Dynamic balancing ensures rotating parts operate smoothly by correcting imbalances that cause vibrations and wear, enhancing machine performance and longevity. Precise measurement and adjustment techniques help maintain optimal efficiency and reduce maintenance costs. Discover how mastering dynamic balancing can significantly improve your equipment's reliability by continuing to read this article.

Table of Comparison

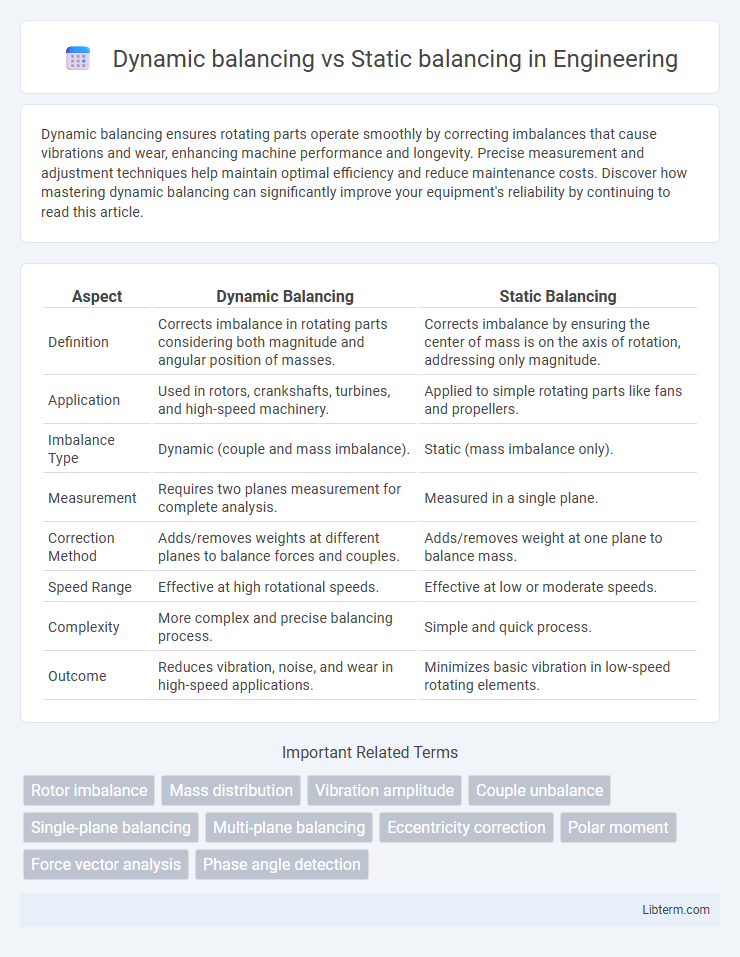

| Aspect | Dynamic Balancing | Static Balancing |

|---|---|---|

| Definition | Corrects imbalance in rotating parts considering both magnitude and angular position of masses. | Corrects imbalance by ensuring the center of mass is on the axis of rotation, addressing only magnitude. |

| Application | Used in rotors, crankshafts, turbines, and high-speed machinery. | Applied to simple rotating parts like fans and propellers. |

| Imbalance Type | Dynamic (couple and mass imbalance). | Static (mass imbalance only). |

| Measurement | Requires two planes measurement for complete analysis. | Measured in a single plane. |

| Correction Method | Adds/removes weights at different planes to balance forces and couples. | Adds/removes weight at one plane to balance mass. |

| Speed Range | Effective at high rotational speeds. | Effective at low or moderate speeds. |

| Complexity | More complex and precise balancing process. | Simple and quick process. |

| Outcome | Reduces vibration, noise, and wear in high-speed applications. | Minimizes basic vibration in low-speed rotating elements. |

Introduction to Rotational Balancing

Rotational balancing ensures smooth operation of rotating machinery by minimizing vibrations caused by mass imbalances. Static balancing corrects unbalance in a single plane, ideal for simple rotors, while dynamic balancing addresses multi-plane imbalances typical in complex or high-speed rotors. Effective rotational balancing extends equipment life, reduces wear, and enhances operational safety in industrial applications.

