Axial-flow compressors are essential components in jet engines, using a series of rotating blades to continuously compress air along the axis of the engine, resulting in high efficiency and pressure ratios. These compressors provide improved performance and fuel efficiency for turbines, helicopters, and industrial gas turbines, making them critical in modern aerospace and energy applications. Discover how understanding axial-flow technology can enhance your knowledge of engine design and operation by reading the full article.

Table of Comparison

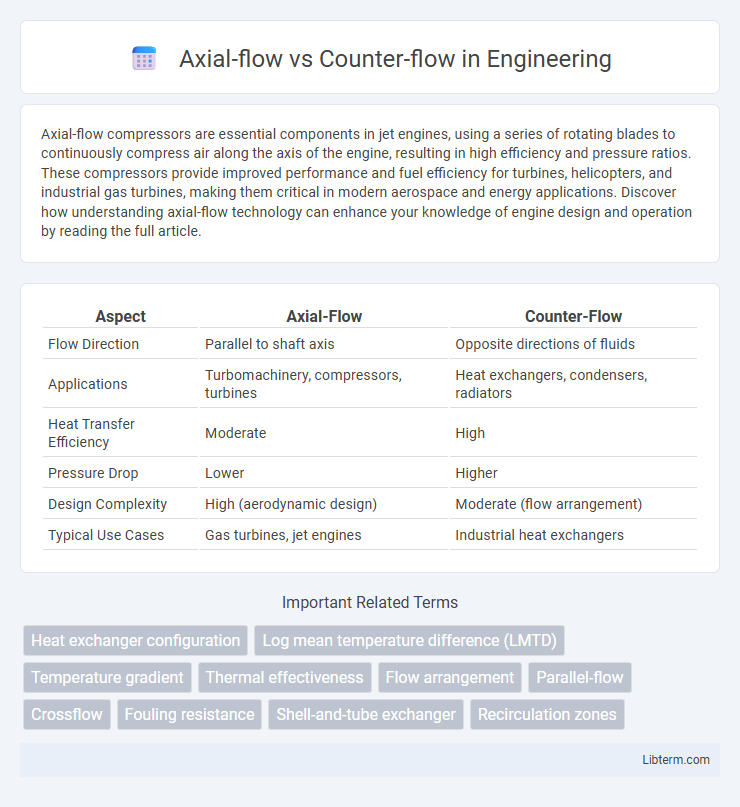

| Aspect | Axial-Flow | Counter-Flow |

|---|---|---|

| Flow Direction | Parallel to shaft axis | Opposite directions of fluids |

| Applications | Turbomachinery, compressors, turbines | Heat exchangers, condensers, radiators |

| Heat Transfer Efficiency | Moderate | High |

| Pressure Drop | Lower | Higher |

| Design Complexity | High (aerodynamic design) | Moderate (flow arrangement) |

| Typical Use Cases | Gas turbines, jet engines | Industrial heat exchangers |

Introduction to Heat Exchanger Flow Configurations

Axial-flow and counter-flow are fundamental heat exchanger flow configurations that significantly impact thermal efficiency and fluid dynamics. In axial-flow heat exchangers, the fluid flows parallel to the axis, promoting straightforward and uniform heat transfer, whereas counter-flow configurations have fluids moving in opposite directions, maximizing temperature gradients and enhancing heat exchange effectiveness. Selecting the appropriate flow configuration depends on factors like desired heat transfer rate, pressure drop, and system design requirements.

Understanding Axial-flow and Counter-flow Designs

Axial-flow and counter-flow designs optimize heat exchange processes by directing fluid streams in distinct ways to maximize thermal transfer efficiency. Axial-flow designs align fluid streams parallel within the heat exchanger, minimizing pressure drop and allowing for higher flow rates suitable for applications requiring compact, lightweight equipment. Counter-flow configurations arrange fluids to move in opposite directions, increasing temperature gradient and heat transfer, which is ideal for maximizing thermal recovery in industrial boilers and refrigeration systems.

