Event Tree Analysis (ETA) systematically evaluates potential outcomes following an initiating event by mapping possible success or failure paths of safety systems and controls. This method helps identify critical components and assess the probability of various accident scenarios, enhancing risk management strategies. Discover how ETA can strengthen your safety assessments by exploring the detailed process in the rest of this article.

Table of Comparison

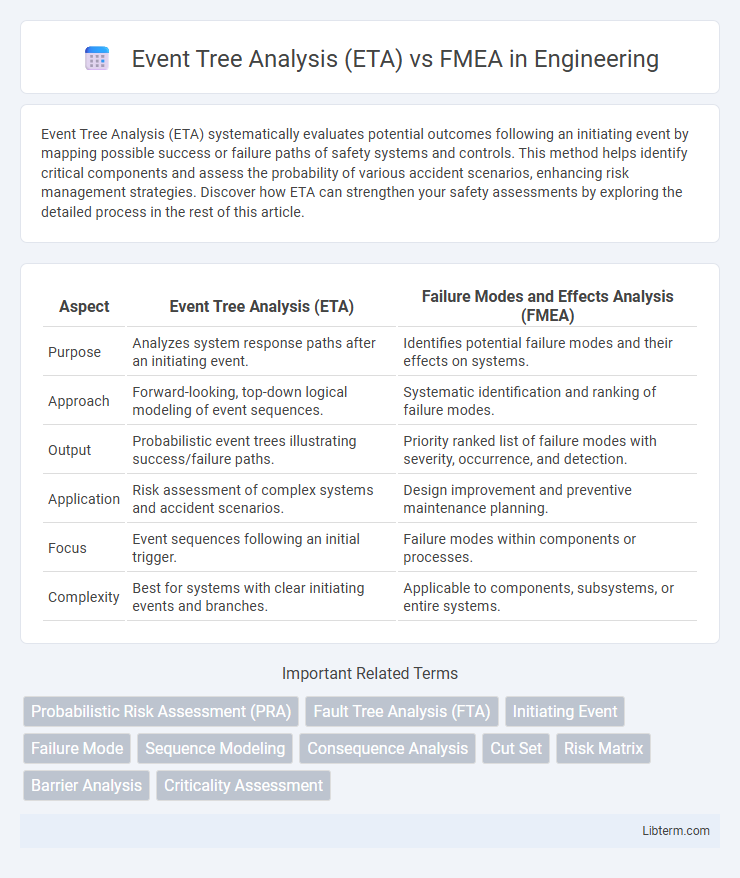

| Aspect | Event Tree Analysis (ETA) | Failure Modes and Effects Analysis (FMEA) |

|---|---|---|

| Purpose | Analyzes system response paths after an initiating event. | Identifies potential failure modes and their effects on systems. |

| Approach | Forward-looking, top-down logical modeling of event sequences. | Systematic identification and ranking of failure modes. |

| Output | Probabilistic event trees illustrating success/failure paths. | Priority ranked list of failure modes with severity, occurrence, and detection. |

| Application | Risk assessment of complex systems and accident scenarios. | Design improvement and preventive maintenance planning. |

| Focus | Event sequences following an initial trigger. | Failure modes within components or processes. |

| Complexity | Best for systems with clear initiating events and branches. | Applicable to components, subsystems, or entire systems. |

Introduction to Event Tree Analysis (ETA) and FMEA

Event Tree Analysis (ETA) systematically models event sequences following an initiating fault, mapping potential outcomes using a forward, deductive approach to assess risk and safety in engineering systems. Failure Modes and Effects Analysis (FMEA) identifies possible failure modes within components or processes, evaluating their causes and impacts to prioritize corrective actions through a structured, component-level methodology. Both techniques contribute to reliability engineering, with ETA emphasizing event progression and FMEA focusing on failure identification and mitigation.

Core Principles of Event Tree Analysis (ETA)

Event Tree Analysis (ETA) systematically explores possible event sequences following an initial failure, emphasizing forward logic and probabilistic branching to assess accident scenarios and system reliability. Unlike Failure Mode and Effects Analysis (FMEA), which focuses on identifying potential component failures and their effects, ETA uses event sequences to model the progression and outcomes of failures over time. Core principles of ETA include constructing logical event sequences, quantifying the probability of each branch, and evaluating the impact of safety systems on mitigating adverse outcomes.

