Mixed-flow fans combine the characteristics of axial and centrifugal fans to deliver efficient airflow with moderate pressure in a compact design. Their versatile performance makes them ideal for HVAC systems, cooling applications, and ventilation where space is limited but reliable air movement is essential. Explore the full article to understand how mixed-flow technology can enhance your ventilation solutions.

Table of Comparison

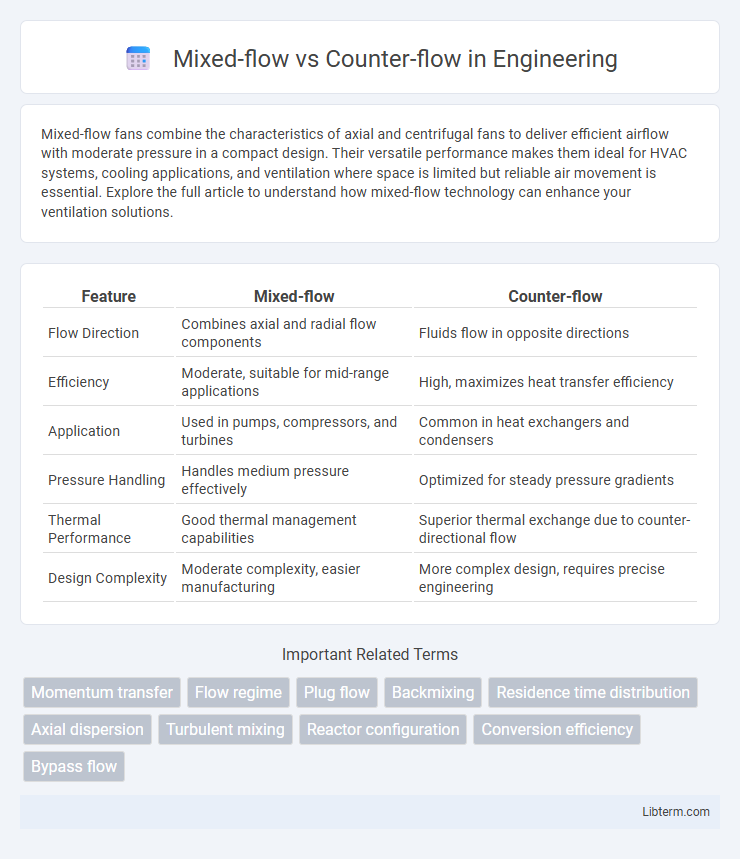

| Feature | Mixed-flow | Counter-flow |

|---|---|---|

| Flow Direction | Combines axial and radial flow components | Fluids flow in opposite directions |

| Efficiency | Moderate, suitable for mid-range applications | High, maximizes heat transfer efficiency |

| Application | Used in pumps, compressors, and turbines | Common in heat exchangers and condensers |

| Pressure Handling | Handles medium pressure effectively | Optimized for steady pressure gradients |

| Thermal Performance | Good thermal management capabilities | Superior thermal exchange due to counter-directional flow |

| Design Complexity | Moderate complexity, easier manufacturing | More complex design, requires precise engineering |

Introduction to Flow Patterns in Heat Exchangers

Mixed-flow and counter-flow are two fundamental heat exchanger flow patterns influencing thermal performance and efficiency. Mixed-flow involves a combination of parallel and perpendicular fluid movements, promoting moderate heat transfer rates and enhanced turbulence. Counter-flow aligns fluids moving in opposite directions, maximizing temperature gradients and achieving superior heat transfer efficiency.

Defining Mixed-flow and Counter-flow Systems

Mixed-flow systems combine airflow patterns where air streams intersect at varying angles, promoting uniform mixing and balanced temperature distribution. Counter-flow systems feature fluids moving in opposite directions, maximizing heat exchange efficiency by maintaining a consistent temperature gradient. Understanding the fundamental design differences helps optimize performance in HVAC, heat exchangers, and industrial processes.

