Injection molding offers a highly efficient manufacturing process for producing complex plastic parts with consistent quality and minimal waste. This technique involves injecting molten material into molds, enabling rapid mass production and precise component replication. Discover how injection molding can optimize your production line and improve product performance by reading the rest of the article.

Table of Comparison

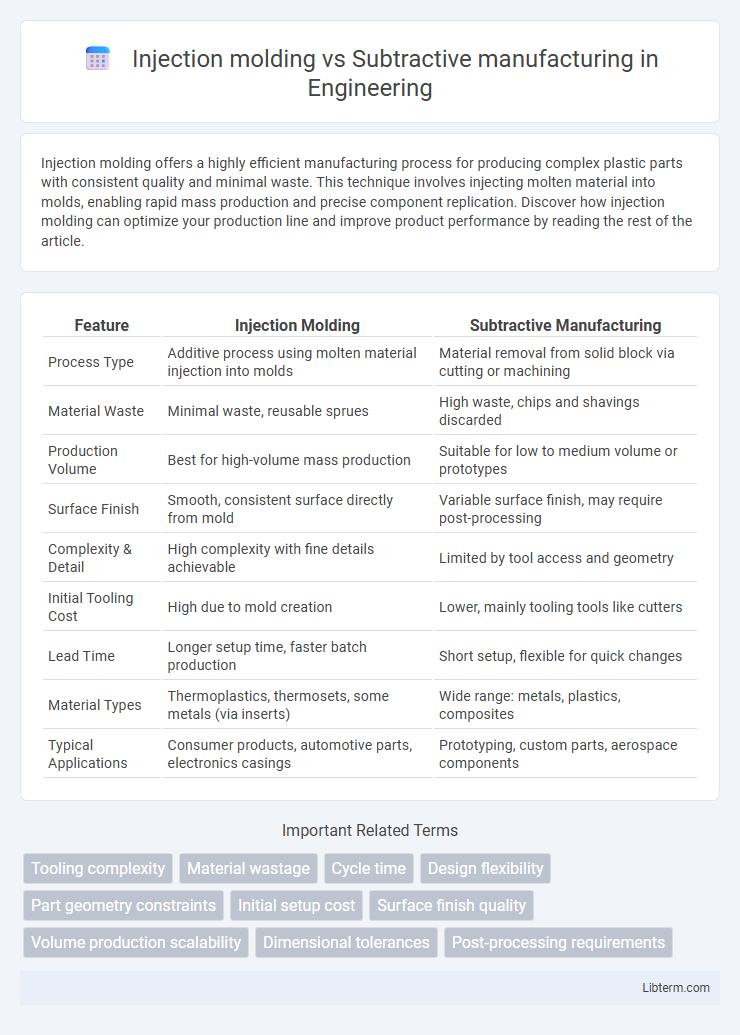

| Feature | Injection Molding | Subtractive Manufacturing |

|---|---|---|

| Process Type | Additive process using molten material injection into molds | Material removal from solid block via cutting or machining |

| Material Waste | Minimal waste, reusable sprues | High waste, chips and shavings discarded |

| Production Volume | Best for high-volume mass production | Suitable for low to medium volume or prototypes |

| Surface Finish | Smooth, consistent surface directly from mold | Variable surface finish, may require post-processing |

| Complexity & Detail | High complexity with fine details achievable | Limited by tool access and geometry |

| Initial Tooling Cost | High due to mold creation | Lower, mainly tooling tools like cutters |

| Lead Time | Longer setup time, faster batch production | Short setup, flexible for quick changes |

| Material Types | Thermoplastics, thermosets, some metals (via inserts) | Wide range: metals, plastics, composites |

| Typical Applications | Consumer products, automotive parts, electronics casings | Prototyping, custom parts, aerospace components |

Overview of Injection Molding and Subtractive Manufacturing

Injection molding is a manufacturing process that involves injecting molten material, typically plastic, into a mold cavity to create complex shapes with high precision and repeatability. Subtractive manufacturing, such as CNC machining, removes material from a solid block through cutting, drilling, or milling to achieve the desired geometry. Injection molding excels in mass production with low per-unit cost, while subtractive manufacturing offers flexibility for prototypes and low-volume production with intricate surface finishes.

