A pull rod is a critical component in automotive suspension systems, transferring forces from the wheel assembly to the chassis to improve handling and stability. Commonly found in high-performance racing vehicles, the pull rod allows for lower center of gravity and enhanced aerodynamic efficiency by enabling compact suspension layouts. Explore the rest of this article to understand how a pull rod can enhance your vehicle's performance and design.

Table of Comparison

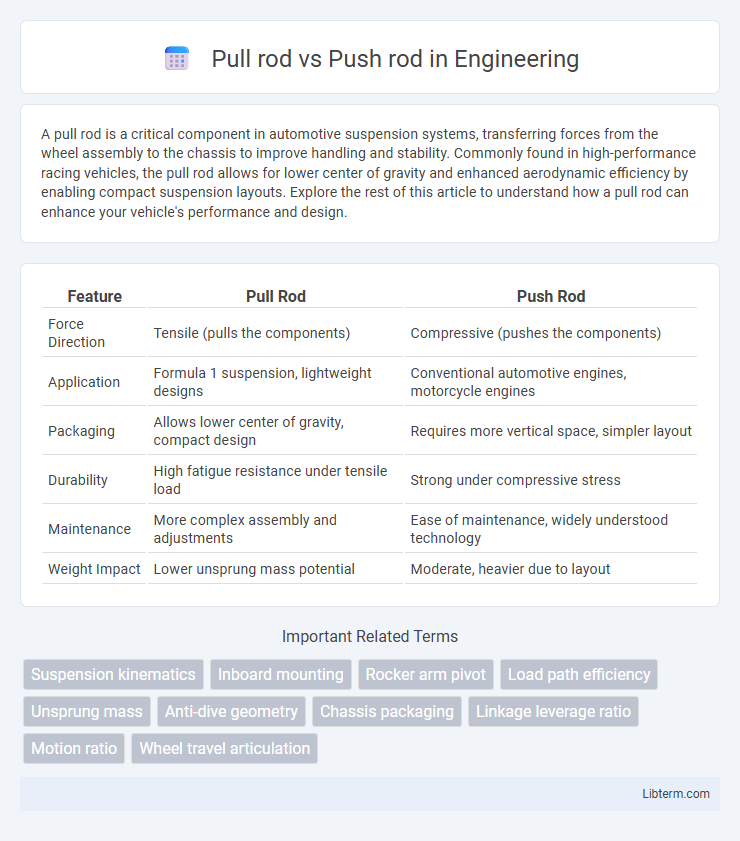

| Feature | Pull Rod | Push Rod |

|---|---|---|

| Force Direction | Tensile (pulls the components) | Compressive (pushes the components) |

| Application | Formula 1 suspension, lightweight designs | Conventional automotive engines, motorcycle engines |

| Packaging | Allows lower center of gravity, compact design | Requires more vertical space, simpler layout |

| Durability | High fatigue resistance under tensile load | Strong under compressive stress |

| Maintenance | More complex assembly and adjustments | Ease of maintenance, widely understood technology |

| Weight Impact | Lower unsprung mass potential | Moderate, heavier due to layout |

Introduction to Pull Rod and Push Rod Systems

Pull rod and push rod systems are essential components in automotive suspension design, controlling the movement and stability of the vehicle's wheels. Pull rod systems transfer forces through tension, where the rod is pulled under load, resulting in a lower center of gravity and improved aerodynamics in high-performance vehicles. Push rod systems operate by transferring forces through compression, pushing the rod under load, which allows for easier packaging and maintenance in race cars and road vehicles.

Key Differences Between Pull Rod and Push Rod Mechanisms

Pull rod and push rod mechanisms differ primarily in their force transmission direction and placement within suspension systems. Pull rods transmit force by tension, pulling the suspension components upward, resulting in a lower center of gravity and better airflow in race car designs, while push rods operate under compression, pushing components downward and typically allowing easier access for maintenance. The choice between these systems impacts vehicle handling characteristics, weight distribution, and mechanical complexity.

Historical Evolution of Suspension Designs

Early automotive suspension designs predominantly utilized push rod systems due to their straightforward mechanical layout and easier integration with solid axles. The evolution toward pull rod suspension emerged in high-performance and racing vehicles, offering improved aerodynamics and lower center of gravity by allowing components to be mounted lower in the chassis. Advances in materials and engineering precision facilitated this transition, enabling more sophisticated load distribution and enhanced handling characteristics in modern suspension architectures.

Mechanical Principles Behind Each System

Pull rod and push rod systems differ primarily in their mechanical operation of transferring forces in suspension setups. Pull rods operate under tension, pulling components together when the suspension compresses, which enhances chassis stiffness and lowers the center of gravity by allowing lower placement of suspension elements. Push rods work under compression, pushing components upward to transfer loads, offering simpler geometry and easier maintenance but potentially raising the center of gravity due to higher placement of components.

Performance Implications in Motorsports

Pull rod suspension systems provide improved aerodynamic efficiency by lowering the car's center of gravity and reducing the frontal area, essential in Formula 1 and high-performance motorsports. Push rod setups offer easier accessibility for setup adjustments and increased suspension stiffness, benefiting rapid response on track conditions. The choice between pull rod and push rod impacts handling precision, vehicle balance, and overall lap times, with teams selecting based on circuit characteristics and aerodynamic priorities.

Weight Distribution and Center of Gravity Effects

Pull rod suspension systems lower the center of gravity by positioning suspension components lower in the chassis, enhancing weight distribution and improving vehicle stability. In contrast, push rod setups place key elements higher, potentially raising the center of gravity and affecting balance negatively during high-speed maneuvers. Optimizing weight distribution with pull rods benefits overall handling by reducing body roll and increasing tire contact patch consistency.

Maintenance and Durability Considerations

Pull rod suspension systems require less frequent maintenance due to their simpler design and reduced number of moving components, which enhances overall durability. Push rod setups often experience higher wear on joints and rods, necessitating more regular inspections and component replacements to maintain optimal performance. Material quality and environmental factors significantly influence the longevity of both systems, with corrosion-resistant alloys improving maintenance intervals and durability.

Real-world Applications: Road vs. Race Cars

Pull rod suspension systems offer lower center of gravity and improved aerodynamics, making them ideal for high-performance race cars seeking maximum handling precision. Push rod setups provide greater durability and easier maintenance, commonly preferred in road cars where comfort and reliability outweigh extreme performance. The selection between pull rod and push rod depends on balancing stiffness, packaging constraints, and vehicle application requirements.

Cost Analysis and Engineering Complexity

Pull rod suspension systems generally incur higher manufacturing costs due to the need for precise engineering and specialized materials to maintain rigidity and reduce weight. Push rod setups tend to be less complex mechanically, translating to lower production expenses and easier maintenance. Engineering complexity in pull rod designs often results in increased design iteration time and tooling costs, impacting overall project budgets.

Future Trends in Suspension Technology

Push rod and pull rod suspension systems are evolving with advancements in lightweight materials and active suspension technologies, enhancing vehicle handling and efficiency. Future trends emphasize integrating electronic controls and adaptive dampers to improve real-time responsiveness and energy recovery capabilities. Innovations in sensor integration and AI-driven adjustments aim to optimize suspension behavior for varying driving conditions and autonomous vehicle requirements.

Pull rod Infographic

libterm.com

libterm.com