Calibration ensures the accuracy and reliability of measurement instruments by comparing them against known standards, reducing errors and improving performance. Proper calibration maintains quality control, enhances safety, and extends the lifespan of your equipment. Explore the full article to learn how precise calibration can benefit your operations.

Table of Comparison

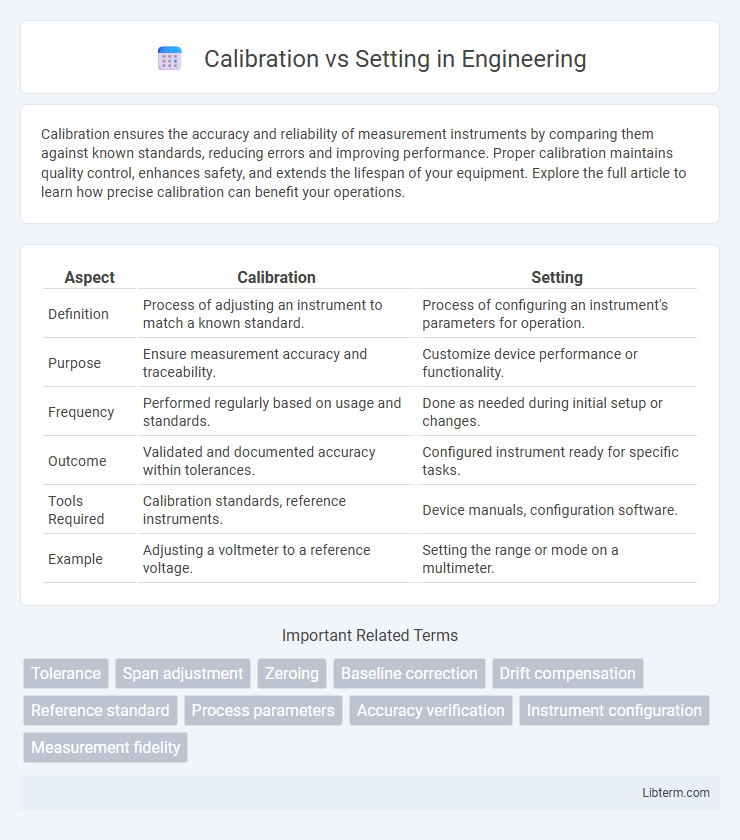

| Aspect | Calibration | Setting |

|---|---|---|

| Definition | Process of adjusting an instrument to match a known standard. | Process of configuring an instrument's parameters for operation. |

| Purpose | Ensure measurement accuracy and traceability. | Customize device performance or functionality. |

| Frequency | Performed regularly based on usage and standards. | Done as needed during initial setup or changes. |

| Outcome | Validated and documented accuracy within tolerances. | Configured instrument ready for specific tasks. |

| Tools Required | Calibration standards, reference instruments. | Device manuals, configuration software. |

| Example | Adjusting a voltmeter to a reference voltage. | Setting the range or mode on a multimeter. |

Understanding Calibration and Setting

Calibration ensures measurement instruments deliver precise and accurate results by comparing and adjusting them against established standards. Setting involves configuring devices to specific parameters or operational conditions without verifying measurement accuracy. Understanding calibration emphasizes accuracy validation, while setting focuses on device adjustment for desired functionality.

Key Differences Between Calibration and Setting

Calibration involves comparing and adjusting an instrument's measurements to a known standard to ensure accuracy, while setting refers to configuring the instrument's parameters or controls for proper operation. Calibration is a precise process aimed at eliminating measurement errors, often requiring traceable standards and documented procedures. Setting focuses on initializing or modifying device settings without necessarily verifying measurement accuracy.

Importance of Calibration in Precision

Calibration ensures measurement accuracy by comparing instruments against known standards, critical for maintaining precision in scientific and industrial applications. Setting adjusts equipment parameters within predefined limits, but without calibration, settings risk drifting and causing errors. Accurate calibration minimizes uncertainty, enhances product quality, and ensures compliance with regulatory standards.

Role of Setting in Equipment Operation

Setting in equipment operation defines the precise parameters and configurations required for optimal device functionality, ensuring accurate performance according to manufacturer specifications. Unlike calibration, which adjusts measurement accuracy against a standard, setting establishes the initial operational framework that guides proper equipment behavior during use. Proper setting minimizes errors, enhances reliability, and lays the foundation for consistent equipment output in various industrial and technical applications.

Calibration Methods and Standards

Calibration involves comparing an instrument's measurements against recognized standards such as ISO/IEC 17025 or NIST-traceable references to ensure accuracy and traceability. Common calibration methods include fixed-point calibration, comparison calibration, and substitution calibration, each chosen based on equipment type and required precision. Setting, in contrast, refers to adjusting the device to meet specific performance criteria after calibration verifies any deviation.

Step-by-Step Guide to Setting Adjustments

Setting adjustments involve a systematic step-by-step guide to modify device parameters, ensuring optimal performance without altering the accuracy baseline. Begin by identifying the specific settings requiring modification, then use manufacturer-provided instructions or software tools to carefully adjust parameters like sensitivity, threshold, or output levels. Confirm changes by conducting tests and recordings to verify improvements, maintaining a log for consistency and future reference.

Common Misconceptions: Calibration vs Setting

Calibration involves adjusting an instrument to align its measurements with a recognized standard, ensuring accuracy and reliability over time, while setting refers to configuring device parameters or operational limits without comparison to an external reference. A common misconception is that setting an instrument is equivalent to calibration, but calibration requires traceable standards and documented procedures to verify measurement correctness. Confusing these terms can lead to improper quality control and measurement errors in critical processes.

Impact on Performance and Accuracy

Calibration aligns measurement instruments with known standards to ensure accurate and consistent data, directly enhancing performance by reducing errors and improving reliability. Setting adjusts device parameters to desired operational values but may not guarantee precision without prior calibration. Proper calibration is essential for accuracy, while settings optimize functionality based on calibrated benchmarks.

Industry Examples: Calibration vs Setting

Calibration ensures industrial instruments like pressure gauges and thermometers maintain accuracy by comparing measurements against known standards, critical in manufacturing sectors such as pharmaceuticals and aerospace. Setting involves adjusting equipment parameters to achieve desired performance, common in automotive assembly lines where robotic arms are programmed to precise positions. Both processes are essential for quality control, with calibration verifying measurement accuracy and setting optimizing operational conditions.

Best Practices for Maintaining Calibration and Setting

Maintaining calibration and setting best practices involves regularly verifying equipment accuracy against industry standards and adjusting devices to ensure precision in measurements. Calibration requires the use of certified reference materials and adherence to the manufacturer's guidelines, while setting emphasizes configuring instruments to optimal parameters for specific tasks. Implementing routine checks, documenting results, and training personnel in calibration techniques significantly enhance consistency and reliability in operational environments.

Calibration Infographic

libterm.com

libterm.com