Mean Time to Repair (MTTR) measures the average time required to diagnose and fix a system failure, highlighting maintenance efficiency and operational reliability. Reducing MTTR can significantly minimize downtime, improve productivity, and enhance overall equipment effectiveness in your organization. Discover practical strategies and tools to optimize MTTR by reading the rest of the article.

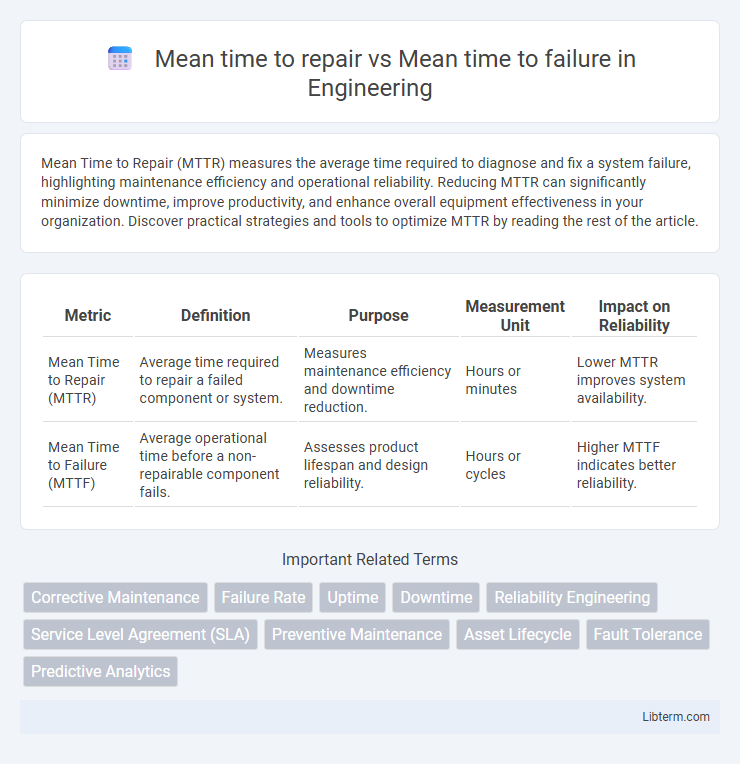

Table of Comparison

| Metric | Definition | Purpose | Measurement Unit | Impact on Reliability |

|---|---|---|---|---|

| Mean Time to Repair (MTTR) | Average time required to repair a failed component or system. | Measures maintenance efficiency and downtime reduction. | Hours or minutes | Lower MTTR improves system availability. |

| Mean Time to Failure (MTTF) | Average operational time before a non-repairable component fails. | Assesses product lifespan and design reliability. | Hours or cycles | Higher MTTF indicates better reliability. |

Understanding Mean Time to Repair (MTTR)

Mean Time to Repair (MTTR) measures the average time required to diagnose, repair, and restore a system or component to full functionality after a failure, reflecting maintenance efficiency. It is crucial for assessing response effectiveness and minimizing downtime in operational environments. MTTR differs from Mean Time to Failure (MTTF), which indicates the expected operational lifespan before a failure occurs, focusing on reliability rather than repair speed.

What is Mean Time to Failure (MTTF)?

Mean Time to Failure (MTTF) is a key reliability metric that measures the average operational time before a non-repairable system or component fails. It provides critical data for predicting product lifespan and maintenance scheduling, especially in systems where failure leads to complete replacement. MTTF differs from Mean Time to Repair (MTTR), which tracks the average time required to fix a repairable device after failure occurs.

Key Differences Between MTTR and MTTF

Mean Time to Repair (MTTR) measures the average time required to fix a system or component after a failure, emphasizing repair efficiency and downtime reduction. Mean Time to Failure (MTTF) represents the expected operational lifespan of a non-repairable item before it fails, highlighting reliability and durability. Key differences include MTTR focusing on maintenance and recovery speed, while MTTF emphasizes the duration of continuous, failure-free performance.

Importance of MTTR and MTTF in Reliability Engineering

Mean Time to Repair (MTTR) and Mean Time to Failure (MTTF) are critical metrics in reliability engineering that quantify system maintenance and operational lifespan, respectively. MTTR measures the average time required to restore a system after a failure, directly impacting downtime and maintenance efficiency. MTTF estimates the expected operational duration before a failure occurs, guiding design improvements and reliability predictions for enhancing overall system performance.

Calculating MTTR: Methods and Best Practices

Calculating Mean Time to Repair (MTTR) involves summing the total downtime for repairs divided by the number of repair incidents, providing a key metric for maintenance efficiency. Best practices include accurately logging start and end times of each repair, standardizing repair procedures to reduce variability, and using statistical tools like moving averages to analyze trends. Comparing MTTR with Mean Time to Failure (MTTF) helps identify equipment reliability and optimize maintenance schedules to minimize overall system downtime.

Calculating MTTF: Methods and Best Practices

Calculating Mean Time to Failure (MTTF) involves analyzing historical failure data to determine the average operational time before a component or system fails. Common methods include statistical analysis using exponential or Weibull distributions, reliability block diagrams, and life testing under controlled conditions to model failure rates accurately. Best practices emphasize consistent data collection, removing outliers, and regularly updating calculations to reflect changes in operational environments or maintenance strategies for precise reliability predictions.

Impact of MTTR and MTTF on System Downtime

Mean Time to Repair (MTTR) directly affects system downtime by defining the average duration required to restore a system after a failure, with shorter MTTR leading to quicker recovery and reduced operational interruptions. Mean Time to Failure (MTTF) measures the average operational lifespan before a system or component fails, influencing the frequency of downtime events. Optimizing MTTR minimizes repair time, while extending MTTF reduces failure incidents, both critical for enhancing overall system availability and reliability.

Practical Applications of MTTR and MTTF

Mean Time to Repair (MTTR) measures the average time required to fix a failed component, optimizing maintenance workflows and reducing downtime in manufacturing and IT infrastructure. Mean Time to Failure (MTTF) estimates the expected operational lifespan of non-repairable systems, guiding reliability engineering and product lifecycle management. Combining MTTR and MTTF enhances asset management strategies, improving system availability and maintenance cost forecasting across industries.

MTTR vs MTTF in Predictive Maintenance

Mean Time to Repair (MTTR) measures the average duration required to fix a failed component and restore it to operational condition, serving as a critical metric in predictive maintenance for minimizing downtime. Mean Time to Failure (MTTF) indicates the expected operational lifespan of a non-repairable asset before failure, helping maintenance teams predict when replacements or interventions are necessary. Analyzing both MTTR and MTTF enables optimized maintenance scheduling by balancing repair efficiency with failure prediction, reducing unplanned outages and enhancing asset reliability.

Improving Performance: Strategies to Optimize MTTR and MTTF

Improving performance by optimizing Mean Time to Repair (MTTR) and Mean Time to Failure (MTTF) involves implementing predictive maintenance technologies and leveraging real-time monitoring systems to reduce downtime and extend equipment lifespan. Utilizing data analytics and machine learning models helps identify failure patterns and optimize repair processes, decreasing MTTR while increasing MTTF. Enhancing training programs for maintenance personnel and standardizing repair protocols also contribute to faster recovery times and improved asset reliability.

Mean time to repair Infographic

libterm.com

libterm.com