The elastic limit defines the maximum stress a material can withstand without undergoing permanent deformation. When stress exceeds this threshold, the material will not return to its original shape, leading to structural changes. Discover how understanding the elastic limit impacts material selection and design by reading the full article.

Table of Comparison

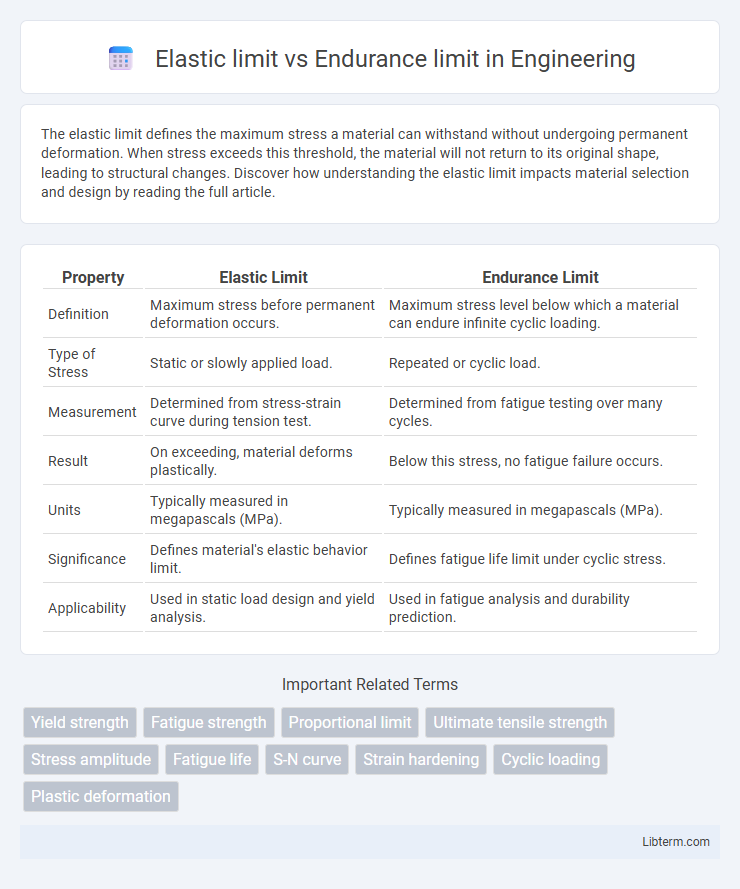

| Property | Elastic Limit | Endurance Limit |

|---|---|---|

| Definition | Maximum stress before permanent deformation occurs. | Maximum stress level below which a material can endure infinite cyclic loading. |

| Type of Stress | Static or slowly applied load. | Repeated or cyclic load. |

| Measurement | Determined from stress-strain curve during tension test. | Determined from fatigue testing over many cycles. |

| Result | On exceeding, material deforms plastically. | Below this stress, no fatigue failure occurs. |

| Units | Typically measured in megapascals (MPa). | Typically measured in megapascals (MPa). |

| Significance | Defines material's elastic behavior limit. | Defines fatigue life limit under cyclic stress. |

| Applicability | Used in static load design and yield analysis. | Used in fatigue analysis and durability prediction. |

Understanding the Elastic Limit

The elastic limit represents the maximum stress a material can withstand without permanent deformation, ensuring it returns to its original shape after the load is removed. This threshold is critical in design applications to prevent structural failure and maintain material integrity under operational loads. Unlike the endurance limit, which concerns cyclic stresses, the elastic limit defines the boundary for elastic behavior under a single, static load.

Defining the Endurance Limit

The endurance limit defines the maximum stress amplitude a material can withstand for an infinite number of load cycles without experiencing fatigue failure. Unlike the elastic limit, which marks the maximum stress before permanent deformation, the endurance limit specifically relates to fatigue strength under repeated or cyclic loading. Materials such as ferrous metals typically exhibit a distinct endurance limit, making it a critical parameter in designing components subjected to fluctuating stresses.