Key Differences Between Mixed-flow and Counter-flow

Mixed-flow heat exchangers combine axial and radial flow patterns, promoting moderate heat transfer efficiency with less complex design and lower pressure drop. Counter-flow heat exchangers feature fluid streams moving in opposite directions, maximizing temperature gradient and heat transfer efficiency, resulting in better thermal performance. Key differences include flow arrangement impact on heat transfer rate, pressure drop, and application suitability, where counter-flow excels in efficiency while mixed-flow offers simpler construction and cost-effectiveness.

Thermal Efficiency Comparison

Mixed-flow heat exchangers typically exhibit lower thermal efficiency compared to counter-flow designs due to less effective temperature gradients. Counter-flow configurations maintain a higher average temperature difference between fluids along the exchanger length, maximizing heat transfer rates. Studies show counter-flow heat exchangers can achieve thermal efficiencies up to 30% greater than mixed-flow units in comparable conditions.

Pressure Drop Considerations

Mixed-flow heat exchangers typically exhibit higher pressure drops due to turbulence and complex flow paths, which can increase energy consumption in pumping systems. In contrast, counter-flow designs maintain lower pressure drops by enabling streamlined, opposite-direction flow, enhancing fluid velocity uniformity and minimizing friction losses. Optimizing pressure drop in heat exchanger selection is critical for maximizing thermal efficiency while reducing operational costs and system wear.

Design Applications and Suitability

Mixed-flow fans offer versatile design applications with moderate pressure capabilities, making them suitable for HVAC systems and industrial ventilation where space constraints and noise reduction are important. Counter-flow heat exchangers excel in thermal efficiency by allowing fluids to flow in opposite directions, widely used in energy recovery ventilation, chemical processing, and refrigeration systems requiring maximum heat transfer. Selection depends on the need for airflow control versus heat exchange efficiency, with mixed-flow designs favored for balanced airflow and pressure, while counter-flow setups prioritize optimal thermal performance.

Advantages of Mixed-flow Heat Exchangers

Mixed-flow heat exchangers offer higher heat transfer efficiency by combining the benefits of both parallel-flow and counter-flow designs, enhancing thermal performance in compact spaces. They provide improved temperature uniformity and reduced thermal stress, extending equipment lifespan and reliability. These advantages make mixed-flow heat exchangers ideal for applications requiring balanced temperature gradients and robust operation under variable conditions.

Benefits of Counter-flow Heat Exchangers

Counter-flow heat exchangers offer superior thermal efficiency compared to mixed-flow designs, enabling higher heat transfer rates by maintaining a greater temperature gradient along the heat exchanger length. They minimize energy consumption and improve process performance in applications like HVAC systems, power plants, and chemical processing. Enhanced temperature control and compact design benefits make counter-flow heat exchangers ideal for maximizing heat recovery and reducing operational costs.

Typical Industries and Use Cases

Mixed-flow heat exchangers are commonly used in industries such as chemical processing, HVAC, and automotive cooling systems where moderate thermal performance and compact design are essential for fluids with varying flow rates. Counter-flow heat exchangers are preferred in power plants, oil refining, and food processing industries due to their superior thermal efficiency and ability to maintain high temperature gradients between incoming and outgoing fluids. Use cases for mixed-flow include cooling of lubricants and air compression systems, whereas counter-flow designs are ideal for condensers and boilers requiring maximum heat transfer.

Choosing the Right Flow Configuration

Selecting the appropriate flow configuration between mixed-flow and counter-flow heat exchangers depends on efficiency requirements and application type. Counter-flow designs offer superior heat transfer by maintaining a higher temperature gradient along the exchanger length, making them ideal for processes requiring maximum thermal efficiency. Mixed-flow configurations provide balanced performance with simpler construction, suitable for applications where moderate heat transfer and cost-effectiveness are priorities.

Mixed-flow Infographic

libterm.com

libterm.com