Slip rings enable the transmission of electrical signals and power between stationary and rotating components, ensuring seamless operation in rotating machinery. They are crucial in applications such as wind turbines, robotics, and medical equipment where continuous rotation and data transfer are required. Discover how slip rings can enhance your system's performance and learn about their types, applications, and maintenance in the full article.

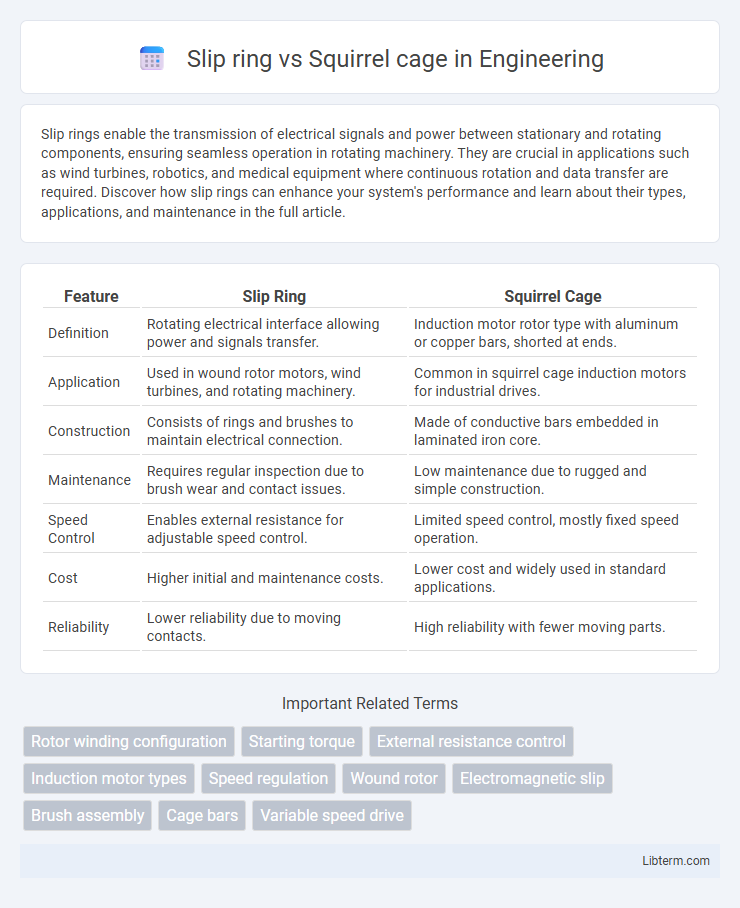

Table of Comparison

| Feature | Slip Ring | Squirrel Cage |

|---|---|---|

| Definition | Rotating electrical interface allowing power and signals transfer. | Induction motor rotor type with aluminum or copper bars, shorted at ends. |

| Application | Used in wound rotor motors, wind turbines, and rotating machinery. | Common in squirrel cage induction motors for industrial drives. |

| Construction | Consists of rings and brushes to maintain electrical connection. | Made of conductive bars embedded in laminated iron core. |

| Maintenance | Requires regular inspection due to brush wear and contact issues. | Low maintenance due to rugged and simple construction. |

| Speed Control | Enables external resistance for adjustable speed control. | Limited speed control, mostly fixed speed operation. |

| Cost | Higher initial and maintenance costs. | Lower cost and widely used in standard applications. |

| Reliability | Lower reliability due to moving contacts. | High reliability with fewer moving parts. |

Introduction to Slip Ring and Squirrel Cage Motors

Slip ring motors utilize external resistors connected through slip rings to control starting torque and current, making them ideal for high-load applications. Squirrel cage motors feature a robust rotor design with aluminum or copper bars short-circuited by end rings, providing simplicity, durability, and low maintenance. Both motor types serve distinct industrial functions, with slip ring motors offering adjustable speed control, while squirrel cage motors excel in reliability and efficiency.

