Gear drives transmit mechanical power efficiently between shafts, enabling precise speed and torque control in machinery. Their design ensures durability and reduces slippage, making them essential in automotive, industrial, and robotics applications. Explore the rest of the article to understand how gear drives optimize your equipment's performance.

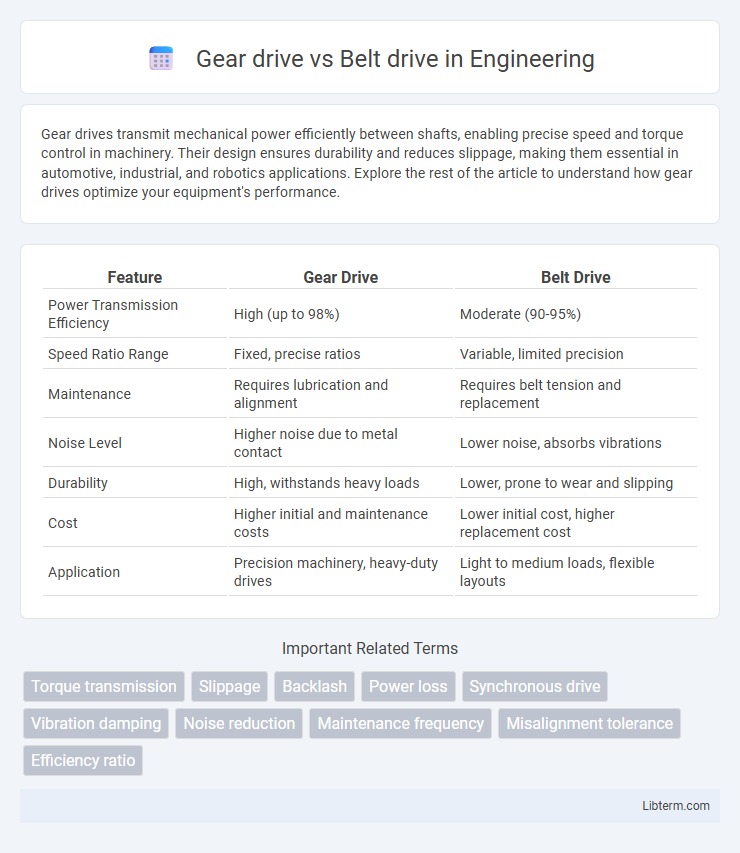

Table of Comparison

| Feature | Gear Drive | Belt Drive |

|---|---|---|

| Power Transmission Efficiency | High (up to 98%) | Moderate (90-95%) |

| Speed Ratio Range | Fixed, precise ratios | Variable, limited precision |

| Maintenance | Requires lubrication and alignment | Requires belt tension and replacement |

| Noise Level | Higher noise due to metal contact | Lower noise, absorbs vibrations |

| Durability | High, withstands heavy loads | Lower, prone to wear and slipping |

| Cost | Higher initial and maintenance costs | Lower initial cost, higher replacement cost |

| Application | Precision machinery, heavy-duty drives | Light to medium loads, flexible layouts |

Introduction to Gear Drive and Belt Drive

Gear drives transmit power through meshing gears, offering high torque and precise speed control vital for heavy machinery and automotive applications. Belt drives use flexible belts running over pulleys, providing smooth, quiet operation suited for variable speed and light to medium load transmissions. Both systems serve essential roles in mechanical power transmission, with gear drives excelling in durability and belt drives favored for simplicity and shock absorption.

Basic Working Principles

Gear drives transmit torque through meshing teeth on gears, ensuring precise speed ratios and high power transmission efficiency with minimal slip. Belt drives use a flexible belt looped over pulleys to transfer motion and power, allowing for smooth, quiet operation and accommodating slight misalignments. Gear drives are typically preferred for high-torque applications requiring accuracy, while belt drives excel in moderate power scenarios with the need for shock absorption.

Key Differences Between Gear Drive and Belt Drive

Gear drives provide positive, non-slip power transmission with high torque capacity and precise speed ratios, making them ideal for heavy-duty applications requiring accuracy. Belt drives offer flexible, quieter operation with shock absorption and easier maintenance but may slip under heavy loads and provide less precise speed control. Gear drives typically require lubrication and have higher manufacturing complexity, while belt drives are simpler, cost-effective, and suited for moderate power transmission with variable center distances.

Efficiency and Power Transmission

Gear drives exhibit higher efficiency and more reliable power transmission due to direct metal-to-metal contact, minimizing slippage and energy losses. Belt drives, while offering flexibility and shock absorption, typically experience lower efficiency because of belt slip and stretch under load, leading to energy dissipation. In applications demanding precise speed ratios and consistent torque, gear drives outperform belt drives by maintaining stable power delivery and reduced maintenance requirements.

Maintenance Requirements

Gear drives require regular lubrication and inspection for wear, as metal components can experience friction and fatigue over time. Belt drives demand frequent tension adjustments and periodic replacement of belts due to stretching and wear. Gear drives typically have higher maintenance costs compared to belt drives, but offer greater durability and load capacity.

Applications in Industry

Gear drives are widely used in heavy-duty industrial applications requiring precise speed control and high torque transmission, such as in manufacturing machinery, conveyors, and automotive systems. Belt drives are preferred in applications where flexibility, shock absorption, and quieter operation are beneficial, including packaging equipment, HVAC systems, and agricultural machinery. Industries prioritize gear drives for power transmission efficiency and durability, while belt drives offer cost-effective maintenance and adaptability to misalignment.

Noise and Vibration Characteristics

Gear drives typically produce higher noise and vibration levels due to the meshing of gear teeth, which can generate impact forces and harmonic vibrations. Belt drives offer quieter operation and reduced vibration because the belts absorb shock and provide smoother power transmission with less metal-on-metal contact. Noise and vibration reduction in belt drives makes them ideal for applications requiring quieter environments and smoother mechanical performance.

Cost Considerations

Gear drives generally involve higher initial costs due to precision manufacturing, materials, and tighter tolerances, resulting in longer-lasting components with lower maintenance expenses. Belt drives offer a more economical upfront investment, often suited for lighter loads and simpler applications but may incur higher ongoing costs due to belt replacement and potential slippage. Evaluating total cost of ownership, including durability, efficiency, and maintenance frequency, is crucial when choosing between gear drive and belt drive systems.

Advantages and Disadvantages

Gear drives offer precise power transmission with high torque capacity and minimal slippage, making them ideal for heavy-duty applications. However, they can be noisy, require lubrication, and involve higher manufacturing costs compared to belt drives. Belt drives provide quieter operation, flexibility in load handling, and easier maintenance but suffer from lower efficiency due to potential slippage and limited torque transmission capability.

Choosing the Right Drive System

Selecting between gear drive and belt drive depends on factors such as power transmission efficiency, maintenance needs, and operational conditions. Gear drives offer precise motion control, high torque capacity, and durability ideal for heavy-duty applications requiring minimal slip. Belt drives provide quieter operation, flexibility, and cost-effectiveness suited for moderate loads and environments where vibration dampening is important.

Gear drive Infographic

libterm.com

libterm.com