Axial load refers to a force applied along the longitudinal axis of a structural element, causing tension or compression within the material. Understanding how axial loads affect beams, columns, and other components is crucial for ensuring structural stability and safety. Explore the article to learn how axial load impacts your designs and the best practices for managing these forces.

Table of Comparison

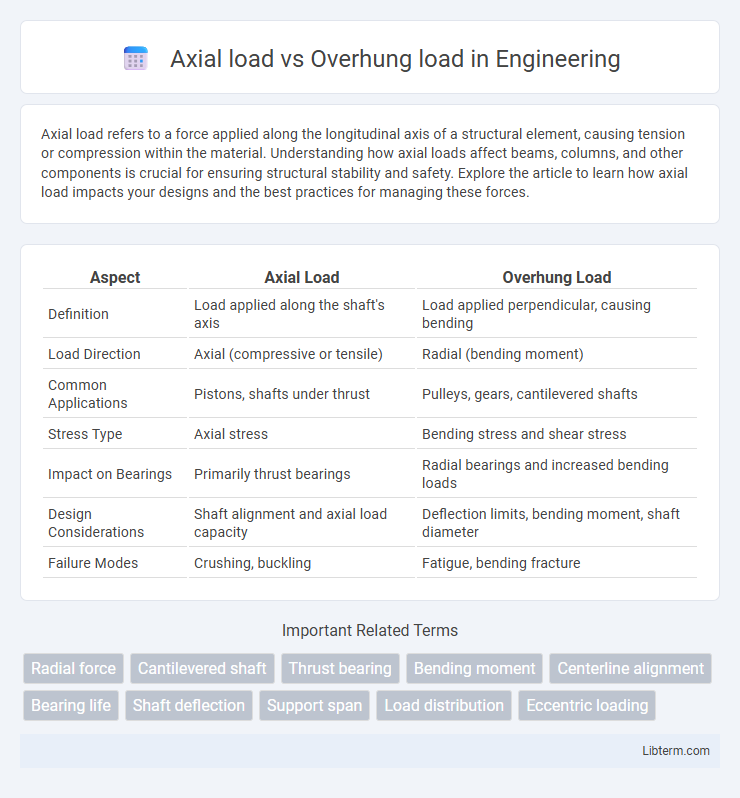

| Aspect | Axial Load | Overhung Load |

|---|---|---|

| Definition | Load applied along the shaft's axis | Load applied perpendicular, causing bending |

| Load Direction | Axial (compressive or tensile) | Radial (bending moment) |

| Common Applications | Pistons, shafts under thrust | Pulleys, gears, cantilevered shafts |

| Stress Type | Axial stress | Bending stress and shear stress |

| Impact on Bearings | Primarily thrust bearings | Radial bearings and increased bending loads |

| Design Considerations | Shaft alignment and axial load capacity | Deflection limits, bending moment, shaft diameter |

| Failure Modes | Crushing, buckling | Fatigue, bending fracture |

Introduction to Axial Load and Overhung Load

Axial load refers to the force applied along the longitudinal axis of a structural element, causing compression or tension within the member. Overhung load occurs when a load is applied at a distance from a support or bearing, creating bending moments and shear forces in rotating machinery components like shafts. Understanding the differences between axial load and overhung load is critical for designing mechanical systems, ensuring structural integrity, and preventing premature failure.

Definitions: What Are Axial and Overhung Loads?

Axial load refers to a force applied along the longitudinal axis of a shaft, causing compression or tension directly in line with the shaft's center. Overhung load occurs when a force is applied perpendicular to the shaft axis at a distance from the bearing support, creating bending moments and additional stress. Understanding the distinction is crucial for mechanical design, as axial loads primarily induce tensile or compressive stress, while overhung loads result in bending and shear stresses affecting shaft and bearing life.

Key Differences Between Axial and Overhung Loads

Axial load acts parallel to the shaft's axis, causing tension or compression, while overhung load applies perpendicular force, creating bending moments on the shaft. Axial loads typically influence thrust bearings by affecting shaft alignment, whereas overhung loads impact radial bearings due to the bending stress they introduce. Understanding these distinctions is crucial for selecting appropriate bearing types and ensuring optimal mechanical performance and longevity.

Engineering Applications of Axial Loads

Axial loads apply force along the longitudinal axis of a structural member, resulting in either tension or compression, which is critical in designing columns, shafts, and trusses to ensure stability and prevent buckling. Overhung loads generate bending moments due to forces applied at a distance from the support, commonly seen in cantilever beams and overhanging shafts, requiring careful consideration of shear stress and deflection. Engineering applications prioritize axial load analysis in load-bearing elements such as bridge piers, crane hooks, and elevator cables, where direct compressive or tensile forces dominate structural performance.

Engineering Applications of Overhung Loads

Overhung loads introduce bending moments and shear forces on shafts, requiring careful material selection and bearing placement to prevent premature failure in engineering applications such as conveyor systems, printing presses, and crane hooks. These loads demand robust shaft designs to withstand eccentric forces and minimize deflection, ensuring efficient power transmission and extended equipment lifespan. Proper analysis of overhung loads prevents misalignment and reduces wear, optimizing performance in mechanical assemblies subjected to lateral forces.

Effects on Shaft Design: Axial vs Overhung Load

Axial loads primarily induce compressive or tensile stresses along the shaft's length, requiring careful consideration of shaft material strength and end support design to prevent buckling or elongation. Overhung loads create bending moments and shear forces at the shaft overhangs, necessitating increased shaft diameter and enhanced bearing support to resist deflection and fatigue. Proper shaft design balances these load effects by optimizing geometry and material properties to ensure durability and operational reliability under combined loading conditions.

Common Failure Modes Associated with Each Load Type

Axial load failure modes often include buckling, excessive compressive deformation, and fatigue cracks due to cyclic stresses along the shaft axis. Overhung load typically causes bending stress leading to shaft deflection, bearing failure, and gear misalignment resulting from uneven load distribution. Both load types require careful shaft design and material selection to prevent fatigue, wear, and premature failure in rotating machinery.

Calculating Axial Load vs Overhung Load

Calculating axial load involves determining the force applied along the centerline of a shaft, typically measured in pounds or newtons, by analyzing factors such as weight, thrust, and tension in the system. Overhung load calculation focuses on the radial force exerted at a distance from the bearing support, using parameters like load magnitude, distance from the bearing, and shaft deflection to assess bending moments and stresses. Both calculations require precise measurement of forces and distances to ensure accurate load distribution and optimal bearing performance in mechanical systems.

Best Practices for Managing Axial and Overhung Loads

Proper management of axial and overhung loads is crucial for maintaining bearing performance and extending equipment lifespan. Axial loads should be minimized by ensuring proper shaft alignment and using thrust bearings designed to handle specific axial forces, while overhung loads require careful balancing and support to reduce bending moments on the shaft. Implementing regular maintenance checks and using load monitoring systems help detect excessive loads early, preventing premature failures and optimizing machine reliability.

Summary: Choosing the Right Load Strategy

Axial load applies force along the shaft's centerline, ensuring even distribution and minimal bending stress, ideal for applications requiring precise alignment and high load capacity. Overhung load exerts force perpendicular to the shaft, causing bending moments that increase bearing stress and potential misalignment, suitable for cantilevered or extended shaft designs. Selecting the right load strategy depends on the mechanical system's design constraints, load direction, and desired lifespan, with axial loads favored for longevity and overhung loads for spatial flexibility.

Axial load Infographic

libterm.com

libterm.com