Manual control provides precise, hands-on operation for systems requiring real-time adjustments and direct user input. This approach enhances accuracy and responsiveness, ensuring tasks are completed according to specific preferences. Explore the rest of the article to understand how manual control can improve your system's performance.

Table of Comparison

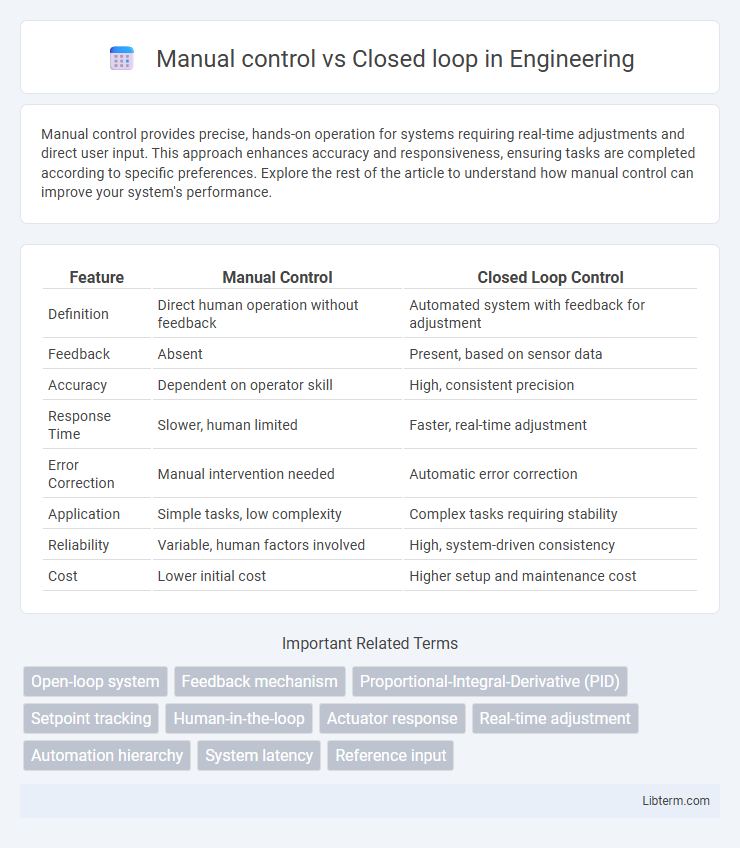

| Feature | Manual Control | Closed Loop Control |

|---|---|---|

| Definition | Direct human operation without feedback | Automated system with feedback for adjustment |

| Feedback | Absent | Present, based on sensor data |

| Accuracy | Dependent on operator skill | High, consistent precision |

| Response Time | Slower, human limited | Faster, real-time adjustment |

| Error Correction | Manual intervention needed | Automatic error correction |

| Application | Simple tasks, low complexity | Complex tasks requiring stability |

| Reliability | Variable, human factors involved | High, system-driven consistency |

| Cost | Lower initial cost | Higher setup and maintenance cost |

Introduction to Manual Control vs Closed Loop

Manual control relies on human intervention to adjust system variables directly, often suited for simple or low-speed processes. Closed loop control integrates feedback mechanisms enabling automatic real-time adjustments based on sensor data, enhancing precision and stability. Understanding the distinctions between manual control and closed loop systems is essential for selecting the appropriate control strategy in industrial automation and process control applications.

Defining Manual Control Systems

Manual control systems rely on human input to regulate processes or machinery, lacking automatic feedback mechanisms. Operators continuously monitor system performance and make adjustments based on real-time observations without sensor-driven corrections. These systems contrast with closed-loop controls, where sensors measure output and controllers automatically adjust inputs to maintain desired conditions.

Understanding Closed Loop Control Systems

Closed loop control systems use feedback to automatically adjust system output, enhancing precision and stability in applications like temperature regulation and robotics. Unlike manual control, where human intervention is required for adjustments, closed loop systems continuously monitor performance and correct errors in real-time. This dynamic self-correction mechanism improves efficiency and reduces the risk of system deviations or failures.

Key Differences Between Manual and Closed Loop

Manual control requires human intervention to adjust system inputs based on observation, relying heavily on operator skill and judgment. Closed loop control uses feedback from system outputs to automatically adjust inputs, ensuring precise regulation and improved stability. Key differences include the presence of feedback mechanisms, automation level, and accuracy in responding to disturbances.

Advantages of Manual Control

Manual control offers precise human judgment and adaptability in dynamic environments, allowing operators to respond quickly to unexpected changes. It enables intuitive handling of complex machinery without reliance on sensors or automated feedback systems. This control method is often preferred in situations requiring immediate intervention and customized adjustments without the delays associated with closed-loop processing.

Advantages of Closed Loop Systems

Closed loop systems offer enhanced precision by continuously monitoring output and adjusting inputs to maintain desired performance, reducing errors caused by external disturbances. These systems improve stability and responsiveness, enabling automatic correction without human intervention, which increases overall efficiency and reliability. Their ability to self-regulate makes them ideal for complex applications requiring consistent accuracy and real-time adaptability.

Typical Applications for Manual Control

Typical applications for manual control include simple machine operations such as valve adjustments in water treatment plants and manual speed regulation in conveyor belts. Operators directly manipulate controls in manufacturing assembly lines where precise automation is unnecessary or too costly. Manual control is favored in scenarios requiring human judgment, such as pilot control in small aircraft or manual override during emergencies in industrial systems.

Typical Applications for Closed Loop Control

Closed loop control systems are widely used in applications requiring precise regulation and continuous feedback, such as temperature control in HVAC systems, speed control in electric motors, and automated manufacturing processes. These systems rely on sensors to monitor output variables and adjust inputs dynamically, ensuring accuracy and stability in operations. Typical closed loop applications include robotics, aerospace navigation, and chemical process control where maintaining desired performance despite disturbances is critical.

Challenges and Limitations of Each Approach

Manual control systems face challenges including human error, limited reaction speed, and fatigue, which reduce precision and reliability in dynamic environments. Closed-loop control systems, while offering automated feedback and improved accuracy, encounter limitations such as sensor inaccuracies, system latency, and increased complexity that can lead to instability or oscillations. Both approaches require careful consideration of application-specific demands to balance responsiveness, accuracy, and robustness effectively.

Choosing Between Manual and Closed Loop Control

Choosing between manual control and closed loop control depends on system complexity and precision requirements, where closed loop systems use feedback to continuously adjust and maintain desired output, increasing accuracy. Manual control offers simplicity and flexibility for straightforward tasks but lacks real-time correction, making it less suitable for dynamic or sensitive processes. Closed loop control systems are ideal for applications demanding high reliability and consistent performance, including robotics, automotive systems, and industrial automation.

Manual control Infographic

libterm.com

libterm.com