Gas tungsten arc welding (GTAW), also known as TIG welding, delivers precise, high-quality welds by using a non-consumable tungsten electrode and an inert gas shield to protect the weld pool. This technique excels in welding thin materials and critical joints where strength and appearance are paramount. Discover how mastering GTAW can enhance Your welding projects by exploring the detailed insights ahead.

Table of Comparison

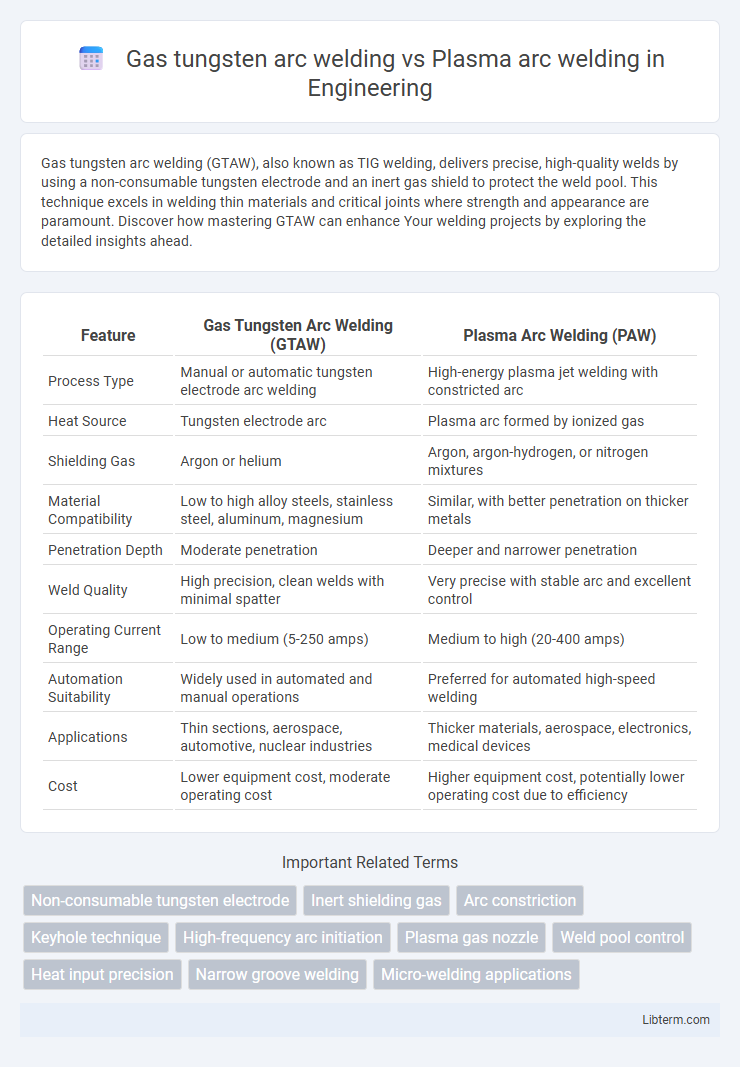

| Feature | Gas Tungsten Arc Welding (GTAW) | Plasma Arc Welding (PAW) |

|---|---|---|

| Process Type | Manual or automatic tungsten electrode arc welding | High-energy plasma jet welding with constricted arc |

| Heat Source | Tungsten electrode arc | Plasma arc formed by ionized gas |

| Shielding Gas | Argon or helium | Argon, argon-hydrogen, or nitrogen mixtures |

| Material Compatibility | Low to high alloy steels, stainless steel, aluminum, magnesium | Similar, with better penetration on thicker metals |

| Penetration Depth | Moderate penetration | Deeper and narrower penetration |

| Weld Quality | High precision, clean welds with minimal spatter | Very precise with stable arc and excellent control |

| Operating Current Range | Low to medium (5-250 amps) | Medium to high (20-400 amps) |

| Automation Suitability | Widely used in automated and manual operations | Preferred for automated high-speed welding |

| Applications | Thin sections, aerospace, automotive, nuclear industries | Thicker materials, aerospace, electronics, medical devices |

| Cost | Lower equipment cost, moderate operating cost | Higher equipment cost, potentially lower operating cost due to efficiency |

Introduction to Gas Tungsten Arc Welding and Plasma Arc Welding

Gas Tungsten Arc Welding (GTAW) employs a non-consumable tungsten electrode to produce precise, high-quality welds, primarily used in applications requiring strong, clean joints such as aerospace and piping. Plasma Arc Welding (PAW) utilizes a plasma torch to create a high-temperature arc confined within a fine plasma column, enabling deeper penetration and faster welding speeds. Both processes use inert gas shielding to protect the weld area from atmospheric contamination, but PAW offers enhanced arc stability and versatility for thicker materials.

