Takt time measures the rate at which products must be completed to meet customer demand, aligning production speed with sales pace for optimal efficiency. By calculating takt time, companies can streamline workflows, reduce waste, and balance workloads across the production line. Discover how mastering takt time can transform your operations by reading the full article.

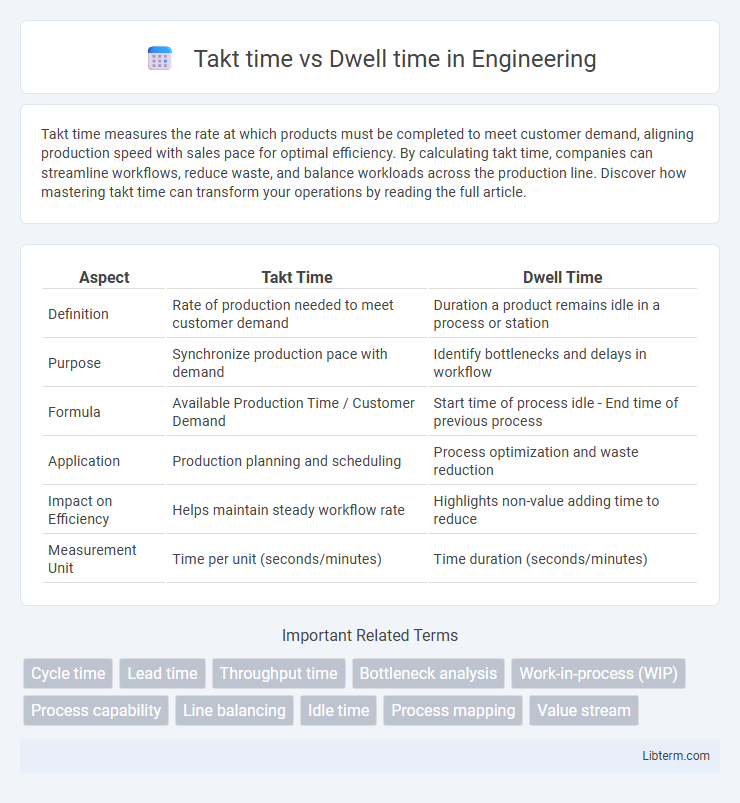

Table of Comparison

| Aspect | Takt Time | Dwell Time |

|---|---|---|

| Definition | Rate of production needed to meet customer demand | Duration a product remains idle in a process or station |

| Purpose | Synchronize production pace with demand | Identify bottlenecks and delays in workflow |

| Formula | Available Production Time / Customer Demand | Start time of process idle - End time of previous process |

| Application | Production planning and scheduling | Process optimization and waste reduction |

| Impact on Efficiency | Helps maintain steady workflow rate | Highlights non-value adding time to reduce |

| Measurement Unit | Time per unit (seconds/minutes) | Time duration (seconds/minutes) |

Understanding Takt Time: Definition and Importance

Takt time represents the maximum allowable time to produce a product in order to meet customer demand, calculated by dividing available production time by customer demand. It is essential for synchronizing production pace, minimizing waste, and ensuring efficient resource utilization in lean manufacturing. Understanding takt time enables manufacturers to balance workload, optimize throughput, and improve overall operational efficiency.

Defining Dwell Time in Manufacturing Processes

Dwell time in manufacturing processes refers to the period a workpiece remains in a particular stage or machine without active processing, often for curing, cooling, or inspection purposes. This interval is critical for ensuring product quality and process stability, directly impacting cycle efficiency and throughput. Distinct from takt time, which defines the rate of production to meet customer demand, dwell time emphasizes the necessary pause for optimal operational outcomes.

Key Differences Between Takt Time and Dwell Time

Takt time measures the pace at which a product must be completed to meet customer demand, calculated by dividing available production time by customer demand units. Dwell time represents the total duration a component or workpiece remains in a specific process step or location without active processing. The key differences lie in takt time being a production rate metric aimed at synchronization, whereas dwell time reflects idle or waiting periods within the workflow, impacting overall cycle efficiency.

The Role of Takt Time in Lean Manufacturing

Takt time plays a crucial role in Lean Manufacturing by establishing the pace at which products must be completed to meet customer demand, ensuring a smooth production flow without overproduction. Unlike dwell time, which measures the idle period a product or workstation remains inactive, takt time drives process synchronization and waste reduction by aligning production speed with demand rate. Implementing takt time enables manufacturers to identify bottlenecks quickly and balance workload across workstations, enhancing overall operational efficiency.

How Dwell Time Impacts Production Efficiency

Dwell time, the period a product or component remains idle between process steps, directly affects production efficiency by creating bottlenecks and reducing overall throughput. Extended dwell time increases lead time and inventory holding costs, disrupting the smooth flow of manufacturing operations. Minimizing dwell time aligns production pace with takt time, ensuring resources are utilized effectively and customer demand is met consistently.

Calculating Takt Time: Step-by-Step Guide

Takt time is calculated by dividing the available production time by customer demand within that period, providing a precise rhythm for manufacturing processes. To calculate takt time, determine the total available work time per shift (in seconds or minutes) and divide it by the number of units required by customers during that shift. This calculation ensures production aligns with demand, minimizing waste and optimizing workflow efficiency in lean manufacturing environments.

Methods to Measure and Reduce Dwell Time

Takt time represents the ideal production pace to meet customer demand, calculated by dividing available production time by customer demand, while dwell time refers to the period materials or work-in-progress remain idle during the production process. Measuring dwell time involves using time tracking tools, process mapping, and data analytics to identify bottlenecks and idle periods within workflows. Reducing dwell time can be achieved by implementing just-in-time inventory practices, optimizing material handling routes, and utilizing lean manufacturing techniques such as value stream mapping to streamline operations and minimize delays.

Takt Time vs Dwell Time: Real-World Examples

Takt time measures the ideal production pace to meet customer demand, while dwell time refers to the actual wait or idle time within a process. In automotive assembly lines, a takt time of 60 seconds per unit ensures synchronized workflow, whereas dwell time arises during machine setup or material handling delays, causing inefficiencies. Warehousing operations use takt time to maintain order processing rates, but excessive dwell time occurs in storage, impacting overall throughput and delivery speed.

Optimizing Workflow by Balancing Takt and Dwell Time

Balancing takt time and dwell time is crucial for optimizing workflow efficiency in manufacturing and service processes. Takt time, defined as the rate at which products must be completed to meet customer demand, should align closely with dwell time, which is the duration work-in-progress items spend waiting before the next process step. Minimizing dwell time without sacrificing takt time ensures smooth production flow, reduces bottlenecks, and maximizes throughput, thereby enhancing overall operational productivity.

Common Challenges and Solutions in Managing Takt and Dwell Time

Common challenges in managing Takt time and Dwell time include balancing production speed with quality and minimizing idle periods while ensuring timely task completion. Solutions involve implementing real-time monitoring systems to track workflow, standardizing processes to reduce variability, and using lean methodologies such as value stream mapping to identify bottlenecks and optimize cycle times. Enhanced training and cross-functional collaboration further improve synchronization between takt and dwell times, promoting efficient resource utilization and meeting customer demand consistently.

Takt time Infographic

libterm.com

libterm.com