Construction and Design Differences

Slip ring motors feature a rotor with windings connected to external resistors via slip rings, allowing variable resistance control during startup. Squirrel cage motors have a rotor made of laminated iron core with aluminum or copper bars short-circuited by end rings, offering a rugged and maintenance-free design. The slip ring motor's rotor windings enable better starting torque, while the squirrel cage's simple construction ensures durability and lower manufacturing costs.

Working Principle Comparison

Slip rings operate by transmitting electrical power through rotating contacts, allowing current to flow continuously between stationary and rotating parts via conductive brushes. In contrast, squirrel cage rotors function based on electromagnetic induction, where the rotating magnetic field induces current in the rotor bars, generating torque without direct electrical connections. The slip ring design enables external resistance control for starting and speed regulation, while the squirrel cage rotor offers a simpler, maintenance-free construction with fixed speed characteristics.

Key Advantages of Slip Ring Motors

Slip ring motors provide superior starting torque and smooth control of speed, making them ideal for heavy-duty applications such as cranes and hoists. Their ability to handle high starting currents with reduced power consumption enhances operational efficiency. Slip ring motors also allow external resistance adjustments in the rotor circuit, improving motor performance and minimizing mechanical stress during startup.

Benefits of Squirrel Cage Motors

Squirrel cage motors offer robust construction and low maintenance due to their simple rotor design without brushes or slip rings, significantly reducing operational downtime. Their high efficiency and reliability make them ideal for continuous industrial applications where consistent performance is essential. The absence of external connections in squirrel cage motors enhances durability and decreases the risk of mechanical failure compared to slip ring motors.

Typical Applications: Slip Ring vs Squirrel Cage

Slip ring motors are typically used in applications requiring high starting torque and variable speed control, such as cranes, hoists, and conveyors. Squirrel cage motors dominate in fixed-speed industrial processes like pumps, fans, and compressors, where durability and low maintenance are critical. The slip ring's ability to introduce external resistances for smooth start contrasts with the squirrel cage's simple, rugged design favored in continuous operation environments.

Performance Efficiency Analysis

Slip rings provide adjustable rotor resistance, enabling improved starting torque and controlled speed regulation, which enhances performance in variable load conditions. Squirrel cage rotors, known for their robust construction and low maintenance, deliver high efficiency at rated speed but lack speed control flexibility, potentially reducing efficiency under fluctuating loads. Performance efficiency analysis shows slip rings excel in applications requiring variable speed and torque control, while squirrel cage motors offer superior energy efficiency in constant speed operations.

Maintenance and Cost Considerations

Slip ring motors require regular inspection and maintenance of brushes and slip rings, leading to higher downtime and labor costs compared to squirrel cage motors, which have a rugged, brushless design demanding minimal maintenance. The initial cost of slip ring motors is generally higher due to their complex components, while squirrel cage motors offer a more cost-effective solution with longer service intervals and reduced maintenance expenses. Evaluating long-term operational costs, squirrel cage motors provide better value for applications prioritizing reliability and low upkeep.

Choosing the Right Motor for Your Needs

Selecting between slip ring and squirrel cage motors depends on application requirements such as starting torque, speed control, and maintenance. Slip ring motors offer high starting torque and adjustable speed, ideal for heavy-duty loads and variable speed operations, while squirrel cage motors provide simplicity, reliability, and low maintenance for constant speed applications. Evaluating factors like load type, control complexity, and operational environment ensures optimal motor performance and efficiency.

Conclusion: Slip Ring vs Squirrel Cage

Slip ring motors offer adjustable starting torque and speed control through external resistance, making them ideal for heavy-load applications requiring smooth starts, while squirrel cage motors provide robust, low-maintenance operation with higher efficiency and simpler construction suited for general industrial use. The slip ring motor's capability for variable starting characteristics contrasts with the squirrel cage's fixed-speed performance and lower initial cost. Selecting between slip ring and squirrel cage motors depends on application-specific demands such as starting torque, speed control needs, maintenance preferences, and overall operational efficiency.

Slip ring Infographic

libterm.com

libterm.com