Mohs hardness measures a mineral's resistance to scratching, ranking materials on a scale from 1 (talc) to 10 (diamond). This scale helps you identify gemstones and determine their durability for various uses. Dive into the rest of the article to explore how Mohs hardness impacts practical applications and material selection.

Table of Comparison

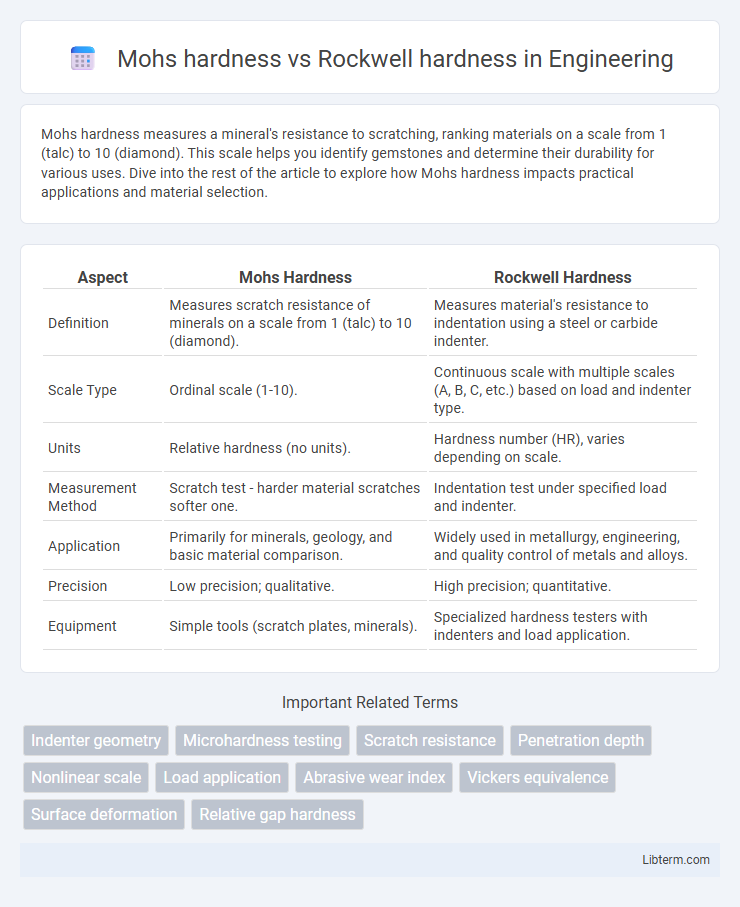

| Aspect | Mohs Hardness | Rockwell Hardness |

|---|---|---|

| Definition | Measures scratch resistance of minerals on a scale from 1 (talc) to 10 (diamond). | Measures material's resistance to indentation using a steel or carbide indenter. |

| Scale Type | Ordinal scale (1-10). | Continuous scale with multiple scales (A, B, C, etc.) based on load and indenter type. |

| Units | Relative hardness (no units). | Hardness number (HR), varies depending on scale. |

| Measurement Method | Scratch test - harder material scratches softer one. | Indentation test under specified load and indenter. |

| Application | Primarily for minerals, geology, and basic material comparison. | Widely used in metallurgy, engineering, and quality control of metals and alloys. |

| Precision | Low precision; qualitative. | High precision; quantitative. |

| Equipment | Simple tools (scratch plates, minerals). | Specialized hardness testers with indenters and load application. |

Introduction to Hardness Testing

Hardness testing measures a material's resistance to deformation, with Mohs hardness assessing scratch resistance on a scale from 1 (talc) to 10 (diamond), ideal for minerals. Rockwell hardness quantifies resistance to indentation using a standardized load and indenter, providing precise numerical values for metals and alloys. These tests are fundamental in materials science for selecting appropriate materials based on durability and wear resistance.

Understanding Mohs Hardness Scale

Mohs hardness scale measures a mineral's resistance to scratching, ranking materials from 1 (talc) to 10 (diamond) based on their ability to scratch others. It provides a qualitative assessment widely used in geology and mineralogy to identify minerals quickly and effectively. Unlike the Rockwell hardness scale, which quantifies a material's resistance to indentation with specific numerical values, the Mohs scale emphasizes relative hardness through comparative scratch tests.

