Hydraulic drive systems convert fluid power into mechanical motion, providing precise control and high torque in various industrial applications. These systems enhance efficiency and reliability by utilizing pressurized fluid to transmit energy. Explore the article to understand how your operations can benefit from advanced hydraulic drive technology.

Table of Comparison

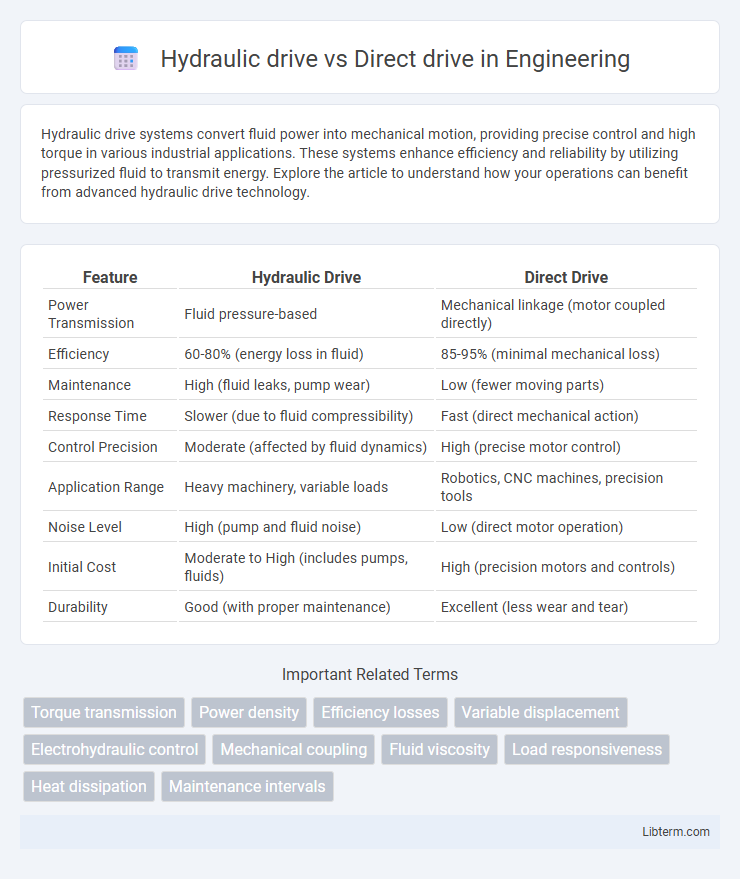

| Feature | Hydraulic Drive | Direct Drive |

|---|---|---|

| Power Transmission | Fluid pressure-based | Mechanical linkage (motor coupled directly) |

| Efficiency | 60-80% (energy loss in fluid) | 85-95% (minimal mechanical loss) |

| Maintenance | High (fluid leaks, pump wear) | Low (fewer moving parts) |

| Response Time | Slower (due to fluid compressibility) | Fast (direct mechanical action) |

| Control Precision | Moderate (affected by fluid dynamics) | High (precise motor control) |

| Application Range | Heavy machinery, variable loads | Robotics, CNC machines, precision tools |

| Noise Level | High (pump and fluid noise) | Low (direct motor operation) |

| Initial Cost | Moderate to High (includes pumps, fluids) | High (precision motors and controls) |

| Durability | Good (with proper maintenance) | Excellent (less wear and tear) |

Introduction to Hydraulic and Direct Drive Systems

Hydraulic drive systems transmit power through pressurized fluid to generate high torque and precise control, commonly used in heavy machinery and industrial applications. Direct drive systems eliminate intermediate components by connecting the motor directly to the load, offering higher efficiency, reduced maintenance, and improved responsiveness. Choosing between hydraulic and direct drive depends on factors like torque requirements, system complexity, and operational environment.

