Electron beam welding uses a focused beam of high-velocity electrons to join materials with precision and minimal distortion. This process offers deep penetration, narrow welds, and is ideal for metals requiring high-quality, strong joints. Discover how electron beam welding can enhance your manufacturing projects by reading the rest of the article.

Table of Comparison

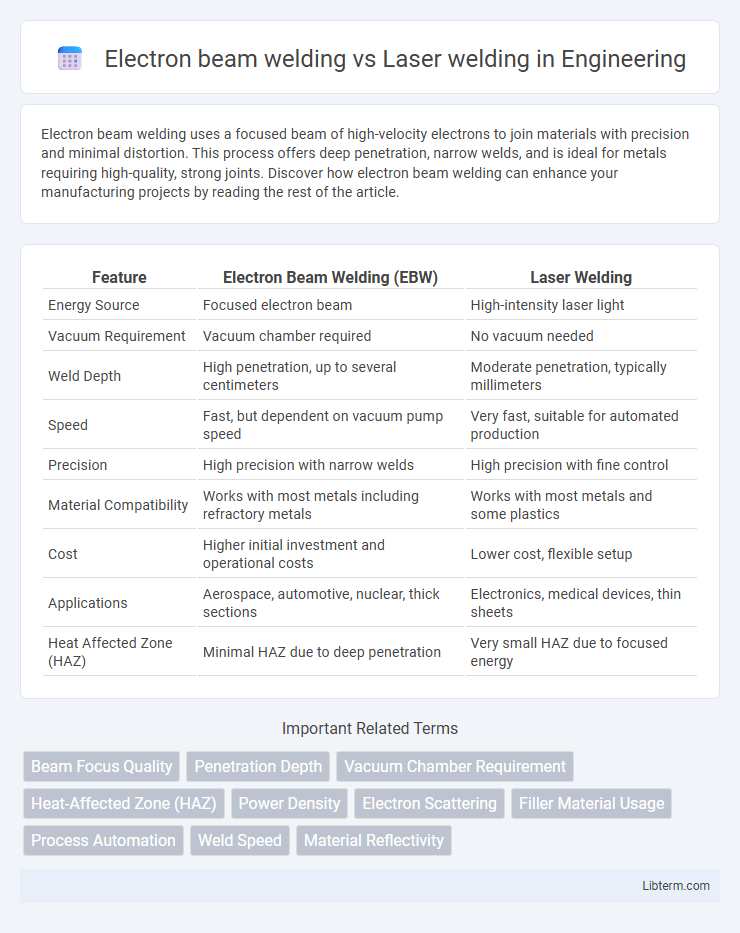

| Feature | Electron Beam Welding (EBW) | Laser Welding |

|---|---|---|

| Energy Source | Focused electron beam | High-intensity laser light |

| Vacuum Requirement | Vacuum chamber required | No vacuum needed |

| Weld Depth | High penetration, up to several centimeters | Moderate penetration, typically millimeters |

| Speed | Fast, but dependent on vacuum pump speed | Very fast, suitable for automated production |

| Precision | High precision with narrow welds | High precision with fine control |

| Material Compatibility | Works with most metals including refractory metals | Works with most metals and some plastics |

| Cost | Higher initial investment and operational costs | Lower cost, flexible setup |

| Applications | Aerospace, automotive, nuclear, thick sections | Electronics, medical devices, thin sheets |

| Heat Affected Zone (HAZ) | Minimal HAZ due to deep penetration | Very small HAZ due to focused energy |

Introduction to Electron Beam Welding and Laser Welding

Electron beam welding (EBW) employs a high-velocity beam of electrons focused on the workpiece to produce deep, narrow welds with minimal distortion, making it ideal for complex, high-precision applications in aerospace and automotive industries. Laser welding utilizes a concentrated laser light source to melt and join materials, offering precise control, high welding speed, and minimal heat-affected zones, widely applied in electronics manufacturing and medical device production. Both welding techniques rely on advanced energy sources to create strong, accurate welds but differ in beam generation, vacuum requirements, and material adaptability.