Fundamental Concepts of Failure Mode and Effects Analysis (FMEA)

Failure Mode and Effects Analysis (FMEA) is a systematic approach used to identify potential failure modes within a system, assess their causes and effects, and prioritize risks based on severity, occurrence, and detection rankings. FMEA focuses on early detection of design or process vulnerabilities by analyzing individual components or steps, emphasizing prevention and mitigation of specific failure causes. Unlike Event Tree Analysis (ETA), which models event sequences and outcomes probabilistically, FMEA provides a detailed, qualitative assessment of failure modes to improve reliability and safety in product development or manufacturing processes.

Methodological Differences Between ETA and FMEA

Event Tree Analysis (ETA) systematically explores possible sequences of events following an initiating incident to assess the likelihood of various outcomes, using a forward-looking, deductive approach. In contrast, Failure Modes and Effects Analysis (FMEA) identifies potential failure modes within a system, examines their causes and effects, and prioritizes them based on severity, occurrence, and detection, utilizing a bottom-up, inductive methodology. ETA emphasizes probabilistic risk assessment of event sequences, while FMEA focuses on qualitative evaluation and prioritization of individual component failures.

Advantages of Event Tree Analysis (ETA) in Risk Assessment

Event Tree Analysis (ETA) offers a dynamic approach to risk assessment by mapping out multiple possible outcomes from an initiating event, providing a clear visualization of systemic failure paths that FMEA may not detail. ETA excels in quantifying probabilities of sequential events and assessing complex interactions within safety-critical systems, enhancing decision-making in industries like nuclear power, aerospace, and chemical processing. Its capability to integrate conditional probabilities and model logical event relationships enables comprehensive evaluation of risk scenarios, optimizing mitigation strategies more effectively than the failure-mode-focused FMEA.

Benefits of FMEA for System Reliability

Failure Modes and Effects Analysis (FMEA) enhances system reliability by systematically identifying potential failure modes and assessing their impact on system performance, enabling proactive mitigation strategies. FMEA prioritizes risks based on severity, occurrence, and detectability, helping maintenance teams allocate resources effectively to prevent failures. This structured approach supports continuous improvement and reduces downtime by addressing vulnerabilities early in the design and operational phases.

Key Applications of ETA Across Industries

Event Tree Analysis (ETA) is extensively used in nuclear power, aerospace, and chemical processing industries to systematically evaluate potential accident scenarios and their probabilities, enabling risk mitigation strategies. ETA helps identify event sequences stemming from an initiating fault, supporting safety assessments and emergency response planning. Compared to FMEA, which focuses on component-level failure modes, ETA provides a broader event-sequence analysis critical for evaluating system safety and reliability under complex operational conditions.

Typical Use Cases for FMEA Implementation

FMEA (Failure Modes and Effects Analysis) is typically implemented in design and manufacturing processes to systematically identify potential failure modes and prioritize mitigation strategies, enhancing product reliability and safety. It is commonly used in automotive, aerospace, medical devices, and electronics industries to prevent defects and ensure compliance with quality standards such as ISO 9001 and ISO 13485. Event Tree Analysis (ETA), by contrast, is more focused on evaluating the probability and consequences of initiating events in safety-critical systems, often applied in nuclear power, chemical processing, and risk management fields.

ETA vs FMEA: Comparative Strengths and Limitations

Event Tree Analysis (ETA) excels in mapping sequences of events following an initiating fault, providing a visual, logical structure to assess system responses and potential outcomes, ideal for dynamic or temporal failure analysis. Failure Mode and Effects Analysis (FMEA) systematically identifies potential failure modes within components and evaluates their impacts and severities, prioritizing risks primarily based on occurrence, detection, and impact scores, which suits design-phase risk management. ETA offers superior insight into event propagation and conditional dependencies, while FMEA provides detailed, component-level diagnostics but may overlook complex event interactions and sequence dependencies inherent in system failures.

Selecting the Right Analysis Method for Your Project

Event Tree Analysis (ETA) excels in visualizing potential event sequences stemming from an initiating incident, making it ideal for projects requiring detailed probabilistic risk assessments of system failures. Failure Modes and Effects Analysis (FMEA) systematically identifies and prioritizes potential failure modes and their impacts on system components, suited for early design phases to enhance reliability. Selecting between ETA and FMEA depends on project goals: use ETA for dynamic system risk scenarios and FMEA for comprehensive failure identification and mitigation during development.

Event Tree Analysis (ETA) Infographic

libterm.com

libterm.com