Key Differences Between Elastic and Endurance Limits

The elastic limit represents the maximum stress a material can endure without permanent deformation, whereas the endurance limit defines the maximum stress a material can withstand for an infinite number of load cycles without fatigue failure. Elastic limit is a static property measured under a single or slow application of load, while endurance limit is a dynamic property identified through cyclic loading tests. Materials without a clear endurance limit, like aluminum, rely on fatigue strength for design, contrasting with ferrous metals that often exhibit a distinct endurance limit.

Significance in Material Science

The elastic limit represents the maximum stress a material can withstand without permanent deformation, crucial for designing components that must return to their original shape under load. The endurance limit defines the stress threshold below which a material can endure an infinite number of load cycles without failure, essential for fatigue analysis in structural applications. Understanding both limits allows engineers to predict material behavior under static and cyclic loading, optimizing durability and safety in mechanical design.

Measurement Methods for Elastic Limit

Measurement methods for the elastic limit primarily involve stress-strain testing using tensile or compression tests where the material is loaded incrementally until permanent deformation is detected. Precision instruments like extensometers or strain gauges record the deformation, identifying the elastic limit as the maximum stress before irreversible strain occurs. Advanced techniques such as digital image correlation (DIC) offer non-contact measurement, enhancing accuracy in determining the elastic limit without physical interference.

Testing Procedures for Endurance Limit

Testing procedures for the endurance limit involve subjecting a material sample to cyclic loading at a stress level below its elastic limit, often using rotating bending or tensile-compressive fatigue tests to determine the maximum stress it can withstand without failure over an extended number of cycles. The test typically measures the number of cycles to failure, or alternatively, identifies a stress amplitude at which the material can endure an essentially infinite number of cycles, often defined around 10^6 to 10^7 cycles. Precise control of stress amplitude, load frequency, and environment during testing ensures accurate determination of the endurance limit, crucial for predicting long-term fatigue performance in engineering applications.

Factors Influencing the Elastic Limit

The elastic limit of a material is influenced by factors such as temperature, strain rate, and material composition, which determine the maximum stress it can withstand without permanent deformation. Microstructural characteristics like grain size, phase distribution, and the presence of defects or impurities significantly impact the elastic limit by affecting dislocation movement. Unlike the endurance limit, which relates to cyclic loading, the elastic limit primarily depends on intrinsic material properties and environmental conditions during loading.

Variables Affecting Endurance Limit

The endurance limit is influenced by variables such as material composition, surface finish, temperature, and loading conditions, which affect its fatigue resistance under cyclic stresses. Grain size, microstructure, and presence of stress concentrators like notches or cracks also play significant roles in determining the endurance limit. Unlike the elastic limit, which is primarily dependent on the material's yield strength, the endurance limit varies with factors impacting the material's ability to withstand repeated stress without failure.

Practical Applications in Engineering

The elastic limit determines the maximum stress a material can withstand without permanent deformation, crucial for designing components like springs and beams to ensure they return to their original shape under load. The endurance limit defines the stress level below which a material can endure an infinite number of load cycles without fatigue failure, vital for rotating machinery parts, such as crankshafts and axles, subjected to repeated stresses. Engineers use the elastic limit for static load assessments and the endurance limit for fatigue life predictions, optimizing safety and longevity in structural and mechanical systems.

Conclusion: Choosing Materials Based on Limits

Selecting materials based on elastic and endurance limits depends on the application's stress conditions and lifecycle requirements. Materials with a high elastic limit are ideal for applications undergoing significant but infrequent stress, ensuring they return to their original shape without permanent deformation. For components exposed to repetitive or cyclic loads, prioritizing materials with a high endurance limit enhances fatigue resistance and prolongs service life.

Elastic limit Infographic

libterm.com

libterm.com