Buttress thread design features a unique profile with one side perpendicular to the thread axis and the other slanted, providing superior strength and load-bearing capacity. This thread type is commonly used in applications requiring high resistance to axial forces, such as in heavy machinery and hydraulic cylinders. Explore the rest of the article to understand how Buttress threads can enhance your mechanical projects.

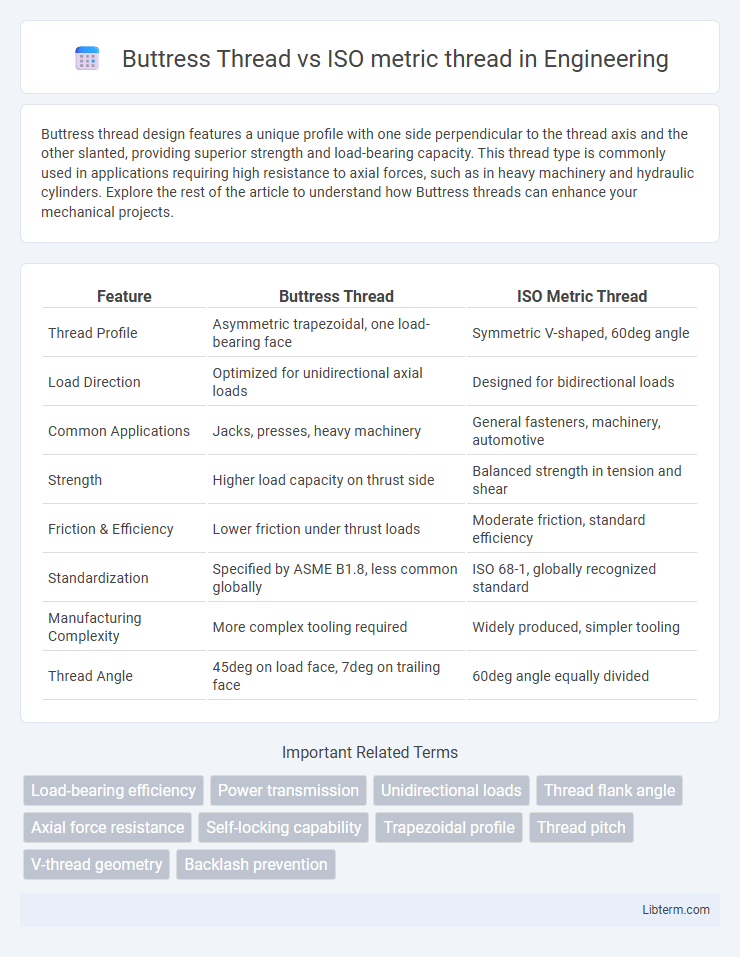

Table of Comparison

| Feature | Buttress Thread | ISO Metric Thread |

|---|---|---|

| Thread Profile | Asymmetric trapezoidal, one load-bearing face | Symmetric V-shaped, 60deg angle |

| Load Direction | Optimized for unidirectional axial loads | Designed for bidirectional loads |

| Common Applications | Jacks, presses, heavy machinery | General fasteners, machinery, automotive |

| Strength | Higher load capacity on thrust side | Balanced strength in tension and shear |

| Friction & Efficiency | Lower friction under thrust loads | Moderate friction, standard efficiency |

| Standardization | Specified by ASME B1.8, less common globally | ISO 68-1, globally recognized standard |

| Manufacturing Complexity | More complex tooling required | Widely produced, simpler tooling |

| Thread Angle | 45deg on load face, 7deg on trailing face | 60deg angle equally divided |

Introduction to Thread Types

Buttress threads feature a unique asymmetric profile designed for high axial load applications, offering superior strength on one flank and easier manufacturability compared to symmetrical threads. ISO metric threads, standardized internationally, exhibit a symmetrical V-shaped profile with a 60-degree angle optimized for general fastening purposes, ensuring compatibility and interchangeability across global machinery and equipment. The choice between buttress and ISO metric threads depends on application-specific requirements such as load direction, strength, and standardization needs.

