Mercury-wetted relays provide ultra-low contact resistance and high reliability due to their liquid metal contacts, making them ideal for precision switching applications. These relays minimize contact degradation and arcing, ensuring consistent performance over extensive cycles. Discover how your projects can benefit from the unique advantages of mercury-wetted relays by exploring the rest of this article.

Table of Comparison

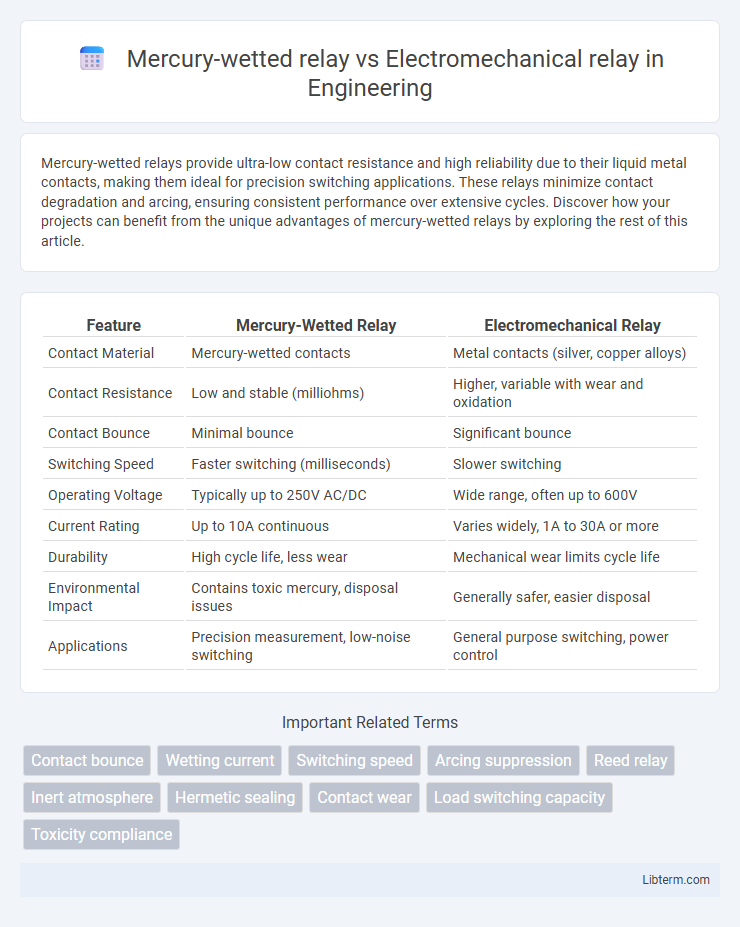

| Feature | Mercury-Wetted Relay | Electromechanical Relay |

|---|---|---|

| Contact Material | Mercury-wetted contacts | Metal contacts (silver, copper alloys) |

| Contact Resistance | Low and stable (milliohms) | Higher, variable with wear and oxidation |

| Contact Bounce | Minimal bounce | Significant bounce |

| Switching Speed | Faster switching (milliseconds) | Slower switching |

| Operating Voltage | Typically up to 250V AC/DC | Wide range, often up to 600V |

| Current Rating | Up to 10A continuous | Varies widely, 1A to 30A or more |

| Durability | High cycle life, less wear | Mechanical wear limits cycle life |

| Environmental Impact | Contains toxic mercury, disposal issues | Generally safer, easier disposal |

| Applications | Precision measurement, low-noise switching | General purpose switching, power control |

Introduction to Mercury-Wetted and Electromechanical Relays

Mercury-wetted relays use a small amount of mercury to create a low-resistance, metal-to-metal contact that ensures fast switching and minimal contact bounce, making them suitable for high-reliability applications. Electromechanical relays rely on a mechanical armature to open or close contacts, which can introduce contact wear and electrical noise over time, impacting performance and longevity. The choice between these relays involves considerations of switching speed, contact stability, and application-specific durability requirements.

