Thermoelectric materials efficiently convert heat into electricity through the Seebeck effect, offering promising applications in waste heat recovery and renewable energy. Their performance depends on optimizing electrical conductivity, thermal conductivity, and the Seebeck coefficient to maximize energy conversion efficiency. Discover how advancements in thermoelectric materials can enhance your energy solutions by reading the full article.

Table of Comparison

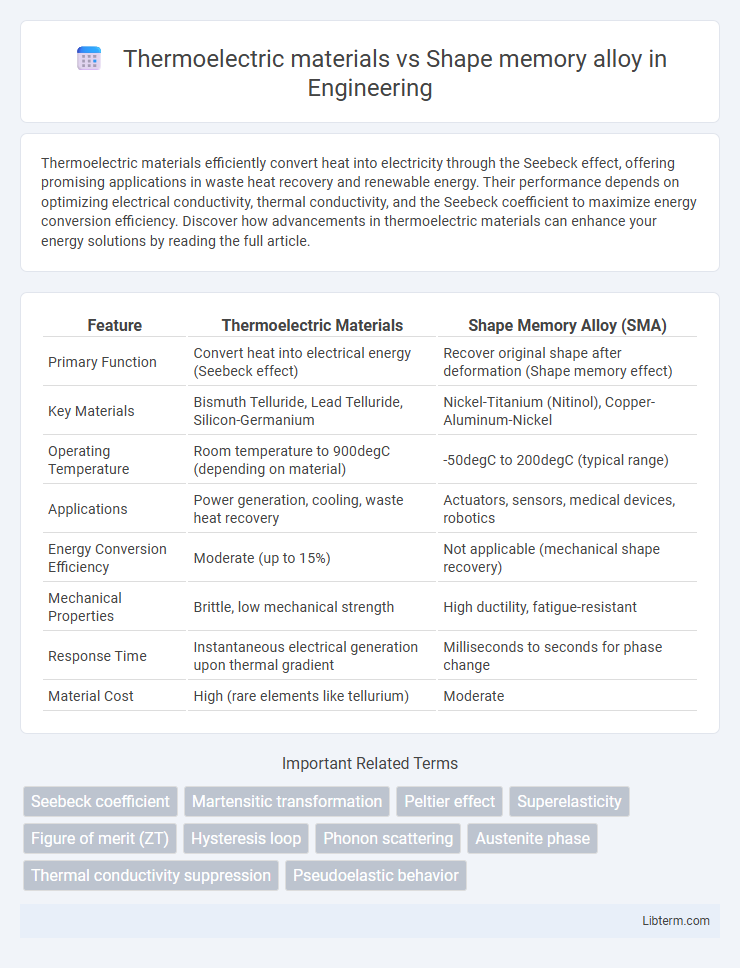

| Feature | Thermoelectric Materials | Shape Memory Alloy (SMA) |

|---|---|---|

| Primary Function | Convert heat into electrical energy (Seebeck effect) | Recover original shape after deformation (Shape memory effect) |

| Key Materials | Bismuth Telluride, Lead Telluride, Silicon-Germanium | Nickel-Titanium (Nitinol), Copper-Aluminum-Nickel |

| Operating Temperature | Room temperature to 900degC (depending on material) | -50degC to 200degC (typical range) |

| Applications | Power generation, cooling, waste heat recovery | Actuators, sensors, medical devices, robotics |

| Energy Conversion Efficiency | Moderate (up to 15%) | Not applicable (mechanical shape recovery) |

| Mechanical Properties | Brittle, low mechanical strength | High ductility, fatigue-resistant |

| Response Time | Instantaneous electrical generation upon thermal gradient | Milliseconds to seconds for phase change |

| Material Cost | High (rare elements like tellurium) | Moderate |

Introduction to Thermoelectric Materials and Shape Memory Alloys

Thermoelectric materials convert temperature differences directly into electrical voltage, enabling energy harvesting and solid-state cooling with high reliability and no moving parts. Shape memory alloys (SMAs) exhibit unique properties like superelasticity and the ability to return to pre-deformed shapes upon heating, making them essential in actuators, medical devices, and aerospace applications. Both thermoelectric materials and SMAs rely on specific phase transformations, with thermoelectrics optimizing electrical conductivity and thermal gradients, while SMAs depend on martensitic transformation for functional performance.

