Counterboring creates a flat-bottomed hole that allows fastener heads to sit flush or below the surface, improving both appearance and structural integrity. This machining process is essential for precise assembly in various industries, from automotive to aerospace, where alignment and load distribution are critical. Explore the rest of the article to understand how counterboring can enhance your projects and the techniques involved.

Table of Comparison

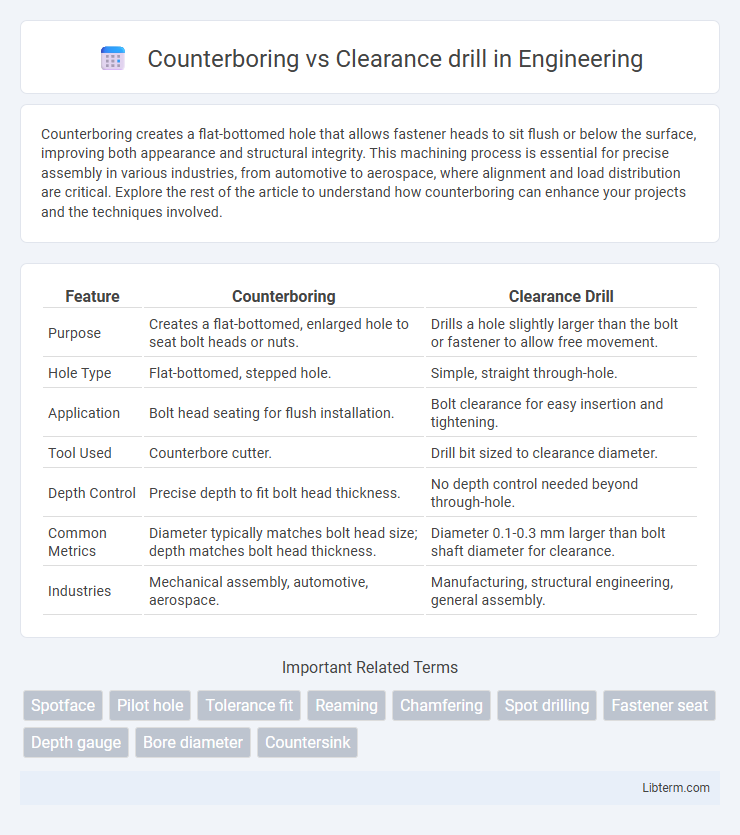

| Feature | Counterboring | Clearance Drill |

|---|---|---|

| Purpose | Creates a flat-bottomed, enlarged hole to seat bolt heads or nuts. | Drills a hole slightly larger than the bolt or fastener to allow free movement. |

| Hole Type | Flat-bottomed, stepped hole. | Simple, straight through-hole. |

| Application | Bolt head seating for flush installation. | Bolt clearance for easy insertion and tightening. |

| Tool Used | Counterbore cutter. | Drill bit sized to clearance diameter. |

| Depth Control | Precise depth to fit bolt head thickness. | No depth control needed beyond through-hole. |

| Common Metrics | Diameter typically matches bolt head size; depth matches bolt head thickness. | Diameter 0.1-0.3 mm larger than bolt shaft diameter for clearance. |

| Industries | Mechanical assembly, automotive, aerospace. | Manufacturing, structural engineering, general assembly. |

Introduction to Counterboring and Clearance Drilling

Counterboring creates a flat-bottomed enlargement at the top of a hole to accommodate fastener heads, ensuring a flush surface for bolts or screws. Clearance drilling involves making a hole slightly larger than the fastener to allow free movement and proper alignment during assembly. Both techniques are critical in mechanical engineering and manufacturing for securing components with precision and ease.

What is Counterboring?

Counterboring is a machining process that enlarges a portion of an existing hole to create a flat-bottomed recess, allowing fastener heads, such as socket head capscrews, to sit flush with or below the surface. This technique differs from clearance drilling, where the hole diameter is increased solely to allow a fastener to pass through without threading or seating. Counterboring ensures proper seating, improved load distribution, and an aesthetically smooth surface finish in mechanical assemblies.