Overview of Buttress Thread

Buttress threads feature an asymmetric profile with one face perpendicular to the axis and the other angled, providing high axial load resistance and strength primarily in one direction, ideal for applications such as heavy machinery and screw jacks. Compared to ISO metric threads, which have a symmetric 60-degree V-shaped profile designed for general-purpose fastening, buttress threads excel in transmitting power and withstanding stress in high-load scenarios. The unique geometry of buttress threads reduces shear failure and enhances durability under heavy thrust, making them preferred in industrial and hydraulic systems.

Overview of ISO Metric Thread

ISO metric threads follow international standards defined by the International Organization for Standardization (ISO), characterized by a 60-degree thread angle and standardized pitch and diameter sizes. These threads are widely used in general engineering due to their compatibility with a broad range of fasteners and equipment globally. The consistent geometry of ISO metric threads ensures reliable assembly, ease of manufacturing, and interchangeability across different industries.

Key Differences Between Buttress and ISO Metric Threads

Buttress threads feature an asymmetric profile with one face nearly perpendicular to the axis, providing high axial load capacity in one direction, commonly used in heavy machinery and screw jacks. ISO metric threads have a symmetrical V-shaped profile with a 60-degree flank angle, standardized for general-purpose fastening with uniform load distribution and ease of manufacturing. Key differences include load direction efficiency, thread angle geometry, and typical application environments, with buttress threads optimized for unilateral load-bearing and ISO metric threads suited for versatile, multi-directional fastening.

Mechanical Strength and Load Distribution

Buttress threads offer superior mechanical strength under high axial loads due to their asymmetric profile, which efficiently absorbs thrust in one direction, making them ideal for heavy-duty applications like jacks and presses. ISO metric threads have a symmetrical profile that provides uniform load distribution and balanced stress across the thread flanks, ensuring reliable performance in general fastening situations. The load distribution in buttress threads is concentrated on the load-bearing flank, enhancing strength, whereas ISO metric threads distribute load evenly but handle lower peak stresses.

Application Areas for Buttress Threads

Buttress threads excel in high-load applications such as hydraulic cylinders, heavy machinery, and aerospace components due to their asymmetric profile designed to withstand axial thrust primarily in one direction. These threads are ideal for transmitting power efficiently where substantial force is applied, unlike ISO metric threads which are more commonly used for general-purpose fastening across automotive, construction, and machinery industries. The unique geometry of buttress threads reduces shear stress and improves load-bearing capacity in situations requiring high strength and durability under axial loads.

Application Areas for ISO Metric Threads

ISO metric threads are widely used in machinery, automotive, and consumer electronics due to their standardized dimensions and versatility for fastening components. Their application areas include assembly of engines, fasteners in construction equipment, and precision instruments requiring reliable and repeatable threading. These threads offer consistent mechanical strength and compatibility in global manufacturing, making them ideal for general-purpose fastening where interchangeability is critical.

Manufacturing and Machining Considerations

Buttress threads offer superior strength and load-bearing capacity in one direction, making them ideal for heavy-duty applications requiring high axial loads, while ISO metric threads provide standardized dimensions suited for general-purpose fastening with easier interchangeability. Manufacturing buttress threads demands specialized tooling and precise control to produce the asymmetric profile, increasing complexity and cost compared to the simpler, symmetric ISO metric threads, which benefit from widely available cutting tools and established machining processes. Machining ISO metric threads typically involves conventional threading operations with standard pitches and profiles, whereas buttress threads require customized thread cutting or rolling techniques to achieve their unique geometry, influencing cycle times and tooling wear.

Advantages and Disadvantages Comparison

Buttress threads offer superior load-bearing capacity and resistance to axial forces, making them ideal for high-stress applications such as heavy machinery and hydraulic systems. ISO metric threads provide standardized dimensions and compatibility across global industries, facilitating mass production and ease of maintenance but may lack the same strength under extreme loads. While buttress threads excel in durability and force distribution, ISO metric threads benefit from widespread availability and interchangeability, posing limitations in applications requiring maximum load resistance.

Choosing the Right Thread for Your Application

Choosing the right thread for your application depends on load direction, sealing needs, and manufacturing ease. Buttress threads excel in high axial load scenarios, offering superior strength and efficient load transfer, making them ideal for heavy machinery and oilfield equipment. ISO metric threads provide standardized dimensions and better compatibility, suited for general-purpose fasteners requiring easy assembly and maintenance.

Buttress Thread Infographic

libterm.com

libterm.com