Working Principle of Mercury-Wetted Relays

Mercury-wetted relays operate by using a small pool of liquid mercury that creates a low-resistance electrical contact when the relay coil energizes and moves a wetted armature to close the circuit, ensuring rapid and reliable switching with minimal contact bounce. This liquid metal contact provides superior conductivity and significantly decreased contact wear compared to traditional electromechanical relays, which rely on physical metal contacts clamping together under mechanical force. The mercury-wetted design enhances switching speed, reduces arcing, and extends relay lifespan in applications requiring high cycling endurance and precision.

Operating Mechanism of Electromechanical Relays

Electromechanical relays operate using an electromagnetic coil that, when energized, creates a magnetic field to attract a movable armature, closing or opening the contact points to control the circuit. Mercury-wetted relays, in contrast, use a small amount of mercury to create a low-resistance wet contact that minimizes contact bounce and erosion, enhancing switching performance. The mechanical movement in electromechanical relays involves physical contact separation and engagement, which can result in higher contact resistance and wear over time compared to the liquid metal interface of mercury-wetted relays.

Key Material Differences

Mercury-wetted relays use a pool of liquid mercury to create a low-resistance, highly reliable contact closure, whereas electromechanical relays rely on physical metal contacts that mechanically close or open the circuit. The mercury contacts offer superior resistance to contact wear, oxidation, and arcing compared to the silver or copper alloy contacts commonly found in electromechanical relays. This material difference results in longer lifespan, faster switching, and lower contact bounce for mercury-wetted relays, especially in applications requiring high-frequency switching or stable low-resistance contacts.

Switching Speed Comparison

Mercury-wetted relays exhibit significantly faster switching speeds, typically in the range of milliseconds, compared to conventional electromechanical relays which switch in tens of milliseconds. The low contact resistance and reduced bounce in mercury-wetted relays enhance their response time, enabling precise and rapid switching in high-speed applications. Electromechanical relays, due to mechanical movement and contact bounce, have slower switching characteristics that limit their use in fast-switching circuits.

Contact Life and Reliability

Mercury-wetted relays offer significantly longer contact life and higher reliability than traditional electromechanical relays due to their mercury-coated contacts, which reduce contact resistance and prevent oxidation. These relays typically achieve millions of switching cycles with minimal contact wear, making them ideal for applications requiring consistent performance over extended periods. In contrast, electromechanical relays experience contact degradation and increased resistance over time, leading to shorter operational lifespans and higher failure rates in demanding environments.

Signal Integrity and Contact Bounce

Mercury-wetted relays offer superior signal integrity compared to electromechanical relays due to their low contact resistance and minimal contact bounce, resulting in cleaner, more reliable signal transmission. The mercury-wetted contacts reduce arcing and contact degradation, significantly lowering contact bounce times typically observed in conventional electromechanical relays. This makes mercury-wetted relays preferable in high-precision applications where signal clarity and fast, stable switching are critical.

Safety and Environmental Considerations

Mercury-wetted relays offer superior contact reliability with minimal arcing, significantly reducing the risk of contact welding and fire hazards, enhancing safety in critical applications. However, the presence of mercury poses environmental and health risks due to its toxicity and potential for contamination if the relay is damaged or improperly disposed of. Electromechanical relays avoid mercury-related hazards but may experience higher contact wear and increased risk of sparks, requiring additional protective measures to ensure safe operation.

Typical Applications and Use Cases

Mercury-wetted relays are commonly used in timing circuits, precision measurement instruments, and low-level signal switching due to their fast, bounce-free contacts and reliable performance in sensitive electronic applications. Electromechanical relays find extensive use in general-purpose power switching, industrial automation, motor control, and household appliances where robust and cost-effective switching solutions are required. Both relay types serve distinct roles based on their switching speed, contact reliability, and application-specific requirements in controlling electrical circuits.

Choosing the Right Relay for Your Project

Mercury-wetted relays offer low contact resistance and fast switching speeds, making them ideal for precision instrumentation and high-frequency applications, whereas electromechanical relays provide robust mechanical isolation and are suitable for general-purpose switching with higher current loads. Consider the operating environment; mercury-wetted relays require careful handling due to mercury content, while electromechanical relays can endure harsher conditions and have longer mechanical life cycles. Selecting the right relay involves evaluating factors such as load type, switching speed, environmental impact, and reliability requirements to ensure optimal performance in your project.

Mercury-wetted relay Infographic

libterm.com

libterm.com