Fundamental Principles: How Each Material Works

Thermoelectric materials operate based on the Seebeck effect, converting temperature differences directly into electric voltage by manipulating charge carriers within semiconductors. Shape memory alloys rely on a reversible martensitic phase transformation, enabling the material to return to a predetermined shape when exposed to specific temperature changes. Both materials exploit temperature-dependent physical phenomena but differ fundamentally in energy conversion versus mechanical actuation mechanisms.

Key Material Properties Comparison

Thermoelectric materials exhibit high Seebeck coefficients, low thermal conductivity, and good electrical conductivity, enabling efficient heat-to-electricity conversion. Shape memory alloys demonstrate unique phase transformation behavior, high elastic strain capacity, and significant mechanical strength, allowing reversible deformation and shape recovery. While thermoelectric materials prioritize electrical and thermal transport properties, shape memory alloys emphasize mechanical and transformational characteristics for actuation and sensing applications.

Applications in Modern Technology

Thermoelectric materials generate electricity from temperature gradients and are widely used in waste heat recovery and power generation in automotive and aerospace industries. Shape memory alloys, known for their ability to return to a predefined shape upon heating, find applications in biomedical devices, actuators, and robotics for precise movement control. Both materials enhance energy efficiency and functionality in modern technology, leveraging unique physical properties for innovative solutions.

Energy Conversion Efficiency

Thermoelectric materials convert temperature differences directly into electrical energy with energy conversion efficiencies typically ranging between 5% and 8%, depending on the material's figure of merit (ZT). Shape memory alloys primarily convert thermal energy to mechanical work through phase transformations, with lower overall energy conversion efficiency often below 10%. Advances in thermoelectric materials focus on increasing ZT values above 2 to enhance efficiency, while shape memory alloys emphasize optimizing hysteresis and transformation temperatures to improve performance.

Mechanical vs. Electrical Performance

Thermoelectric materials excel in electrical performance by converting temperature gradients directly into electrical energy, showcasing high Seebeck coefficients and electrical conductivity but often suffer from limited mechanical flexibility and brittleness. Shape memory alloys demonstrate superior mechanical performance with remarkable elasticity, fatigue resistance, and the ability to recover large strains through phase transformations, yet their electrical conductivity is comparatively low, restricting their use in electrical applications. Balancing these properties, thermoelectric materials prioritize energy conversion efficiency, while shape memory alloys emphasize mechanical adaptability and structural resilience.

Temperature Stability and Operating Ranges

Thermoelectric materials exhibit stable performance across moderate temperature ranges, typically from -200degC to 500degC, making them suitable for energy conversion in automotive and industrial applications. Shape memory alloys maintain functionality within narrower temperature windows, often between -50degC and 150degC, relying on phase transformation for actuation rather than thermal stability. Temperature stability in thermoelectric materials is critical for sustained efficiency, while shape memory alloys prioritize precise operating ranges to enable predictable mechanical response.

Recent Advances in Material Development

Recent advances in thermoelectric materials have focused on improving their figure of merit (ZT) through nanostructuring and doping techniques, enhancing energy conversion efficiency for waste heat recovery. Shape memory alloys (SMAs) have seen breakthroughs in alloy composition and microstructural control, resulting in improved fatigue resistance and higher actuation temperatures suitable for biomedical and aerospace applications. Both material classes benefit from computational modeling and additive manufacturing to tailor properties at the atomic scale, enabling multifunctional device integration.

Challenges and Limitations

Thermoelectric materials face challenges such as low conversion efficiency, thermal conductivity management, and material degradation at high temperatures, limiting widespread application in energy harvesting. Shape memory alloys encounter issues with fatigue life, limited strain recovery, and sensitivity to temperature variations, which restrict their performance and durability in cyclic applications. Both materials demand advancements in composition and structural engineering to overcome these intrinsic limitations for practical and commercial use.

Future Trends and Research Prospects

Thermoelectric materials are advancing rapidly with a focus on enhancing conversion efficiency through nanostructuring and novel material compositions such as skutterudites and half-Heusler alloys, enabling sustainable energy harvesting from waste heat. Shape memory alloys (SMAs) research emphasizes improving fatigue resistance and functional stability, with innovations in high-entropy alloys and additive manufacturing techniques expanding their applicability in biomedical and aerospace sectors. Future trends highlight integrating thermoelectric materials and SMAs into multifunctional devices, enabling smart systems that leverage energy conversion and mechanical actuation for next-generation wearable electronics and autonomous sensors.

Thermoelectric materials Infographic

libterm.com

libterm.com