PID control is a powerful method used in industrial automation to maintain desired system performance by continuously adjusting process variables through proportional, integral, and derivative actions. This approach helps optimize stability, reduce overshoot, and minimize steady-state error, ensuring precise regulation of temperature, speed, or pressure in various applications. Discover how implementing effective PID control can enhance your system's efficiency and reliability by reading the rest of the article.

Table of Comparison

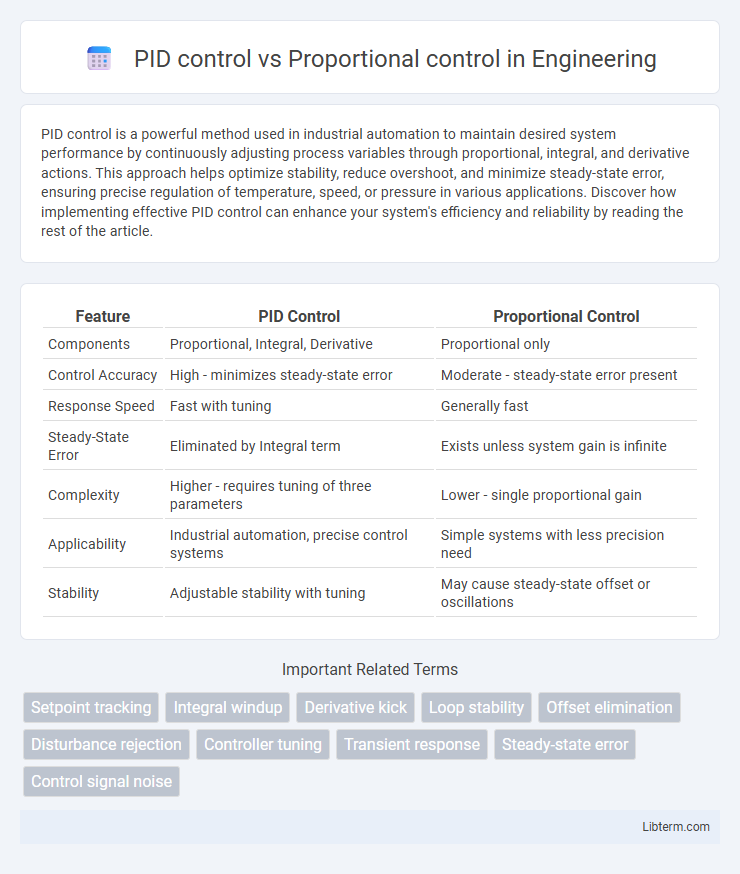

| Feature | PID Control | Proportional Control |

|---|---|---|

| Components | Proportional, Integral, Derivative | Proportional only |

| Control Accuracy | High - minimizes steady-state error | Moderate - steady-state error present |

| Response Speed | Fast with tuning | Generally fast |

| Steady-State Error | Eliminated by Integral term | Exists unless system gain is infinite |

| Complexity | Higher - requires tuning of three parameters | Lower - single proportional gain |

| Applicability | Industrial automation, precise control systems | Simple systems with less precision need |

| Stability | Adjustable stability with tuning | May cause steady-state offset or oscillations |

Introduction to Control Systems

PID control enhances Proportional control by integrating Integral and Derivative terms, which improves system stability and minimizes steady-state error. Proportional control adjusts output proportionally to the current error but may cause persistent offset in the system response. Control systems utilizing PID controllers achieve faster settling times and better disturbance rejection compared to those using only Proportional control.

Understanding Proportional Control

Proportional control adjusts output proportionally to the error signal, providing a straightforward method to reduce steady-state error but often resulting in an offset due to the lack of integral action. Unlike PID control, which combines proportional, integral, and derivative terms to enhance stability, speed, and accuracy, proportional control alone cannot eliminate persistent deviations from the setpoint. Understanding proportional control is essential for grasping basic feedback mechanisms before advancing to the more complex PID control strategies used in industrial automation and process control.

What is PID Control?

PID control is a feedback mechanism widely used in industrial automation to maintain desired system performance by continuously adjusting process variables. It combines proportional, integral, and derivative actions to correct errors between a measured process variable and a desired setpoint, improving stability and response time. Unlike proportional control, which only reacts to current error, PID control addresses past accumulated errors and predicts future trends for more precise and robust system regulation.

Key Differences Between PID and Proportional Control

PID control integrates proportional, integral, and derivative actions to minimize error, whereas proportional control relies solely on proportional response to error. The integral component in PID eliminates steady-state error by accumulating past errors, while derivative action predicts future errors, enhancing system stability and responsiveness. Proportional control often leads to steady-state errors due to lack of integral correction, making PID more effective for complex or precise control applications.

Advantages of Proportional Control

Proportional control offers simplicity and faster response times compared to PID control, making it ideal for systems where quick adjustments are necessary without complex tuning. It requires fewer parameters to set, reducing the risk of instability and making it easier to implement in industrial automation and process control applications. This control method efficiently handles processes with minimal lag and steady-state error under consistent conditions, optimizing operational reliability.

Benefits of PID Control

PID control offers superior precision by continuously adjusting the control output based on proportional, integral, and derivative terms, minimizing steady-state error and improving system stability. It effectively eliminates offset errors present in proportional control alone, ensuring more accurate and consistent performance. This enhanced responsiveness and robustness make PID controllers ideal for complex, dynamic systems requiring precise regulation under varying conditions.

Common Applications of Proportional Controllers

Proportional controllers are widely used in temperature control systems, flow control, and pressure regulation due to their simplicity and effectiveness in maintaining steady-state error within acceptable limits. Unlike PID controllers, which combine proportional, integral, and derivative actions for more complex dynamic response, proportional controllers provide immediate correction proportional to the error signal, making them ideal for applications with relatively stable process dynamics. Common industries employing proportional control include HVAC systems, water treatment plants, and manufacturing processes where precise but straightforward control is sufficient.

Real-World Uses of PID Controllers

PID controllers are widely used in industrial automation, robotics, and process control because they provide precise control by continuously adjusting the proportional, integral, and derivative terms to minimize error. Unlike simple proportional control, which only reacts to present error, PID control accounts for past errors and predicts future trends, leading to more stable and accurate system performance. Real-world applications include temperature regulation in HVAC systems, speed control in motors, and chemical process stabilization, where maintaining consistent output despite changing conditions is critical.

Performance Comparison: PID vs Proportional Control

PID control offers superior performance compared to proportional control by minimizing steady-state error and improving system stability through integral and derivative actions. Proportional control alone often results in a steady-state offset and slower response, especially in systems with load variations or disturbances. The addition of integral control in PID eliminates steady-state error, while derivative control enhances transient response, resulting in more precise and robust process control.

Choosing the Right Controller for Your System

Selecting the right controller depends on system complexity and desired performance; PID control offers precise regulation by addressing proportional, integral, and derivative actions, making it ideal for systems requiring minimal steady-state error and quick response. Proportional control, while simpler and easier to implement, is best suited for processes where minor steady-state errors are acceptable, and system dynamics are less demanding. Evaluating system stability, response time, and tolerance to disturbances ensures optimal controller choice tailored to operational needs.

PID control Infographic

libterm.com

libterm.com