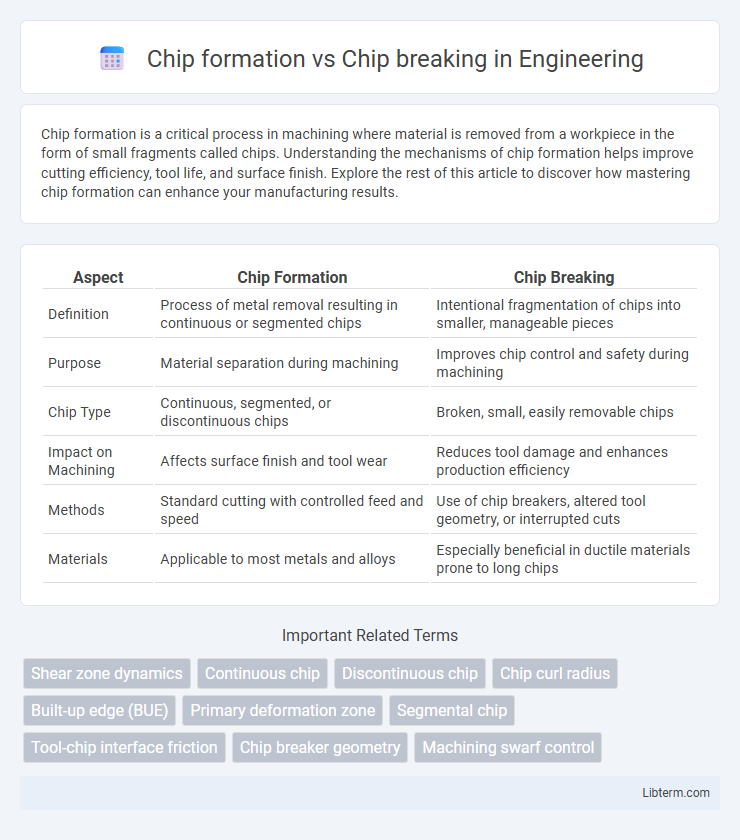

Table of Comparison

| Aspect | Chip Formation | Chip Breaking |

|---|---|---|

| Definition | Process of metal removal resulting in continuous or segmented chips | Intentional fragmentation of chips into smaller, manageable pieces |

| Purpose | Material separation during machining | Improves chip control and safety during machining |

| Chip Type | Continuous, segmented, or discontinuous chips | Broken, small, easily removable chips |

| Impact on Machining | Affects surface finish and tool wear | Reduces tool damage and enhances production efficiency |

| Methods | Standard cutting with controlled feed and speed | Use of chip breakers, altered tool geometry, or interrupted cuts |

| Materials | Applicable to most metals and alloys | Especially beneficial in ductile materials prone to long chips |

Introduction to Chip Formation and Chip Breaking

Chip formation refers to the process where material is removed from a workpiece during machining, creating continuous or segmented chips depending on factors like tool geometry and cutting conditions. Chip breaking involves intentionally controlling chip shape and size to produce smaller, manageable chips that reduce machining hazards and improve surface quality. Effective chip breaking enhances machining efficiency by preventing long, entangling chips and ensuring smoother material removal.

Fundamentals of Chip Formation in Machining

Chip formation in machining is a fundamental process where the cutting tool shears material from the workpiece, generating continuous or segmented chips based on the material properties and cutting conditions. Chip breaking refers to the intentional disruption of these chips into smaller, manageable pieces to prevent entanglement and improve surface finish and tool life. Understanding the mechanics of chip formation, including shear strain, strain rate, and temperature effects, is crucial for optimizing cutting parameters and tool geometry in various machining operations.

Mechanisms Behind Chip Formation

Chip formation in machining involves the plastic deformation of the workpiece material ahead of the cutting tool, where shear forces cause the material to separate and form a continuous chip characterized by distinct shear zones. Chip breaking occurs when the continuous chip is fractured into smaller segments due to the application of stresses exceeding the material's fracture strength, which enhances chip control and reduces machining issues. Understanding the mechanisms behind chip formation, such as shear localization, strain hardening, and thermal softening, is crucial for optimizing cutting parameters and tool geometry to achieve efficient material removal and improved surface finish.

Importance of Chip Breaking in Metal Cutting

Effective chip breaking in metal cutting is crucial to prevent the formation of long, continuous chips that can damage the workpiece and cutting tool. Proper chip formation and controlled chip breaking enhance machining efficiency by reducing heat generation, minimizing tool wear, and improving surface finish quality. Industrial applications prioritize chip breaking to ensure safer operation, maintain dimensional accuracy, and facilitate automated chip removal systems.

Factors Influencing Chip Formation

Chip formation during machining is primarily influenced by material properties, cutting speed, feed rate, and tool geometry, which determine the type and morphology of the chip produced. Harder materials and higher cutting speeds generally promote continuous chip formation, while brittle materials and increased feed rates tend to favor discontinuous or segmented chips. Tool rake angle and depth of cut also play critical roles in chip thickness and chip breaking, directly affecting machining efficiency and surface finish quality.

Techniques and Tools for Effective Chip Breaking

Effective chip breaking techniques involve using specialized cutting tools with chip breakers designed to create smaller, more manageable chips during machining. Tools such as inserts with segmented or grooved geometries optimize chip formation by controlling chip size and shape, reducing tool wear and improving surface finish. Advanced methods include adjusting cutting parameters like feed rate and depth of cut, along with employing coolant systems to enhance chip evacuation and prevent chip entanglement.

Differences Between Continuous and Discontinuous Chips

Continuous chips form during machining processes with ductile materials, resulting in long, continuous strands that provide a smooth cutting action and better surface finish. Discontinuous chips, typical with brittle materials, break into small segments due to cracks formed ahead of the cutting edge, reducing heat generation but potentially causing vibrations. The main differences lie in chip morphology and material behavior: continuous chips exhibit uniform thickness while discontinuous chips show segmented fractures that influence machining stability and efficiency.

Impact of Cutting Parameters on Chip Control

Cutting parameters such as feed rate, cutting speed, and depth of cut significantly impact chip formation and chip breaking, directly influencing machining efficiency and surface quality. Higher cutting speeds and optimal feed rates promote continuous chip formation, while specific parameter adjustments induce chip fragmentation, enhancing chip control and reducing tool wear. Precise control of cutting parameters ensures effective chip breaking, minimizing heat generation and improving chip evacuation during metal cutting processes.

Advantages of Optimized Chip Formation and Breaking

Optimized chip formation and breaking enhance machining efficiency by reducing tool wear and minimizing heat generation, leading to prolonged tool life and improved surface finish. Efficient chip control prevents machine damage and ensures safer operation by avoiding chip entanglement or disposal issues. This optimization also contributes to better material removal rates and energy savings, boosting overall productivity in manufacturing processes.

Innovations and Future Trends in Chip Management

Innovations in chip formation focus on enhancing tool geometry and material properties to optimize continuous chip flow, reducing heat and tool wear for precision machining. Future trends in chip breaking emphasize smart sensing technology and adaptive control systems to dynamically adjust cutting parameters, enabling efficient management of chip size and disposal. Integration of AI-driven analytics and real-time monitoring will revolutionize chip management by minimizing downtime and improving overall manufacturing sustainability.

Chip formation Infographic

libterm.com

libterm.com