Absorption refrigeration uses a heat source to drive the cooling process, relying on a refrigerant and an absorbent instead of mechanical compression. This method is energy-efficient and environmentally friendly, often utilizing waste heat or solar energy for operation. Explore the rest of the article to discover how absorption refrigeration can enhance your cooling solutions.

Table of Comparison

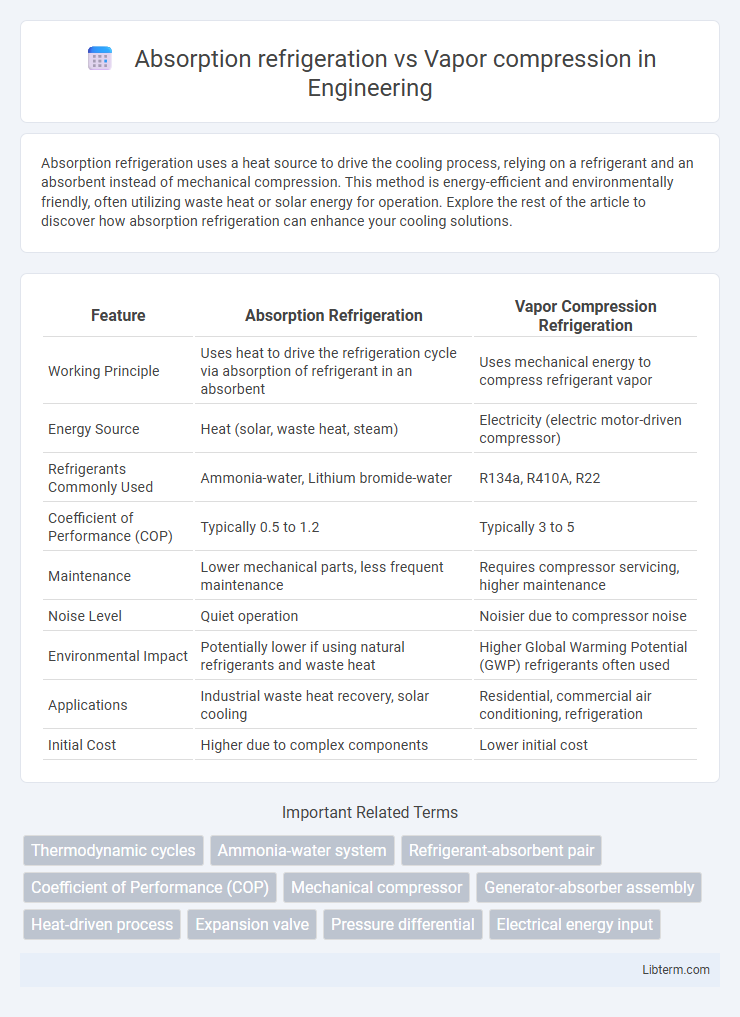

| Feature | Absorption Refrigeration | Vapor Compression Refrigeration |

|---|---|---|

| Working Principle | Uses heat to drive the refrigeration cycle via absorption of refrigerant in an absorbent | Uses mechanical energy to compress refrigerant vapor |

| Energy Source | Heat (solar, waste heat, steam) | Electricity (electric motor-driven compressor) |

| Refrigerants Commonly Used | Ammonia-water, Lithium bromide-water | R134a, R410A, R22 |

| Coefficient of Performance (COP) | Typically 0.5 to 1.2 | Typically 3 to 5 |

| Maintenance | Lower mechanical parts, less frequent maintenance | Requires compressor servicing, higher maintenance |

| Noise Level | Quiet operation | Noisier due to compressor noise |

| Environmental Impact | Potentially lower if using natural refrigerants and waste heat | Higher Global Warming Potential (GWP) refrigerants often used |

| Applications | Industrial waste heat recovery, solar cooling | Residential, commercial air conditioning, refrigeration |

| Initial Cost | Higher due to complex components | Lower initial cost |

Introduction to Refrigeration Systems

Absorption refrigeration systems utilize a heat source to drive the cooling cycle, relying on the absorption of refrigerant by a liquid absorbent, which makes them ideal for waste heat recovery and applications with limited electricity access. Vapor compression refrigeration systems operate by mechanically compressing a refrigerant vapor, providing higher efficiency and faster cooling suitable for most commercial and residential air conditioning and refrigeration needs. Understanding the fundamental differences between these systems is crucial for selecting the appropriate technology based on energy availability, environmental impact, and operational requirements.