What is a Clearance Drill?

A clearance drill is a hole drilled to a diameter slightly larger than the fastener's outer diameter, allowing the bolt or screw to pass through freely without threading into the material. This technique ensures proper alignment and prevents friction or damage during assembly by providing clearance for the fastener. Clearance drills are essential in mechanical design for securing parts with bolts, nuts, or screws where threading is required only on the receiving end.

Key Differences Between Counterboring and Clearance Drilling

Counterboring creates a flat-bottomed hole larger in diameter than the main hole, allowing fastener heads to sit flush or below the surface, whereas clearance drilling produces a hole just slightly larger than the fastener shaft for free passage. Counterbore holes typically have a precise diameter and depth to accommodate bolt heads or nuts, while clearance drill holes prioritize tolerance to prevent threading interference. The primary distinction lies in functional purpose: counterboring enables recessed seating of hardware, while clearance drilling provides unobstructed shaft clearance during assembly.

Applications of Counterboring in Manufacturing

Counterboring is widely utilized in manufacturing for creating flat-bottomed holes that allow fastener heads to sit flush or below the surface, ensuring a clean and secure assembly. It is essential in applications such as machinery assembly, automotive parts, and aerospace components where precise alignment and load distribution are critical. This method improves joint strength and aesthetic appearance by accommodating socket head cap screws or bolt heads in metal and plastic parts.

Uses of Clearance Drills in Engineering

Clearance drills are essential in engineering for creating holes that allow fasteners like bolts or screws to pass through without threading into the material. These drills ensure precise alignment and adequate space for shafts, pins, or bolts, enabling accurate assembly and easy disassembly of mechanical components. They are commonly used in applications requiring non-threaded holes for pins, dowels, or alignment and in preparing holes for subsequent tapping or threading operations.

Tool Design and Geometry: Counterbore vs Clearance Drill

Counterbore tools feature a stepped design with a larger diameter cutting head followed by a smaller pilot drill, enabling precise recesses for bolt heads or fasteners. Clearance drills consist of a single cutting edge with a uniform diameter designed to create holes that allow fastener shafts to pass through without interference. The geometry of counterboring tools ensures accurate seating depth and smooth surface finish, while clearance drills prioritize hole accuracy and smooth entry for fasteners.

Advantages and Disadvantages of Counterboring

Counterboring offers the advantage of creating a flat-bottomed hole that allows fasteners to sit flush or below the surface, providing a clean and secure finish suitable for precision applications. This method improves load distribution and enhances joint stability but requires more complex tooling and longer machining time compared to clearance drilling. However, the increased manufacturing cost and potential for misalignment during setup are notable disadvantages when compared to simpler clearance drills.

Pros and Cons of Clearance Drilling

Clearance drilling offers the advantage of creating a hole slightly larger than the fastener, allowing for precise alignment and easy assembly, which reduces stress on the materials being joined. However, this method can compromise joint strength since the fastener does not tightly grip the surrounding material, potentially leading to loosening under vibration or dynamic loads. Clearance drilling is also less suitable for applications requiring high load-bearing capacity or where a flush finish is necessary, unlike counterboring which provides a seat for fastener heads.

Choosing the Right Technique: Counterboring or Clearance Drill?

Choosing between counterboring and clearance drilling depends on the specific requirements of your fastening assembly. Counterboring is ideal for applications needing a bolt or screw head to sit flush or below the surface, providing a clean and secure fit, while clearance drilling is used to create a hole that allows fasteners to pass through freely without threading engagement. Understanding the material thickness, fastener type, and load distribution will guide the selection of the proper technique, ensuring optimal mechanical strength and aesthetic finish.

Counterboring Infographic

libterm.com

libterm.com