Key Process Differences

Injection molding involves injecting molten material into a mold to form complex, high-volume parts with excellent surface finish and minimal waste. Subtractive manufacturing removes material from a solid block using cutting tools, enabling high precision but often generating more waste and longer cycle times. Injection molding excels in mass production efficiency, whereas subtractive manufacturing offers superior flexibility for prototyping and low-volume runs.

Material Compatibility and Selection

Injection molding supports a wide range of thermoplastics, including ABS, polypropylene, and polycarbonate, providing excellent material versatility for high-volume production. Subtractive manufacturing can process metals, plastics, and composites but is limited by tooling wear and material machinability, affecting material selection for precision parts. Material compatibility in injection molding favors polymers with good flow characteristics, while subtractive manufacturing demands materials with consistent machinability and minimal deformation during cutting.

Production Speed and Efficiency

Injection molding delivers high production speed by enabling rapid replication of complex parts through molten material injection into molds, ideal for large-volume manufacturing. Subtractive manufacturing, such as CNC machining, involves material removal from solid blocks, resulting in slower production cycles and limited batch efficiency. Efficiency in injection molding typically surpasses subtractive methods due to lower per-unit costs and reduced waste in mass production scenarios.

Cost Comparison and Budget Considerations

Injection molding offers lower per-unit costs for high-volume production due to efficient material use and automated processes, despite substantial initial tooling expenses ranging from $10,000 to $100,000. Subtractive manufacturing presents higher cost per part in large quantities because of slower machining speeds and significant material waste, but benefits from lower upfront investment, typically under $10,000 for standard CNC setups. Budget considerations favor injection molding for mass production exceeding thousands of units, while subtractive methods suit prototyping or low-volume runs where flexibility and reduced initial costs are critical.

Part Design Flexibility and Complexity

Injection molding offers high design flexibility for complex parts with intricate details, undercuts, and varying wall thicknesses, enabling mass production of consistent, precise components. Subtractive manufacturing excels in producing parts with complex geometries, sharp edges, and tight tolerances directly from a solid block, accommodating one-off or low-volume production with rapid design changes. Part design complexity in injection molding is often limited by mold tooling constraints, while subtractive processes are constrained by tool access and machining paths.

Surface Finish and Tolerances

Injection molding provides superior surface finish and tighter tolerances compared to subtractive manufacturing, enabling complex geometries with smooth, consistent surfaces directly from the mold. Subtractive manufacturing often requires additional post-processing to achieve comparable surface quality and precision, as machining marks and tool deflection can affect the final part. Injection molding tolerances typically range from +-0.05 mm to +-0.1 mm, whereas subtractive methods vary widely but generally offer looser tolerances depending on the tooling and machine precision.

Scalability for Mass Production

Injection molding offers superior scalability for mass production due to its ability to produce large volumes of identical parts rapidly with minimal waste, making it ideal for high-demand industries such as automotive and consumer electronics. Subtractive manufacturing, while precise, is limited by longer cycle times and higher material costs, reducing its efficiency in large-scale production runs. The upfront investment in injection molding molds is offset by lower per-unit costs as production volume increases, enabling cost-effective scalability.

Environmental Impact and Sustainability

Injection molding significantly reduces material waste compared to subtractive manufacturing, as it uses precise amounts of molten material molded into shape, minimizing scrap. Subtractive manufacturing often results in higher energy consumption and generates substantial material offcuts, increasing landfill burden and recycling challenges. The sustainability advantage of injection molding is evident in its efficiency and ability to incorporate recycled plastics, supporting circular economy initiatives.

Industry Applications and Use Cases

Injection molding is widely used in mass production across automotive, consumer electronics, and medical device industries due to its efficiency in creating complex plastic parts with high precision. Subtractive manufacturing, including CNC machining, excels in aerospace, prototyping, and custom metal components where tight tolerances and material integrity are critical. Both methods serve distinct roles: injection molding supports scalability for polymer products, while subtractive manufacturing delivers flexibility and accuracy for metals and intricate designs.

Injection molding Infographic

libterm.com

libterm.com