Working Principles: GTAW vs. PAW

Gas Tungsten Arc Welding (GTAW) uses a non-consumable tungsten electrode to create an electric arc that melts the workpiece metals for welding, with shielding provided by an inert gas like argon. Plasma Arc Welding (PAW) also employs a tungsten electrode but concentrates the arc by forcing it through a fine-bore copper nozzle, generating a high-temperature, ionized plasma jet for deeper penetration and faster welding speeds. GTAW offers precise control suited for thin materials, while PAW's plasma constriction allows for higher energy density, enabling welds in thicker sections and more complex joint geometries.

Equipment and Setup Comparison

Gas tungsten arc welding (GTAW) equipment requires a non-consumable tungsten electrode, a shielding gas supply typically using argon or helium, and a power source capable of providing a steady DC or AC current. Plasma arc welding (PAW) equipment involves a more complex torch that integrates a constricted plasma arc and a pilot arc, requiring a higher precision power supply and gas flow control system to handle plasma gas and shielding gas separately. PAW setup demands precise alignment and cooling systems to manage the elevated temperatures and focused arc characteristics, making it more sophisticated compared to the simpler GTAW apparatus.

Electrode and Shielding Gas Differences

Gas tungsten arc welding (GTAW) uses a non-consumable tungsten electrode and typically argon or helium as the shielding gas to protect the weld area from atmospheric contamination. Plasma arc welding (PAW) also employs a non-consumable tungsten electrode but features a constricted plasma jet formed by ionized gas, often argon or a mixture of argon and hydrogen, providing higher energy density and enhanced penetration. The shielding gas in PAW consists of both a primary plasma gas and a secondary shielding gas, offering superior control over weld characteristics compared to the single shielding gas used in GTAW.

Precision and Control in Welding Processes

Gas tungsten arc welding (GTAW) offers superior precision and control due to its stable arc and low heat input, making it ideal for welding thin materials and intricate joints. Plasma arc welding (PAW) provides a more concentrated and hotter plasma jet, enhancing penetration and enabling faster welding speeds while maintaining fine control over weld bead geometry. Both processes excel in delivering high-quality welds, but GTAW is preferred for applications requiring meticulous detail and minimal distortion.

Weld Quality and Appearance

Gas tungsten arc welding (GTAW) produces highly precise, clean welds with excellent bead appearance and minimal spatter, making it ideal for critical and cosmetic applications. Plasma arc welding (PAW) offers deeper penetration and higher welding speeds but may result in a rougher weld surface and increased potential for oxidation without proper shielding. Both processes yield strong, high-quality welds, but GTAW is preferred where superior aesthetics and fine detail are paramount.

Material Compatibility and Applications

Gas tungsten arc welding (GTAW) excels in welding thin sections of stainless steel, aluminum, and copper alloys due to its precise heat control and minimal distortion. Plasma arc welding (PAW) offers higher energy density, enabling effective welding of thicker materials like titanium, nickel alloys, and superalloys with deeper penetration and faster welding speeds. While GTAW is commonly used in aerospace, automotive, and food processing industries for precision joints, PAW suits heavy-duty applications requiring robust welds in shipbuilding, nuclear, and power generation sectors.

Advantages of GTAW over PAW

Gas tungsten arc welding (GTAW) offers superior control over the welding process compared to plasma arc welding (PAW), enabling precise heat input and minimal distortion especially beneficial for thin materials. GTAW produces higher quality, cleaner welds with less spatter due to the inert tungsten electrode and stable arc, making it ideal for critical applications in aerospace and medical industries. The versatility of GTAW in welding various metals and alloys without the need for complex equipment enhances its practicality over PAW in detailed fabrication tasks.

Advantages of PAW over GTAW

Plasma arc welding (PAW) offers higher welding speed and deeper penetration compared to gas tungsten arc welding (GTAW), resulting in increased productivity and stronger joints. PAW provides superior arc stability and allows for better control of the heat input, minimizing distortion and improving weld quality. The process also supports both manual and automated operations, making it highly versatile across various industrial applications.

Conclusion: Choosing Between GTAW and PAW

Gas tungsten arc welding (GTAW) offers superior precision and control, making it ideal for thin materials and critical applications requiring high-quality welds. Plasma arc welding (PAW) provides higher welding speeds and deeper penetration, suitable for thicker materials and automated processes. Selecting between GTAW and PAW depends on factors like material thickness, production volume, and desired weld quality.

Gas tungsten arc welding Infographic

libterm.com

libterm.com