Overview of Rockwell Hardness Testing

Rockwell hardness testing measures a material's resistance to penetration by applying a fixed load with a specified indenter, producing a direct hardness value based on depth of indentation. Unlike the Mohs hardness scale, which ranks minerals by scratch resistance from 1 to 10, Rockwell testing provides precise numerical hardness levels for metals and alloys using various scales (e.g., A, B, C). This method enables rapid, standardized assessments of material hardness essential for quality control and material selection in manufacturing and engineering applications.

Key Differences Between Mohs and Rockwell Scales

Mohs hardness scale measures scratch resistance on a 1 to 10 scale, ranking minerals from talc to diamond, emphasizing qualitative surface hardness. Rockwell hardness scale quantifies material hardness using indentation depth under a specific load, providing precise numeric values ideal for metals and alloys. Mohs is simple and comparative for minerals, while Rockwell offers accurate, reproducible results crucial for engineering and manufacturing applications.

Testing Methods: Mohs vs Rockwell

Mohs hardness testing uses a scratch method to determine mineral resistance, ranking materials on a scale from 1 (talc) to 10 (diamond) based on their ability to scratch or be scratched by reference minerals. Rockwell hardness testing employs an indentation method, measuring the depth of penetration under a fixed load with a hardened steel or carbide ball or diamond cone, providing a numerical hardness value on various Rockwell scales (e.g., A, B, C). While Mohs emphasizes qualitative scratch comparisons ideal for minerals, Rockwell offers precise quantitative measurements suited for metals and engineered materials.

Accuracy and Precision Comparison

Mohs hardness scale ranks minerals based on scratch resistance, providing a qualitative measure with limited precision, suitable for field identification but prone to subjective interpretation. Rockwell hardness test yields an accurate and precise numeric value by measuring indentation depth under a specific load, offering repeatable results ideal for engineering and quality control. Compared to Mohs, Rockwell hardness delivers higher accuracy and precision due to standardized testing protocols and calibration.

Applications in Industry and Research

Mohs hardness scale is widely used in mineralogy and geology to quickly identify minerals based on scratch resistance, while Rockwell hardness is preferred in metallurgy and manufacturing for precise measurement of metal hardness via indentation depth. Industrial applications favor Rockwell hardness for quality control of alloys, steels, and heat-treated materials due to its quantitative accuracy and reproducibility. Research environments utilize Mohs scale for preliminary material characterization and Rockwell hardness for detailed assessment of mechanical properties in engineering and materials science studies.

Advantages and Limitations of Each Scale

Mohs hardness scale offers simplicity and ease of use by ranking minerals from 1 to 10 based on scratch resistance, making it practical for quick field identification but lacks precision for industrial applications. Rockwell hardness scale provides a more accurate and quantitative measurement of material hardness through penetration testing, enabling consistent comparisons across metals and alloys, although it requires specialized equipment and is less intuitive for non-technical users. While Mohs is ideal for rapid assessment of mineral hardness, Rockwell excels in detailed material specification and quality control in manufacturing processes.

Choosing the Right Hardness Test

Choosing the right hardness test depends on the material type and the required precision; Mohs hardness is ideal for quick, comparative mineral identification based on scratch resistance, while Rockwell hardness provides detailed, quantitative measurements for metals and industrial materials using indentation depth. Mohs scale ranges from 1 to 10, emphasizing relative hardness, whereas Rockwell hardness offers numerical values across various scales (e.g., A, B, C) tailored to specific materials and testing loads. Selecting between them requires considering application demands, material properties, and whether qualitative or quantitative data better supports engineering decisions.

Summary: Mohs Hardness vs Rockwell Hardness

Mohs hardness measures the scratch resistance of minerals on a scale from 1 to 10, primarily used for identifying mineral properties. Rockwell hardness quantifies a material's resistance to indentation, providing precise numerical values for metals and alloys through different scales such as A, B, and C. While Mohs hardness is qualitative and simple, Rockwell hardness offers quantitative, reproducible results essential for engineering and industrial applications.

Mohs hardness Infographic

libterm.com

libterm.com