What is Static Balancing?

Static balancing refers to the process of balancing a rotating object without movement, ensuring the weight is evenly distributed around its axis to prevent vibration during operation. This technique involves placing the object on a pivot or knife-edge and adding or removing mass until it remains stationary in any position. Static balancing is crucial for components like fans, flywheels, and rotors to minimize wear and extend machinery lifespan.

What is Dynamic Balancing?

Dynamic balancing is a process that corrects imbalances in rotating machinery by identifying and compensating for uneven weight distribution at multiple planes along the rotor's axis. This technique measures both the magnitude and angular position of the unbalance while the rotor is in motion, ensuring that vibrations are minimized during operation. Unlike static balancing, which only addresses imbalance in a single plane, dynamic balancing provides a more comprehensive correction for complex rotors and high-speed applications.

Key Differences Between Static and Dynamic Balancing

Static balancing ensures an object's mass is evenly distributed around its rotational axis, preventing vibration when the object is stationary or rotating slowly. Dynamic balancing addresses imbalances that occur at higher rotational speeds by correcting both mass distribution and the alignment of the rotating axis, reducing wobble and vibration during operation. Key differences include static balancing focusing solely on single-plane balance, while dynamic balancing involves multi-plane analysis for comprehensive vibration control in rotating machinery.

Principles and Applications of Static Balancing

Static balancing ensures an object's center of mass aligns precisely with its axis of rotation, preventing oscillations and reducing vibration during operation. This principle is critical in applications such as rotating machine parts, including fans, turbines, and hard disk drives, where imbalance can lead to wear and noise. By maintaining equilibrium without motion, static balancing enhances performance, extends equipment life, and improves overall safety.

Principles and Applications of Dynamic Balancing

Dynamic balancing involves correcting mass distribution in rotating components to minimize vibration during operation by balancing forces and moments in multiple planes, whereas static balancing addresses mass distribution around a single plane to prevent uneven weight distribution causing vibration at rest. Principles of dynamic balancing rely on identifying and compensating for unbalanced centrifugal forces and moments generated by rotating parts, ensuring smooth rotation at all speeds. Applications of dynamic balancing include automotive driveshafts, turbine rotors, and industrial fans where high-speed rotation demands precision balancing to improve performance and reduce wear.

Pros and Cons: Static Balancing

Static balancing ensures uniform weight distribution around a rotation axis, reducing vibration and wear in components like rotors and fans. Its simplicity and cost-effectiveness make it ideal for applications with low to moderate speeds but it cannot detect unbalanced forces along the shaft's length. Limited to single-plane imbalance correction, static balancing may not suffice for high-speed or multi-plane rotating machinery requiring precise dynamic balancing.

Pros and Cons: Dynamic Balancing

Dynamic balancing offers superior accuracy by correcting imbalances in rotating machinery across multiple planes, reducing vibrations that cause wear and tear. However, it requires more complex and costly equipment compared to static balancing, making it less suitable for simpler or smaller components. Despite higher initial costs, dynamic balancing extends equipment lifespan and improves operational efficiency, justifying its use in high-speed or precision applications.

Choosing Between Static and Dynamic Balancing

Choosing between static and dynamic balancing depends on the type of rotor and its operating conditions. Static balancing corrects mass distribution along the rotor's center of gravity to prevent vibration when the rotor spins at low speeds or remains stationary, ideal for simple, symmetrical rotors. Dynamic balancing addresses imbalance forces in multiple planes, essential for high-speed rotors or those with complex geometries, ensuring smoother operation and increased machinery lifespan.

Conclusion: Optimizing Performance with Correct Balancing

Dynamic balancing addresses both mass and rotational force distribution in rotating machinery, reducing vibrations and increasing operational longevity, while static balancing corrects only mass distribution along a single plane. Correctly selecting dynamic or static balancing based on specific machinery requirements ensures optimal performance, minimizes wear, and prevents mechanical failures. Implementing the appropriate balancing technique enhances efficiency, safety, and overall productivity in industrial applications.

Dynamic balancing Infographic

libterm.com

libterm.com