High-pressure processing (HPP) preserves food by applying intense pressure to eliminate harmful bacteria while maintaining freshness, flavor, and nutritional value. This cutting-edge technology extends shelf life without the need for preservatives or heat treatments, making it a preferred choice for clean-label products. Discover how HPP can enhance your food safety and quality in the rest of this article.

Table of Comparison

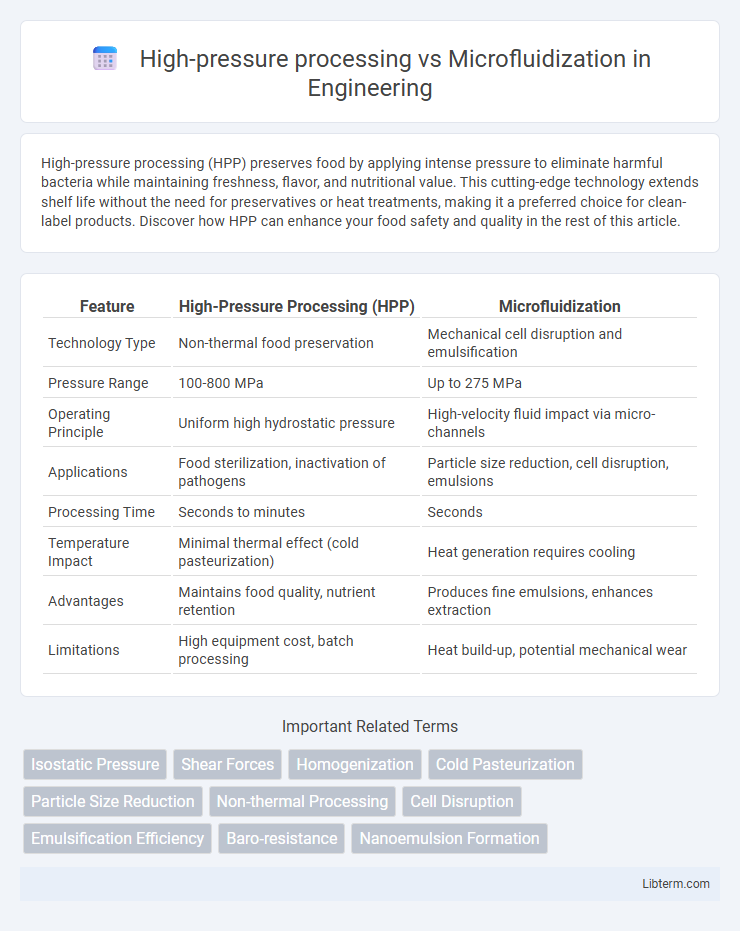

| Feature | High-Pressure Processing (HPP) | Microfluidization |

|---|---|---|

| Technology Type | Non-thermal food preservation | Mechanical cell disruption and emulsification |

| Pressure Range | 100-800 MPa | Up to 275 MPa |

| Operating Principle | Uniform high hydrostatic pressure | High-velocity fluid impact via micro-channels |

| Applications | Food sterilization, inactivation of pathogens | Particle size reduction, cell disruption, emulsions |

| Processing Time | Seconds to minutes | Seconds |

| Temperature Impact | Minimal thermal effect (cold pasteurization) | Heat generation requires cooling |

| Advantages | Maintains food quality, nutrient retention | Produces fine emulsions, enhances extraction |

| Limitations | High equipment cost, batch processing | Heat build-up, potential mechanical wear |

Introduction to Food Preservation Technologies

High-pressure processing (HPP) and microfluidization are advanced food preservation technologies that enhance safety and extend shelf life by targeting microbial inactivation without compromising nutritional quality. HPP employs extreme hydrostatic pressure, up to 600 MPa, to disrupt cellular structures of pathogens and spoilage organisms, while microfluidization uses high-pressure fluid forces to create fine emulsions and reduce particle size, improving texture and stability. Both methods offer non-thermal alternatives to traditional heat treatments, preserving sensory attributes and bioactive compounds in fresh and processed foods.

Overview of High-Pressure Processing (HPP)

High-Pressure Processing (HPP) is a non-thermal food preservation technique that uses pressures up to 600 MPa to inactivate microorganisms and enzymes while preserving sensory and nutritional qualities. This method ensures extended shelf life and safety without significant heat-induced nutrient loss or flavor alteration. HPP is widely applied in juice, seafood, and ready-to-eat meals industries due to its efficacy in maintaining product freshness and quality.