Fundamental Principles of Electron Beam vs Laser Welding

Electron beam welding utilizes a focused beam of high-velocity electrons that generate heat upon impact, enabling deep penetration and precise welds in vacuum conditions. Laser welding employs concentrated light energy to melt and join materials, offering high-speed welding with minimal thermal distortion in ambient atmospheres. Both techniques provide distinct advantages in control, penetration depth, and application environments based on their fundamental energy sources and interaction mechanisms.

Equipment and Setup Differences

Electron beam welding utilizes a vacuum chamber to focus high-velocity electrons on the workpiece, requiring sophisticated vacuum equipment and precise electron optics for beam control. Laser welding employs high-powered lasers, such as fiber or CO2 laser sources, with open-air operation and often involves less complex, more compact setups compared to electron beam systems. Equipment cost and maintenance vary significantly, with electron beam welding demanding more extensive infrastructure and shielding due to vacuum and electron containment requirements.

Material Suitability and Compatibility

Electron beam welding offers superior penetration and is ideal for welding high-thickness, high-melting-point materials such as titanium, stainless steel, and refractory metals, ensuring deep welds with minimal distortion. Laser welding excels in precision and speed, making it suitable for thin materials like aluminum, copper, and certain plastics, providing high-quality, low-heat input welds with excellent surface finish. Compatibility-wise, electron beam welding requires a vacuum environment to prevent beam scattering, limiting its use in open-air applications, whereas laser welding operates effectively in ambient conditions, offering greater flexibility across various industrial settings.

Weld Quality and Precision Comparison

Electron beam welding produces exceptionally high-quality welds with deep penetration and minimal distortion, making it ideal for critical aerospace and automotive components. Laser welding offers superior precision and control, creating narrow, high-aspect-ratio welds suited for delicate electronics and fine jewelry fabrication. Both methods provide excellent weld integrity, but electron beam welding excels in thicker materials while laser welding dominates in intricate, thin-section applications.

Depth of Penetration and Joint Types

Electron beam welding achieves significantly deeper penetration, often exceeding 50 mm, making it ideal for thick materials and complex, high-strength joints such as aerospace and automotive components. Laser welding offers more precise control with penetration depths typically ranging from 1 to 10 mm, best suited for delicate or thin materials and fine seam joints in electronics and medical devices. Both methods excel in producing high-quality, narrow welds, but electron beam welding requires a vacuum environment, whereas laser welding operates in open air or controlled atmospheres.

Process Speed and Productivity

Electron beam welding offers high process speed due to its concentrated energy source and vacuum environment, enabling deep penetration and minimal distortion. Laser welding provides even faster processing rates with precise energy delivery, suitable for thin materials and high-volume production. Both technologies significantly enhance productivity by reducing cycle times and improving weld quality in industrial applications.

Cost Implications and Economic Considerations

Electron beam welding (EBW) typically incurs higher initial equipment costs compared to laser welding due to its vacuum chamber requirements and complex setup, impacting budget allocation for manufacturers. Laser welding offers more cost-effective operations with lower maintenance expenses and greater flexibility in automation, making it suitable for high-volume production and reducing overall per-unit costs. Economic considerations also include energy consumption, with laser welding generally being more energy-efficient, thereby lowering operational expenditures over time.

Safety Considerations for Electron Beam and Laser Welding

Electron beam welding requires a high vacuum environment, significantly reducing the risk of airborne contaminants but necessitating stringent safety protocols to prevent exposure to high-energy electron radiation. Laser welding poses hazards such as severe eye and skin injuries caused by direct or reflected laser beams, demanding comprehensive protective eyewear and controlled workspaces. Both methods require specialized training and adherence to strict operational guidelines to mitigate risks associated with intense energy sources and ensure safe handling and maintenance.

Applications and Industry Use Cases

Electron beam welding excels in aerospace and automotive industries for high-precision, deep-penetration joints in thick materials like titanium and steel. Laser welding is widely used in electronics manufacturing and medical device production, offering fast, accurate welding for delicate, thin metals such as stainless steel and aluminum. Both processes are crucial in industries requiring minimal thermal distortion and high-strength welds but differ in cost, equipment complexity, and vacuum requirements.

Electron beam welding Infographic

libterm.com

libterm.com