Overview of Absorption Refrigeration

Absorption refrigeration systems utilize a heat source to drive the cooling process by circulating refrigerant absorbed in a liquid solution, often using ammonia-water or lithium bromide-water pairs. Unlike vapor compression systems that rely on mechanical compressors, absorption systems operate quietly with fewer moving parts and can use waste heat or renewable energy sources. These systems are ideal for applications where electricity is limited or when thermal energy availability is high, offering energy-efficient cooling alternatives.

Overview of Vapor Compression Refrigeration

Vapor compression refrigeration systems utilize a mechanical compressor to circulate refrigerant through evaporation, compression, condensation, and expansion phases, achieving efficient heat transfer. These systems offer higher energy efficiency and faster cooling compared to absorption refrigeration, which operates using thermal energy and a solution of refrigerant and absorbent. Commonly used in residential and commercial air conditioning and refrigeration, vapor compression technology dominates due to its compact design and greater coefficient of performance (COP).

Working Principles: Absorption vs Vapor Compression

Absorption refrigeration operates on a heat-driven cycle where a refrigerant is absorbed by a liquid solution and then separated by heat to produce cooling, relying on thermal energy instead of mechanical work. Vapor compression refrigeration uses a mechanical compressor to compress the refrigerant vapor, increasing its pressure and temperature before condensation and expansion to achieve cooling. The key difference lies in absorption systems using thermal energy for the refrigerant cycle, while vapor compression systems depend on mechanical energy input through the compressor.

Key Components Comparison

Absorption refrigeration relies on key components such as the absorber, generator, and heat source, whereas vapor compression uses a compressor, condenser, expansion valve, and evaporator. The absorber in absorption systems replaces the mechanical compressor by utilizing a refrigerant-absorbent pair like ammonia-water, improving energy efficiency when waste heat is available. Vapor compression systems depend heavily on the compressor's mechanical work to circulate refrigerant, typically using refrigerants like R-134a or R-410A, which provide faster cooling cycles but higher electrical consumption.

Energy Sources and Efficiency

Absorption refrigeration systems primarily utilize heat sources such as natural gas, solar thermal energy, or waste heat, making them ideal for applications where electricity availability is limited or expensive. Vapor compression systems rely exclusively on electrical energy to power compressors, generally achieving higher coefficient of performance (COP) between 3 and 6 compared to absorption's typical COP of 0.5 to 1.2, reflecting greater energy efficiency but less versatility in energy input options.

Environmental Impact and Sustainability

Absorption refrigeration systems utilize heat sources like solar or waste heat, significantly reducing electricity consumption and greenhouse gas emissions compared to vapor compression systems that rely heavily on electrically driven compressors powered by fossil fuels. Absorption units typically use natural refrigerants such as water or ammonia, which have negligible ozone depletion potential (ODP) and global warming potential (GWP), while vapor compression systems often use synthetic refrigerants with high GWP values. The sustainable advantage of absorption refrigeration lies in its lower environmental footprint and potential integration with renewable energy sources, making it a viable option for eco-friendly cooling solutions.

Applications and Industrial Usage

Absorption refrigeration systems are widely used in industrial applications requiring waste heat utilization, such as chemical plants and power stations, where low-grade thermal energy is available. Vapor compression refrigeration dominates commercial and residential sectors due to its higher coefficient of performance (COP) and faster cooling rates, making it ideal for HVAC systems, refrigeration units, and food processing industries. Industrial usage of absorption refrigeration often includes large-scale cooling with minimal electrical input, while vapor compression technology excels in precise temperature control and energy efficiency in smaller-scale operations.

Cost Analysis and Maintenance

Absorption refrigeration systems typically have higher initial costs due to complex components and the need for heat sources but benefit from lower operating expenses when using waste heat or solar energy. Vapor compression systems feature more straightforward design, resulting in lower upfront costs but higher electricity consumption and potentially higher long-term maintenance expenses due to compressor wear. Maintenance for absorption units often requires specialized knowledge to manage refrigerant and absorbent fluids, while vapor compression systems benefit from more widespread technician expertise and readily available parts.

Choosing the Right System: Factors to Consider

Choosing between absorption refrigeration and vapor compression systems depends on factors like energy source availability, efficiency, and environmental impact. Absorption refrigeration is ideal for applications utilizing waste heat or solar energy with lower electricity costs, offering quieter operation and fewer moving parts. Vapor compression systems provide higher cooling efficiency, faster temperature control, and are preferred when electrical power is reliable and cooling demand is high.

Absorption refrigeration Infographic

libterm.com

libterm.com