Principles of Microfluidization

Microfluidization operates by forcing fluids through microchannels at extremely high pressures, producing uniform particle size reduction and enhanced mixing through shear, impact, and cavitation forces. High-pressure processing (HPP) relies on applying static pressure to inactivate microorganisms and enzymes without significant heat generation. Microfluidization offers precise control over particle dispersion, making it ideal for emulsions and nanoscale formulations, while HPP is primarily used for pasteurization and sterilization of food products.

Mechanisms of Microbial Inactivation

High-pressure processing (HPP) inactivates microbes primarily through the disruption of cellular membranes and denaturation of key enzymes by applying pressures up to 600 MPa, causing irreversible cellular damage. Microfluidization uses intense shear forces, impact, and cavitation by forcing fluids through microchannels at high velocity, leading to physical breakage of microbial cell walls and membranes. Both methods preserve food quality while targeting microbial structures, but microfluidization tends to cause more mechanical cell disruption compared to the pressure-induced biochemical changes in HPP.

Impact on Nutritional Quality

High-pressure processing preserves vitamins, antioxidants, and enzymes by avoiding heat-induced degradation, maintaining high nutritional quality in food products. Microfluidization enhances nutrient bioavailability through cell disruption but may cause slight losses in heat-sensitive compounds due to shear and friction-generated heat. Both technologies offer non-thermal options for food preservation, with HPP excelling in nutrient retention and microfluidization improving nutrient accessibility.

Effects on Food Texture and Sensory Properties

High-pressure processing (HPP) preserves the natural texture of foods by inactivating microorganisms without significant heat, maintaining firmness and mouthfeel, while microfluidization induces mechanical shear that can alter particle size and improve homogeneity, resulting in smoother textures. HPP is effective in retaining sensory qualities such as color, flavor, and freshness due to minimal thermal impact, whereas microfluidization enhances creaminess and flavor release by modifying the structure of food emulsions and suspensions. Both methods improve food safety and shelf life but differ in their impact on texture and sensory properties, making selection dependent on specific product goals.

Comparative Processing Efficiency

High-pressure processing (HPP) uses pressures up to 600 MPa to inactivate microorganisms and enzymes efficiently in packaged foods, preserving nutritional and sensory qualities with minimal heat damage. Microfluidization forces fluids through microchannels at pressures around 138 MPa to create nanoemulsions, enhancing product stability and bioavailability through intense shear and impact forces. While HPP offers superior microbial inactivation for packaged products, microfluidization excels in texture modification and particle size reduction, making the choice dependent on specific processing goals and product types.

Industrial Applications and Scalability

High-pressure processing (HPP) enables preservation of food products by inactivating microbes while maintaining nutritional quality, widely adopted in juice, meat, and dairy industries for large-scale sterilization. Microfluidization offers precise particle size reduction and emulsion formation, enhancing texture and stability in pharmaceuticals, cosmetics, and beverage sectors, with scalable equipment supporting continuous high-throughput production. Industrial scalability of HPP is facilitated by batch or semi-continuous systems handling large volumes, whereas microfluidizers enable scalable continuous processing but require optimization for specific formulation viscosities.

Cost Analysis and Operational Considerations

High-pressure processing (HPP) generally incurs higher initial capital costs due to the need for robust pressure vessels and specialized equipment, whereas microfluidization systems often offer lower upfront expenses but require continuous maintenance of micro-channels. Operational costs for HPP include significant energy consumption for pressurization cycles, with slower batch processing times impacting throughput, while microfluidization operates continuously with lower energy per unit volume but demands frequent replacement of high-precision parts. Cost analysis should consider downtime, scalability, and product type, as HPP is favored for sterility and shelf-life extension despite higher costs, and microfluidization excels in particle size reduction and emulsification with operational efficiencies.

Future Trends in Non-Thermal Food Processing

High-pressure processing (HPP) and microfluidization are advancing non-thermal food preservation by enhancing microbial inactivation while preserving nutritional and sensory qualities. Future trends emphasize integrating these technologies with smart sensors and machine learning to optimize process parameters and improve energy efficiency. Research is also exploring combined methods, such as HPP with microfluidization, to achieve synergistic effects for safer, longer shelf-life foods without compromising freshness.

High-pressure processing Infographic

libterm.com

libterm.com