Key Differences Between Axial-flow and Counter-flow

Axial-flow machines move fluid parallel to the axis of rotation, enabling high flow rates with moderate pressure increases, while counter-flow systems direct fluid flow in opposite paths to maximize heat transfer efficiency. Axial-flow configurations are commonly used in turbines and compressors due to their compact design and continuous flow, whereas counter-flow arrangements excel in heat exchangers by maintaining a higher temperature gradient between fluids. The key differences lie in flow direction, application focus, and efficiency optimization, with axial-flow favoring dynamic performance and counter-flow prioritizing thermal exchange effectiveness.

Heat Transfer Efficiency Comparison

Axial-flow heat exchangers typically exhibit lower heat transfer efficiency due to reduced fluid velocity and less effective turbulence compared to counter-flow designs, which maximize temperature gradients by promoting opposite fluid flow directions. Counter-flow heat exchangers achieve higher thermal performance, often resulting in 10-30% greater heat transfer efficiency, as the continuous temperature difference between hot and cold fluids enhances energy exchange. Industrial applications favor counter-flow configurations for improved heat recovery and reduced energy consumption in processes requiring compact and efficient heat transfer solutions.

Pressure Drop Analysis

Axial-flow heat exchangers typically exhibit lower pressure drop compared to counter-flow configurations due to the parallel alignment of fluid flow, which reduces flow resistance and turbulence. Counter-flow designs maximize heat transfer efficiency but incur higher pressure drops because fluids flow in opposite directions, increasing frictional losses and requiring more pump power. Precise pressure drop analysis involves evaluating parameters such as fluid velocity, viscosity, channel geometry, and heat exchanger surface roughness to optimize performance trade-offs.

Applications of Axial-flow Systems

Axial-flow systems excel in applications requiring high flow rates with relatively low pressure, such as ventilation, cooling towers, and aircraft jet engines. Their streamlined design enables efficient air movement along the axis, making them ideal for HVAC systems, turbochargers, and power generation turbines. Industries relying on continuous and large volumes of airflow benefit significantly from axial-flow technology due to its compact size and energy efficiency.

Applications of Counter-flow Systems

Counter-flow systems excel in applications requiring efficient heat exchange, such as HVAC units, refrigeration, and chemical processing plants. Their design allows for maximum temperature gradient maintenance between fluids, enhancing thermal transfer efficiency in power plants and air conditioning systems. Industries leverage counter-flow heat exchangers to optimize energy recovery and reduce operational costs effectively.

Advantages and Disadvantages of Each Flow Type

Axial-flow heat exchangers offer high efficiency in handling large fluid volumes with minimal pressure drop, making them ideal for applications requiring parallel fluid paths and continuous flow. Counter-flow heat exchangers provide superior heat transfer performance by maintaining a higher temperature gradient along the entire heat exchanger length, maximizing thermal efficiency. Axial-flow designs tend to be simpler and more compact but may suffer from lower temperature differences, while counter-flow setups are more complex and expensive but achieve better energy recovery and reduced fluid temperatures.

Selecting the Right Configuration for Your Needs

Choosing between axial-flow and counter-flow heat exchangers depends on factors like space constraints, efficiency needs, and fluid characteristics. Axial-flow configurations excel in high flow rate applications with lower pressure drops, while counter-flow designs provide superior thermal performance with closer temperature approaches. Assessing flow rates, temperature differences, and installation space ensures optimal selection tailored to specific operational requirements.

Future Trends in Heat Exchanger Flow Design

Axial-flow heat exchangers promote efficient fluid movement along the length of the device, enhancing thermal transfer in compact spaces, while counter-flow designs maximize temperature gradients by directing fluids in opposite directions, achieving superior heat exchange effectiveness. Future trends emphasize integrating advanced materials like graphene and employing AI-driven flow optimization algorithms to improve energy efficiency and reduce fouling in both axial-flow and counter-flow heat exchangers. Innovations in additive manufacturing also enable complex flow geometries, increasing surface area and turbulence control for next-generation heat exchanger designs.

Axial-flow Infographic

libterm.com

libterm.com