How Hydraulic Drive Systems Work

Hydraulic drive systems operate by using pressurized fluid to transmit power from the motor to the mechanical components, enabling precise control of torque and speed through fluid flow and pressure regulation. The system consists of a pump that pressurizes hydraulic fluid, valves that direct fluid flow, and actuators such as hydraulic cylinders or motors that convert fluid power into mechanical motion. These systems offer high force density and smooth operation, making them ideal for heavy-duty applications requiring controlled power delivery.

How Direct Drive Systems Operate

Direct drive systems operate by connecting the motor directly to the load, eliminating the need for intermediate components like gears or belts, which enhances efficiency and precision. These systems utilize high-torque, low-speed electric motors to provide immediate responsiveness and reduced mechanical complexity. The absence of transmission elements reduces maintenance requirements and energy losses, making direct drive ideal for applications demanding high accuracy and reliability.

Performance Comparison: Hydraulic vs Direct Drive

Hydraulic drives deliver high torque at low speeds with excellent shock load resistance and precise force control, making them ideal for heavy-duty industrial applications. Direct drives provide superior efficiency, faster response times, and reduced maintenance due to fewer mechanical components, enhancing performance in applications requiring high precision and repeatability. Comparing performance, hydraulic systems excel in power density and overload capacity, while direct drives outperform in dynamic accuracy and energy efficiency.

Efficiency Differences Between Hydraulic and Direct Drives

Hydraulic drives typically exhibit lower energy efficiency compared to direct drives due to energy losses in fluid friction, pump leakage, and heat dissipation, often achieving around 70-85% efficiency. Direct drives, leveraging direct mechanical coupling with fewer moving parts, can reach efficiencies above 90%, minimizing power loss and improving energy utilization. The higher efficiency of direct drives translates into reduced operational costs and enhanced performance, especially in applications requiring precise speed control and torque delivery.

Maintenance Requirements and Longevity

Hydraulic drives require regular maintenance, including fluid checks, filter replacements, and seal inspections to prevent leaks and ensure optimal performance, which can increase downtime. Direct drives have fewer moving parts and no hydraulic fluid, resulting in lower maintenance needs and longer service life due to reduced wear and tear. Longevity in direct drives is often superior, especially in environments where contamination or hydraulic system failures are common, making them more reliable for long-term use.

Cost Considerations: Initial and Long-Term

Hydraulic drives generally have lower initial costs compared to direct drives due to simpler components and widespread availability. However, long-term expenses for hydraulic systems can increase because of maintenance requirements like fluid replacement, seal repairs, and potential leakage issues. Direct drives often demand higher upfront investment but provide reduced operational and maintenance costs over time, offering better cost efficiency for applications with continuous or precision use.

Application Suitability for Each Drive Type

Hydraulic drives excel in heavy-duty industrial applications requiring high torque and variable speed control, such as construction machinery, agricultural equipment, and mining operations due to their robustness and ability to handle peak loads. Direct drives are best suited for precision applications like robotics, CNC machines, and electric vehicles where high efficiency, low maintenance, and accurate speed control are critical. The choice between hydraulic and direct drive depends on the specific demands of torque, speed control precision, maintenance intervals, and environmental considerations in the application.

Pros and Cons of Hydraulic Drives

Hydraulic drives offer high torque and precise control, making them ideal for heavy-duty applications such as construction and industrial machinery. Their ability to operate under extreme conditions and handle overloads without damage is a significant advantage, though they require regular maintenance and are prone to leaks, which can lead to efficiency losses. Compared to direct drives, hydraulic systems are generally bulkier, less energy-efficient, and generate more noise, limiting their use where compactness and quiet operation are critical.

Pros and Cons of Direct Drives

Direct drive systems offer high efficiency and precise control by eliminating intermediary components like gears or belts, resulting in reduced power loss and maintenance requirements. They provide smoother operation with less noise and vibration, enhancing machine reliability and longevity. However, direct drives typically have higher initial costs and may be limited in torque capacity compared to hydraulic drives, making them less suitable for extremely high-force applications.

Hydraulic drive Infographic

libterm.com

libterm.com